Italy-based manufacturing service bureau CRP Meccanica has signed an exclusive distribution agreement with 3D printer OEM VELO3D to supply the Italian market with VELO’s metal 3D printers.

Having also become an account distributor for the wider European region, CRP is set to provide its customers with sales and after-sales support, maintenance services, and even direct technical support during the production phase.

Franco Cevolini, President and CTO of CRP Meccanica, states, “We are creating a revolution in manufacturing technology. The experience and credibility the whole world recognizes in CRP Meccanica will help VELO transform the Italian and European metal 3D printing market. We are ready to embrace this new cutting-edge technology, combining it with the expertise gained over 50 years of activity serving the most demanding industrial sectors and delivering extraordinary results.”

SupportFree 3D printing with VELO

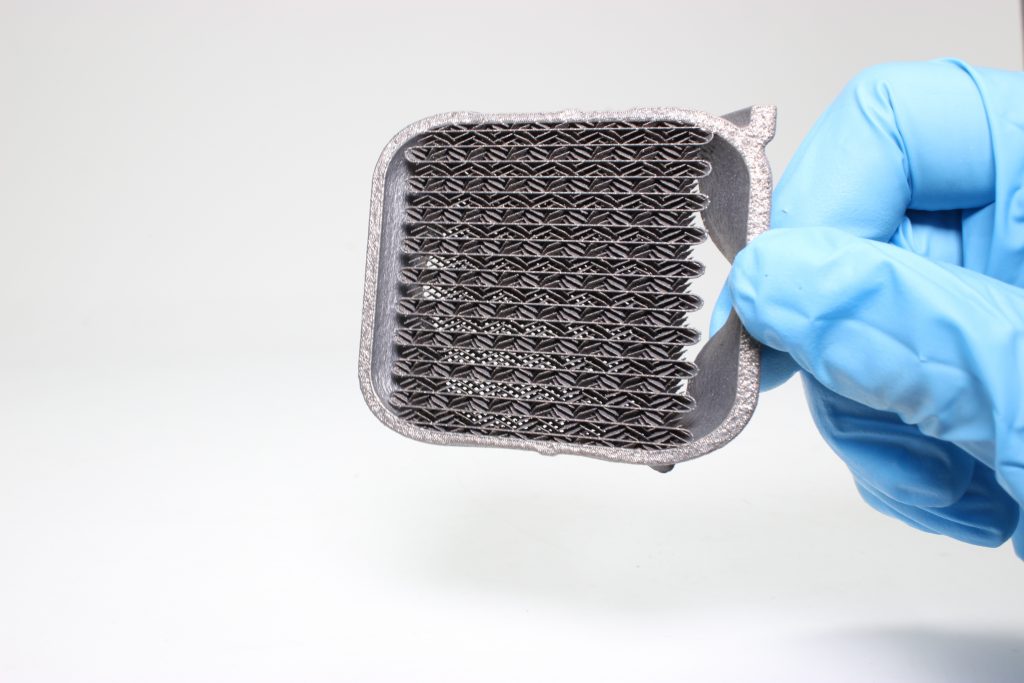

VELO’s laser powder bed fusion systems, such as the flagship Sapphire 3D printer, are unique in that they feature the company’s proprietary SupportFree technology. The technique allows engineers and designers to escape from the constraints of Design for Additive Manufacturing (DfAM) practices, enabling part designs with support-free horizontal overhangs and cavities. In contrast, most comparable industrial metal 3D printers require support structures on overhangs shallower than about 45°, placing a cap on true geometric freedom.

The partners believe the technology could have major implications in industries such as aerospace, oil and gas, and even motorsport, with components such as shrouded impellers, heat exchangers, and manifolds to name a few. Impellers in particular are expected to be chief beneficiaries as they typically can’t be economically printed without some major design modifications to accommodate for support removal in post-processing.

Cevolini adds, “I strongly believe in this project. VELO’s Sapphire Metal Additive Manufacturing solution is the next generation in metal laser powder bed fusion, is a real game-changer, and can make the difference in many high-level industrial fields. Metal AM systems must address the challenge of support structures that are added to parts. This is a constraint: these supports need to be removed so this requirement adds steps throughout the workflow that negatively affect time, cost and quality. VELO has solved the issue.”

Two decades of metal 3D printing

With over 20 years of experience in working with metal additive manufacturing systems, CRP Meccanica will act as the bridge connecting Italy to support-free metal production. The company has also stated plans to launch a dedicated 3D printing production area for customers that aren’t quite ready to invest in a VELO3D machine. Dubbed the ‘technopole’, the facility will allow customers to leverage VELO’s 3D printing capabilities with the help of CRP’s own in-house manufacturing team.

Some of these customers may very well come from the aerospace sector, as aircraft manufacturer Boom Supersonic recently rolled out its XB-1 aircraft for the first time, featuring a number of critical components 3D printed on a Sapphire system. Unveiled at the firm’s hangar in Centennial, Colorado, the supersonic jet sports a total of 21 additively manufactured parts, most of which can be found in the engine.

Elsewhere, in the semiconductor sector, VELO has previously announced a joint development agreement with semiconductor specialist Lam Research to advance 3D metal printing for electronics applications. By first developing new novel metal alloys for use with the Sapphire, Lam will be able to use the system to 3D print proprietary wafer fabrication tooling.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a rendering of a Sapphire 3D printer production facility. Image via VELO3D.