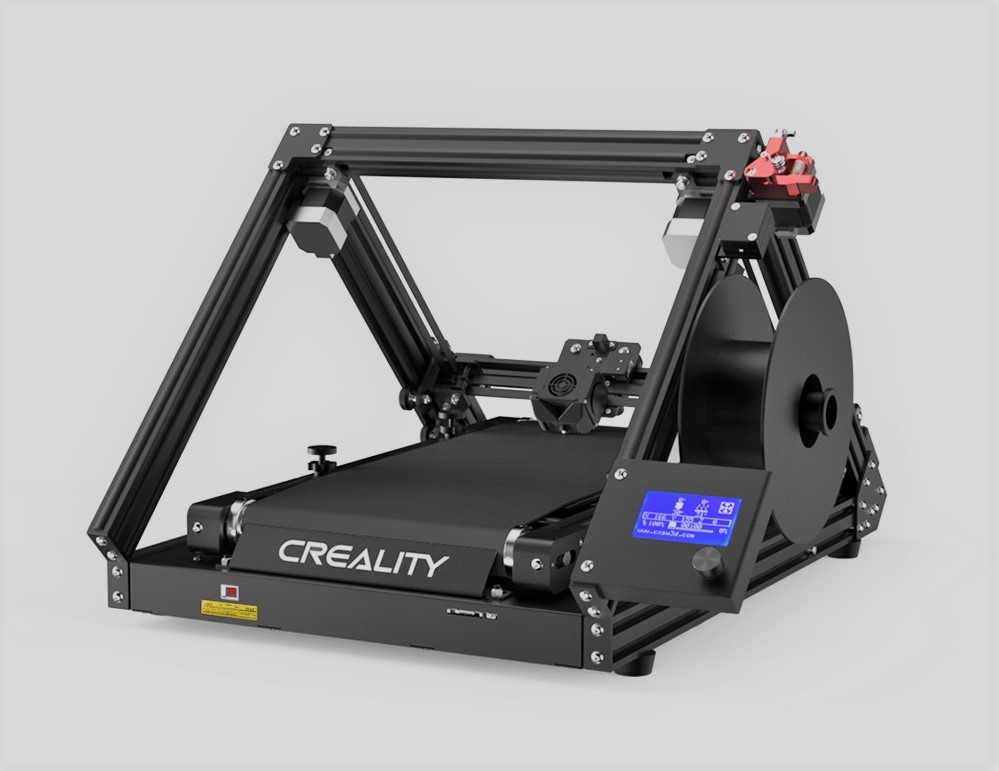

Chinese 3D printer manufacturer Creality has launched a Kickstarter campaign for its latest FDM system, the CR-30.

Also dubbed the 3DPrintMill, the conveyor belt-based machine was developed in collaboration with tech YouTuber Naomi Wu, and has already surpassed $1M in crowdfunding. Seeing as the CR-30 operates on a belt, it features a build volume of 200 x 170 x (theoretically) infinite millimeters. As such, it’s primarily aimed at designers, SMEs, and anyone else looking to replace their print farms with a hands-free continuous printing engine.

The 3DPrintMill / CR-30

Creality’s latest machine comes packaged in four separate parts – the base, front, rear, and control panel. Using the allen keys and tools included with the printer, it should only take around half an hour to assemble the whole thing into a usable piece of kit. The all-metal frame weighs 16.5kg, and is designed to dampen any and all vibrations from the Core-XY motion gantry. The hotend sits at 45º and has a maximum temperature of 240ºC, with claims that it can print with materials such as TPU and PETG. The company has also stated that it plans to launch an optional direct drive extruder conversion kit in the near future.

The Z-axis conveyor belt is made of nylon, and is expected to last several years before needing a replacement. Extra belts can be purchased for $45 and swapped out in around ten minutes. Looking underneath the belt, there is a 220W aluminum print bed capable of a maximum temperature of 100ºC, which should provide ample adhesion for the polymer parts above. The bed assembly as a whole can be releveled using a series of top-mounted knobs lining the outer edges of the conveyor belt.

Internally, the CR-30 packs an “ultra-quiet” 32-bit motherboard. Connectivity options comprise a USB slot and SD card reader, and the machine even has a smart filament detector with print resume functionality. In situations where the power cuts off or the filament spool runs dry, the system will pause the print until it’s safe to resume from where it left off.

The CrealityBelt slicer

Naturally, Creality is also offering a brand new slicing software designed specifically for the CR-30. CrealityBelt can be used to slice a model of any length, but it can also slice multiple models in a line for a series build. Included in the program is a set of ready-made slicing profiles developed by slicer expert Tom Jackson (aka FilamentFrenzy), who is well-known in the open-source community.

To complement the slicer, Creality also enlisted Scott Lahteine, the maintainer of the Open Source Marlin project, to code the firmware for the CR-30. In true open-source fashion, the firmware is compliant with the GPL and is accessible to any users that may want to tinker around with it.

Technical specifications and pricing

Below are the technical specifications for the Creality 3DPrintMill / CR-30. Pledges for the machine begin at a discounted rate of $538. The Kickstarter campaign will continue to run until December 18, after which the system will retail at $999. Deliveries are expected to commence in May 2021.

| Build volume | 200 x 170 x infinite mm |

| Machine dimensions | 535 x 656 x 410 mm |

| Max. nozzle temperature | 240°C |

| Max. bed temperature | 100°C |

| Weight | 16.5 kg |

| Nozzle diameter | 0.4 mm |

| Layer thickness | 0.1 – 0.4 mm |

| File transfer | USB/SD |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Creality CR-30 3D printer. Photo via Creality.