CraftUnique, the Hungarian 3D printer manufacturer, has introduced a new line of systems in its CraftBot series of 3D printers. Named CraftBot Flow, this new generation of FFF 3D printers will comprise a total of four different systems: two single extruder and two independent dual extruder (IDEX) iterations.

Set to premiere at this year’s Formnext, the new 3D printers consist of the CraftBot Flow, Flow XL, Flow IDEX and Flow IDEX XL systems. CraftUnique has designed the new 3D printers with a focus on efficiency and reliability, equipping them with innovative features and its own proprietary technology which was the result of soliciting pro active feedback from the marketplace. Each member of the CraftBot Flow family is “inspired” by the marketplace and designed to provide its own individual benefits.

Creating a reliable, plug&play 3D printing solution

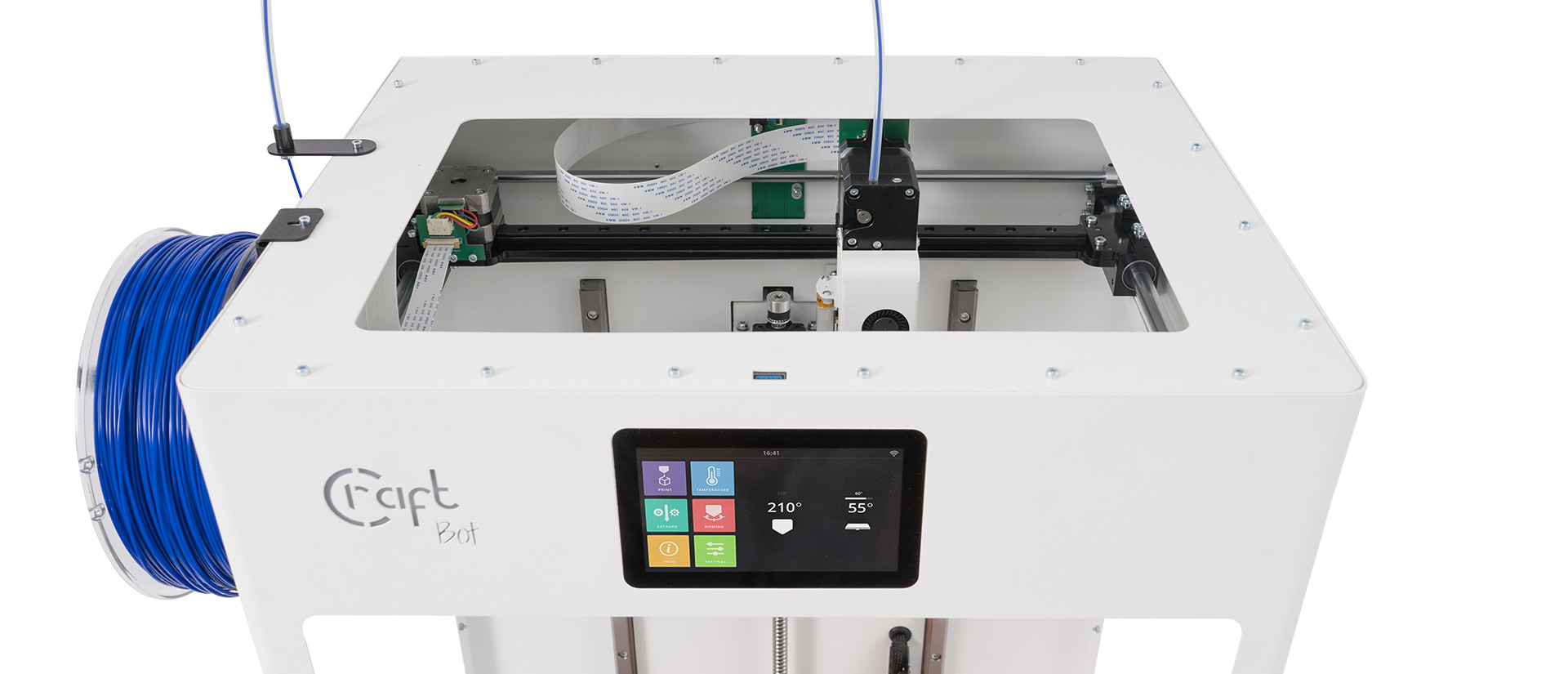

Based in Budapest, CraftUnique aims to provide user-friendly, ‘plug and play’ 3D printers that respond to its customer’s needs. The company launched its first CraftBot 3D printer in 2014, and has since released several newer systems, including the CraftBot 3, XL and Plus.

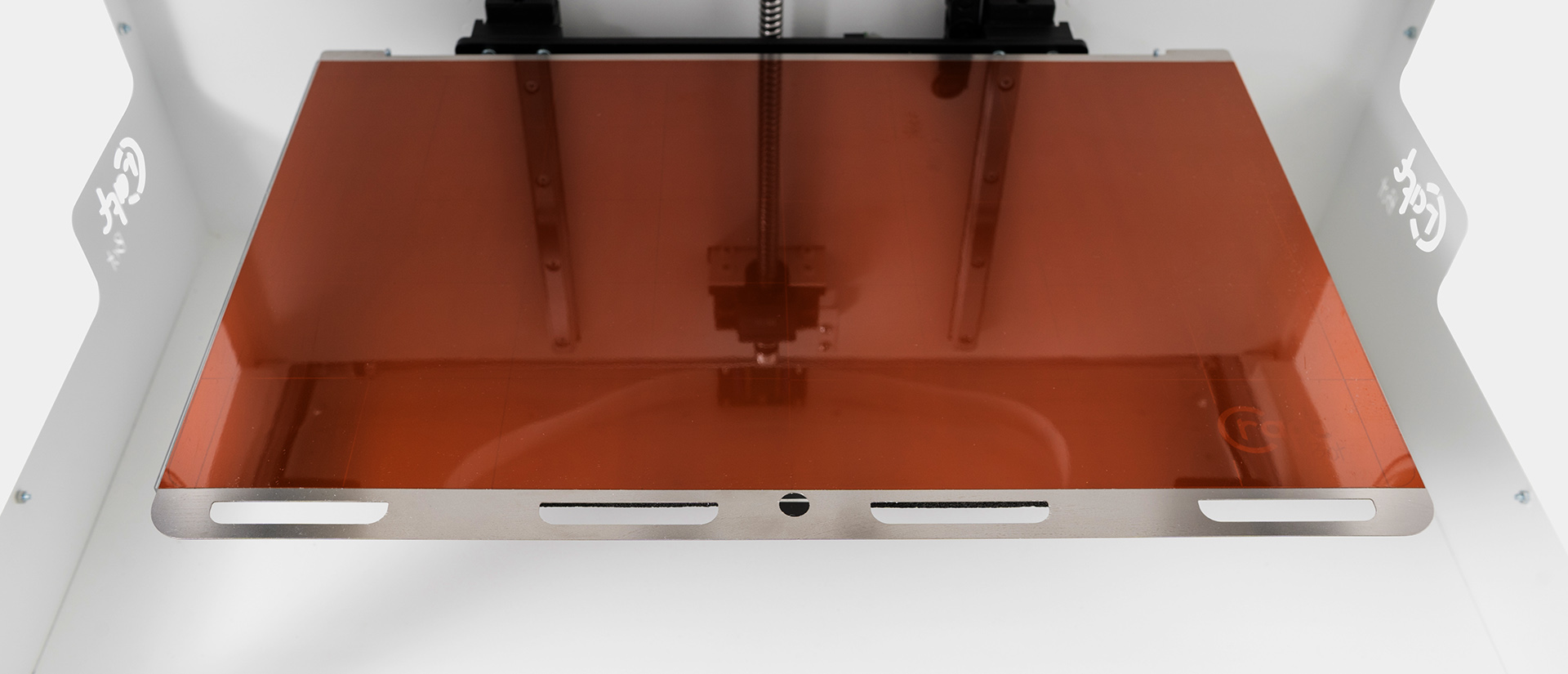

With the new CraftBot Flow generation, CraftUnique has sought to upgrade its formula with the implementation of a multitude of features. This includes a proprietary removable spring bed that combines metal, tempered glass and Kapton polyimide film to ensure maximum sticking during the 3D printing process. To help make part removal easy, the heated bed includes a flexible top board.

CraftBot Flow 3D printers also come equipped with a mesh bed leveling system using the latest BLTouch version, to help simplify the calibration process. Single extruder iterations include automatic XY calibration, whereas the IDEX printers have semi-automatic, electronically aided Z calibration as well. CraftUnique has also included a 360 fan duct, and the ability to pause and resume a print job.

Within the Flow 3D printers is a 32 Bit speed motherboard, for increased accuracy and precision when 3D printing, alongside a Raspberry Pi engine for fast response times and a unified user interface on a 5 inch color touch screen.

To improve the reliability of the systems, CraftUnique has designed the body using a reinforced double-shell structure and robust extruded aluminum profiles along the Z-axis. The CraftBot Flow family also comes installed with a new filament monitoring system that is intended to reduce breakdowns caused by filament errors, and an all-metal hotend for improved print quality.

The CraftBot Flow 3D printer family members

The CraftBot Flow generation of 3D printers is designed for both professional and beginner users. CraftUnique’s single extruder solution, the CraftBot Flow, is a compact 3D printer with a build volume of 300 x 200 x 250 mm, intended for everyday use in the engineering, machinery, prototyping and design fields. With its size, the Flow is still larger than 3D printers typically made for makers and hobbyists (This market is served by CraftUnique in the CraftBot Glass which has a volume of 220 x 200 x 200 mm) The Flow features a print speed of up to 200 mm/s, with an operating nozzle temperature of up to 300 degrees celsius. The operating heated build plate temperature is between 60 and 110 degrees celsius.

For producing larger 3D printed parts, CraftUnique created a bigger system, known as the CraftBot Flow XL. Aside from the increased build size of 300 x 200 x 500 mm, the specs are the same as its smaller counterpart. Again, the volume offered by the Flow XL is typically larger than other single extrusion systems on the market.

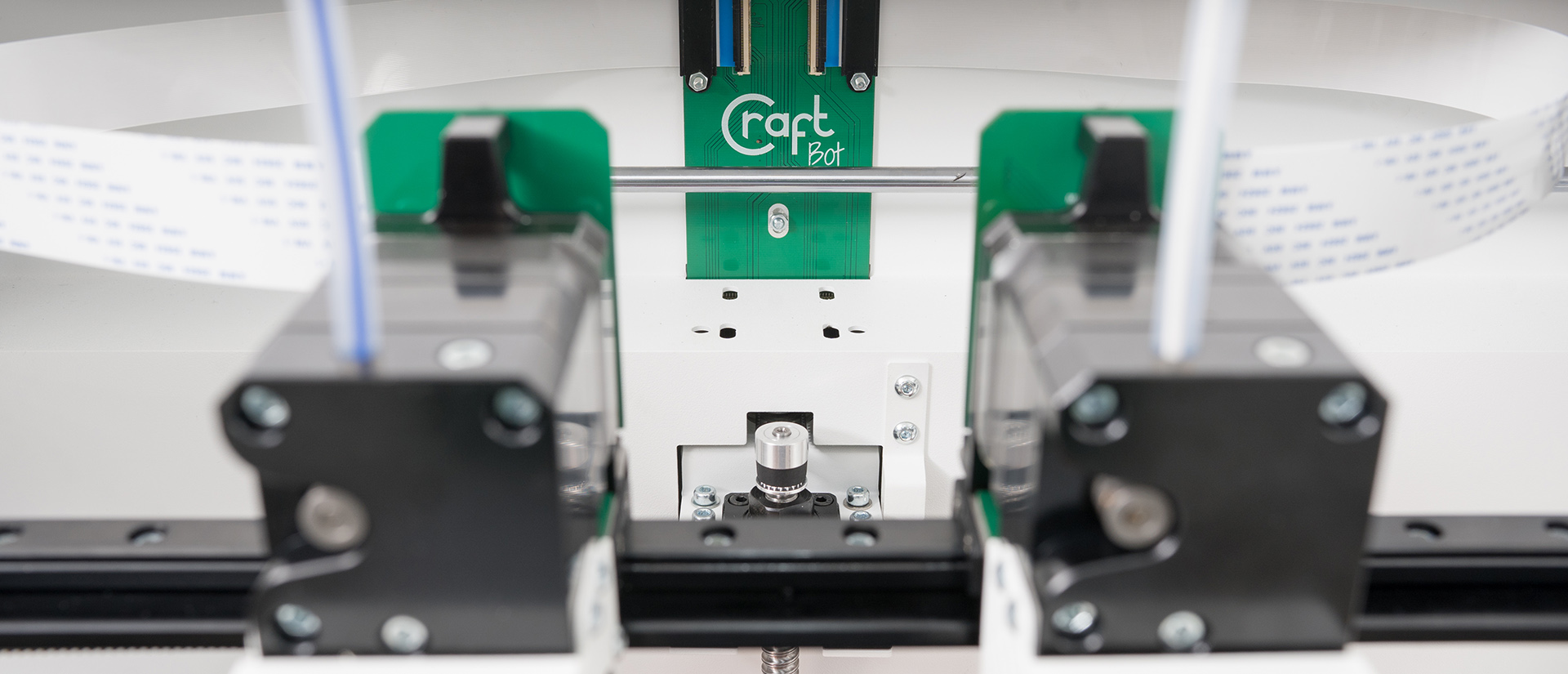

The IDEX Flow family members are intended to double the user’s performance, with dual extrusion capabilities and larger print volumes allowing for two simultaneous print jobs. IDEX functionality can be performed in mirror mode for doubling the output, in duplication mode for a higher volume production, and in multimaterial mode which allows users to 3D print objects using two different materials, bicolor items, or with PVA support.

Although they have two extruders, the CraftBot Flow IDEX and IDEX XL have the same print speed as the single extruder versions, with identical operating temperatures as well. Significantly, however, the CraftBot Flow IDEX is equipped with a build volume of 450 x 250 x 250 mm, whereas the IDEX XL goes even further, featuring a 450 x 250 x 500 mm build size – one of the largest IDEX ‘plug and play’ printers currently available in the marketplace.

Five year manufacturers warranty

Craft Unique’s experience in providing reliable and robust 3D printers through an interactive approach with clients has led to a 5 year warranty (5000 hours) on the new Flow Generation. With this type of warranty, end users can be reassured of the long term manufacturer’s support for its new generation of 3D printers.

CraftUnique will be presenting its new CraftBot Flow 3D printers at Formnext this year. You can find the company in Hall 12 Level 1 at booth A109. TO GET INTO THE FLOW, visit craftbot.com/flow.

For all of the latest 3D printer releases, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Looking for something new? Join 3D Printing Jobs now and advertise to attract new talent.

Featured image shows dual extruder on the CraftBot Flow IDEX 3D printer. Photo via CraftUnique.