CollPlant, an Israeli 3D bioprinting company and United Therapeutics Corporation, a Maryland-based biotechnology company, have commenced a license, development and commercialization agreement for the development of 3D bioprinted lung transplants.

Within this agreement, CollPlant will receive $5 million upfront, as well as regulatory and operational milestone payments of up to $15 million to manufacture and supply its bio-ink to United’s organ-manufacturing and transplantation subsidiary, Lung Biotechnology PBC.

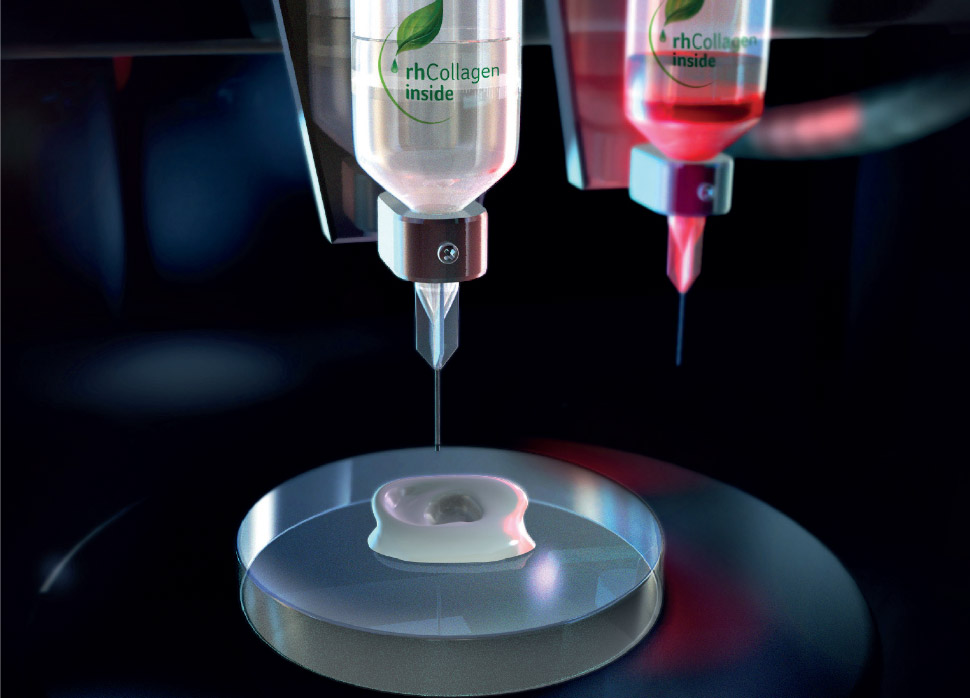

CollPlant’s proprietary recombinant human collagen (rhCollagen) is grown and harvested from tobacco plants engineered with five human genes. This purified collagen is used as a foundation when 3D bioprinting solid-organ scaffolds.

3D bioprinted lung transplants

According to CollPlant, collagen is a primary building block for the human body and has been a vital protein in the medical field as it is essential for tissue repair. Currently, most medical grade collagen derives from cadaveric or bovine (beef) or porcine sources, i.e., animal raw materials. Typically, collagen products are used for bone void fill or soft tissue augmentation procedures, treating chronic wounds, burns, or for cosmetic purposes.

CollPlant’s rhCollagen is produced through genetically engineered tobacco seedlings grown over 8 weeks. The tobacco leaves are then harvested, processed and refined until purified rhCollagen can be extracted. This process also deters disease or pathogen transmission – indirect contact infection, e.g. via needle prick injuries. Martine Rothblatt, Ph.D., Chairman and CEO of United Therapeutics stated:

“CollPlant’s extraordinary Israeli technology to transform the tobacco plant that is so associated with lung disease into a collagen-expressing plant that will be essential to the production of an unlimited number of transplantable lungs.”

Thus, this agreement will utilize rhCollagen and BioInk technology from CollPlant with the regenerative medicine and organ manufacturing experience of United Therapeutics to 3D printed lung transplants for patients in need.

Lung Biotechnology PBC invests in transplantable organ research

Earlier this year, Lung Biotechnology PBC contributed to the $9 million financing awarded to Indiana University School of Medicine (IUSM) to further their 3D bioprinting research for the development of transplantable organs. Prior to this, 3D Systems announced its plans to collaborate with Lung Biotechnology PBC to develop 3D bioprinting solutions.

Stay updated with the latest in additive manufacturing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows an animation showing precollagen fibers inside a single tobacco cell, to be extracted. Image via CollPlant.