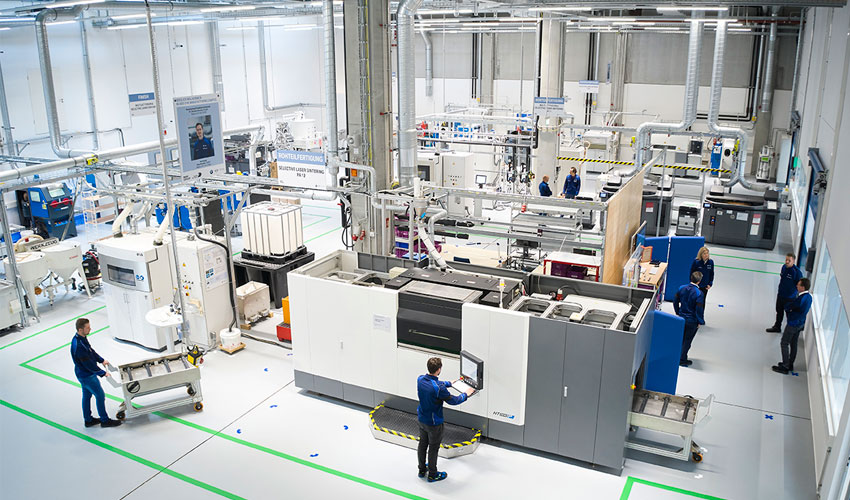

The BMW Group has opened a new €15 million additive manufacturing facility which is designed to “industrialize 3D printing,” and shorten production times across the company.

Based in Munich, the campus will bring BMW’s prototype production, series parts manufacturing, research into new 3D printing technologies, and training, together under one roof. The centre will also house around 50 percent of the automotive company’s global additive manufacturing (AM) capacity, comprising 50 industrial polymer and metal 3D printers. By centralising its 3D printing resources, BMW aims to accelerate its integration of AM, and to further automate its design and production processes.

“Our goal is to industrialize 3D printing methods more and more for automotive production, and to implement new automation concepts in the process chain,” said Daniel Schäfer, Senior Vice President for Production Integration and Pilot Plant at the BMW Group. “This will allow us to streamline component manufacturing for series production and speed up development. At the same time, we are collaborating to systematically integrate the technology and utilize it effectively.”

BMW’s commitment to 3D printing

Having first utilized 3D printing for prototype production in 1991, BMW has a long history of advancing AM, dating back nearly thirty years. The company still uses 3D printing for prototyping purposes at factories in Spartanburg (U.S.), Shenyang (China) and Rayong (Thailand), and it remains an important part of BMW’s business. Utilizing 3D printing in this way, has yielded a number of additive innovations over the years including a printable biodegradable concept car and a 3D printed S1000RR sports bike.

BMW has also entered a series of partnerships to develop its 3D printing technology, and to produce various car parts for its vehicles. Working with Belgian personalization software provider Twikit for instance, BMW has provided a mass customization service for its subsidiary car company MINI. Similarly, the Massachusetts Institute of Technology’s (MIT) Self-Assembly Lab collaborated with the car manufacturer to develop a rapid liquid printing technique for creating “next generation car” interiors.

More recently, the automotive company has accelerated its investment in 3D printing technology firms. BMW i Ventures for example, the venture capital arm of the BMW Group, invested in the Silicon Valley-based company Carbon in 2016. Using the company’s Digital Light Synthesis technology (DLS), BMW was able to more rapidly produce automotive components. This was followed by further investments in Desktop Metal, a start-up specialising in 3D printing metal components, and US printing platform Xometry, in 2017.

Following BMW’s previous €10m investment in its AM facilities, the company is now aiming to further integrate 3D printing into its production processes, in order to reduce waste and encourage automation.

“Over the last 30 years or so, the BMW Group has developed comprehensive skills, which we’ll continue to enhance on our new campus,” said Jens Ertel, Director of the Additive Manufacturing Campus. “We are working hard to mature additive manufacturing fully and benefit from it as far as possible throughout the product life-cycle, from the first vehicle concept through to production, aftersales and its use in classic vehicles.”

BMW’s new €15m additive manufacturing campus

BMW’s new facility will focus on optimizing 3D printing technology for “comprehensive use across the company.” By automating process chains that previously required large amounts of manual work within its own business, BMW aims to make 3D printing more economical and viable for use in the long-term. R&D will also be a major focus at the new campus, with the German government-backed Industrialisation and Digitisation of Additive Manufacturing for Automotive Series Production (IDAM) project also being developed there.

Working alongside 12 partners on the IDAM project, BMW is creating a production line that replicates the entire process chain, from the preparation of digital production, through to the manufacture and reworking of components. The replica will be configured for the requirements of series, individual and spare-part production, in order to gain the best understanding of how to optimize company’s the supply chain in future. Production targets for the enterprise confirm its status as a lighthouse project, with output expected to total at least 50,000 series components a year, including over 10,000 individual and spare parts.

Similarly BMW will work with 15 partners on the POLYLINE scheme, which focuses on the production of plastic parts, including digitally linking process steps, and the development of a consistent quality assurance methodology. The project’s findings could reduce manufacturing costs by up to 50 percent, while newly-integrated quality assurance methods are expected to increase the stability and sustainability of 3D printing in manufacturing.

In addition to optimizing BMW’s production process, the campus team will provide personal consultations and training courses for company associates, in order to get the maximum benefit from AM. “To roll these technologies out successfully, we need well-trained colleagues across the network who fully understand their advantages and features. To use them, designers will need to adopt a new way of thinking and an entirely new approach,” explained Ertel. “3D printing allows almost any shape to be produced, paving the way for new designs and functions. Nowadays, there are countless components that can only be manufactured additively.”

Other automotive companies in 3D printing

BMW has used 3D printing technology to produce a variety of car components in recent years, and many other automotive companies have done the same.

For example, additive manufacturing consultancy firm and Scalmalloy producer APWORKS 3D printed a titanium part for the latest Bugatti Chiron, the Chiron Pur Sport, in March 2020. The lightweight exhaust tailpipe was produced in titanium so that it featured very thin walls, making it more temperature resistant. The same month, sports car manufacturer Porsche, announced the development of its new 3D printed personalized bucket seats. While the seat was initially limited to 40 prototypes for use on European race tracks, the customer feedback is being used to develop a street-legal model for commercial release in 2021.

Triple Eight Race Engineering, an Australian motor racing team, is also using 3D printing technology, in this case from HP, to produce customized parts for its race cars. Working with EVOK3D, a 3D printing solutions provider, Triple Eight has been able to use HP Multi Jet Fusion (MJF) technology to 3D print a number of parts for its race car’s steering wheel.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows BMW’s new €15m additive manufacturing campus. Photo via The BMW Group.