PLA with 10% Hemp Fibers (from the bark of the cannabis plant)

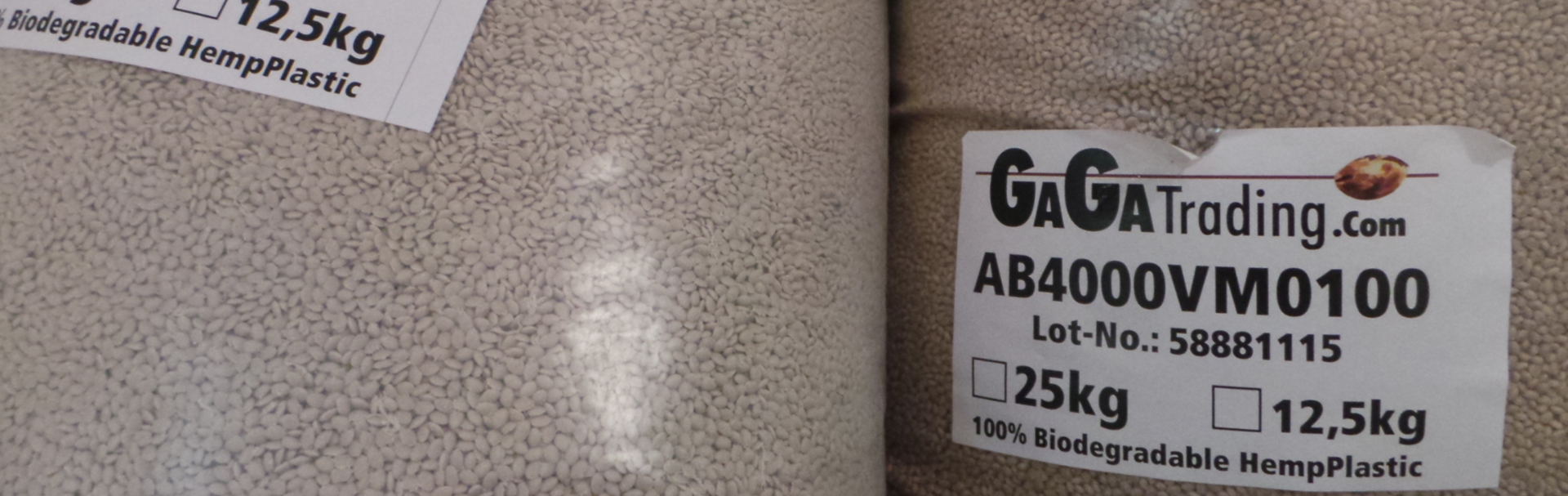

Old meets new; The Hemp fiber is one of the oldest and strongest natural fiber. PLA is a recently developed biodegradable plastic derived from renewable organic resources (corn starch or sugarcane). PLA is recyclable but can also be biological decomposed in composting plants. Bringing (compounding) these two materials together creates a strong but biodegradable and compostable new material. The Hemp fiber technique is based on the granulate products of Hemplyne.

The 3D4MAKERS PLA Hemp Filament has unique properties because it does not come into contact with water during the production process and is directly packaged in a vacuum packaging. These properties make the 3D4MAKERS PLA Hemp Filament particularly suitable for usage in FDM and FFF 3D printers. The material has an excellent adhesion between layers which results in great improvement of the impact resistance, strength, durability and the printing process.

For the best results we advise users of the 3D4MAKERS PLA Hemp Filament to use a different printing nozzle than the standard nozzle usually provided with 3D printers. A nozzle with a diameter of at least 0.5mm will give the best printing results.

The PLA Hemp Filament produced by 3D4MAKERS does not meet any European regulations concerning plastic materials and articles coming into contact with food.

Measurements & Tolerance

| Size | Diameter tolerance | Roundness |

|---|---|---|

| 1,75 mm Filament | +/- 0,08mm | 95% |

| 2,85 mm Filament | +/- 0,10mm | 95% |

| Moisture content | < 0,05% |

Safety information NOT AVAILABLE YET

3D4MAKERS assumes, based on the information provided by Hemplyne, that all raw materials used in their product are in accordance with the European regulations on RohS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

Legally Obliged Information NOT AVALABLE YET

3D4MAKERS assumes, based on the information provided by Hemplyne, that all raw materials used in their product are in accordance with the European regulations on RohS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals

Environmental information

Plastic waste can damage the environment. 3D misprints must be separated with plastic waste together with the Filament reel. 3D4MAKERS is developing a return system for 3D misprints and the Filament reel.

Together we can protect the environment!

Now online available at wwww.3d4makers.com

Hemplyne available via www.hemplyne.com