Additive manufacturing VC firm AM Ventures is backing the imminent expansion of German 3D printing start-up MetShape by providing it with seed financing.

Developed over the last two years, MetShape’s Lithography Metal Manufacturing (LMM) process allows users to flexibly 3D print parts with complex geometries at scale, while potentially bringing them substantial cost savings. Using its newly-raised funding, the firm now intends to acquire equipment, hire staff and ramp up its sales and marketing operations, as it prepares to bring its technology to market.

“With the further development of the company, we are increasing customer benefits to the extent that we are evolving from an LMM pioneer to a competent partner,” said Dr. Andreas Baum, CEO of MetShape. “By expanding its competence profile, MetShape offers its customers not only comprehensive technology consulting, but also the rapid realization of economic advantages with the highest flexibility.”

“With our holistic approach and know-how of the entire LMM process chain, we provide our customers the highest flexibility in developing and manufacturing their applications.”

Embracing ‘indirect’ 3D printing

Based in the South Western city of Pforzheim, MetShape’s business revolves around its proprietary LMM process, through which it offers consultation and on-demand production services. Due to the emerging nature of its technology, much of the firm’s current offering takes on an advisory form, and its services include material qualification, design optimization and developing use-specific parameter sets.

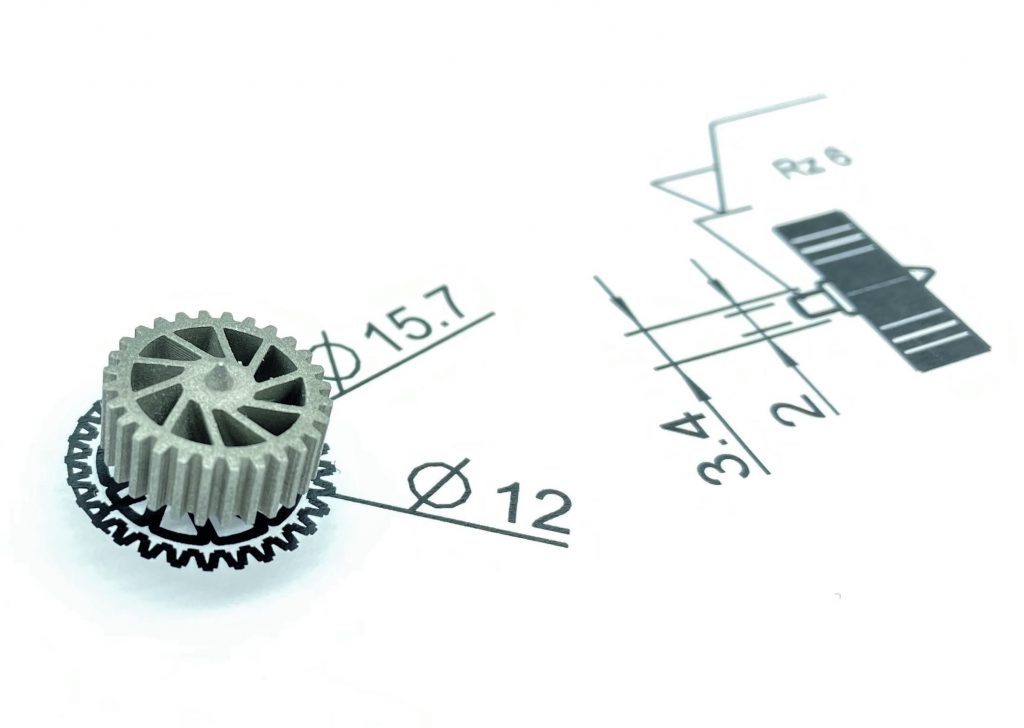

In effect, the company’s ‘LMM’ technology describes an indirect two-step process, in which binder-infused metal feedstocks are photopolymerized into cross-linked parts, before being sintered to achieve thermal debinding. According to MetShape, its approach is capable of yielding high-resolution parts with complex overhangs, that are similar in quality to their metal injection molded (MIM) equivalents.

Since being spun out of nearby Pforzheim University back in 2019, the company has used the initial backing gained from the state of Baden-Württemberg, to invest in its portfolio and establish specific applications for it. Moving forwards, the firm now says that it aims to work with Incus GmbH and Pforzheim University to continue developing its process, as a means of remaining “at the cutting edge.”

In terms of its newly-raised finance, MetShape has earmarked it for a significant recruitment drive, as well as a further expansion of its offering. The company’s larger marketing team should also open further commercial opportunities for the deployment of its technology, and it’s actively seeking “cooperation projects,” in which it can test its process’ potential.

For AM Ventures’ Johann Oberhofer, two-step sinter-based 3D printing technologies are set to become “increasingly important for the production of larger quantities of metal components,” thus he considers the funding awarded to Baum and his team, to be an investment in a process with significant high-throughput applications.

“The key to mastering indirect AM processes is to control the oven-based sintering processes after the green part has been 3D printed,” added Johann Oberhofer, Managing Partner of AM Ventures. “We are convinced that the team around Dr. Andreas Baum combines the necessary competences and has extensive know-how for the development and serial production of high-quality applications.”

Backing AM’s emerging start-ups

Set up by EOS founder Hans Langer and his family in 2013, AM Ventures is a VC firm committed to finding and investing in 3D printing’s most promising start-ups. With this in mind, the company launched a dedicated €100 million VC fund in March 2021, which Dr. Langer hailed as allowing the firm to “take its business to the next level.”

Even prior to its latest funding initiative, AM Ventures has established a strong track record when it comes to helping new 3D printing firms fulfill their potential. In September 2020, for instance, AM Ventures contributed to 3YOURMIND’s $5.5 million funding round, which has since funded its aerospace and automotive expansion.

In the past, the company has also backed post-processing specialist DyeMansion, by supporting its $14 million fundraising during August 2020. Using this funding, the firm has been able to accelerate its transition to a ‘fully-digital manufacturing workflow’ by increasing automation and integration across its business.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a high-precision gear 3D printed using MetShape’s LMM technology. Image via AM Ventures.