London-based 3D printing service provider Ai Build, has introduced a new version of its AiMaker. In this update, the system has been upgraded to work a larger build chamber and it features enhanced 3D vision capabilities.

The machine was recently showcased at the Future Lab, Goodwood Festival of Speed 2019 (FOS) in the UK. The Future Lab is a dedicated area at the FOS where each year exhibits are organized around a theme from the future of technology. Smart cities, future of flight and robots and AI were the prevalent themes of this year’s edition.

Automating manufacturing

The goal of Ai Build is to provide a fully automated 3D printer that can be accessed and controlled from anywhere in the world. It focuses on the fabrication of large scale structures, which it provides through its “factory as a service” offering.

Ai Build’s 3D printing package includes the AiMaker, AiCell, and AiSync. AiMaker is a ‘smart’ extruder that can be attached to a robotic arm, AiCell is a heated chamber which keeps the temperature of the build area consistent, and Ai Sync is for managing the extruder and collecting data points for feedback.

In the newest AiMaker upgrade, a larger AiCell (AiCell Medium) has been added to the system, accommoding a build volume of 120cm x 80cm x 140cm (XYZ). To enhance the capabilities of its system the robot-arm operated machine has also integrated a 3D vision-based quality control system, which can adjust parameters in real time.

“At Ai Build,” comments company Co-Founder and Creative Director Michail Desyllas, “we are driven by quality and perfection. Our solutions aim to change how manufacturing is performed, with automation and efficiency as key drivers.”

“AiSync and AiMaker are built to give flexibility and support to creative manufacturers and engineers to express their designs fluidly and effortlessly.”

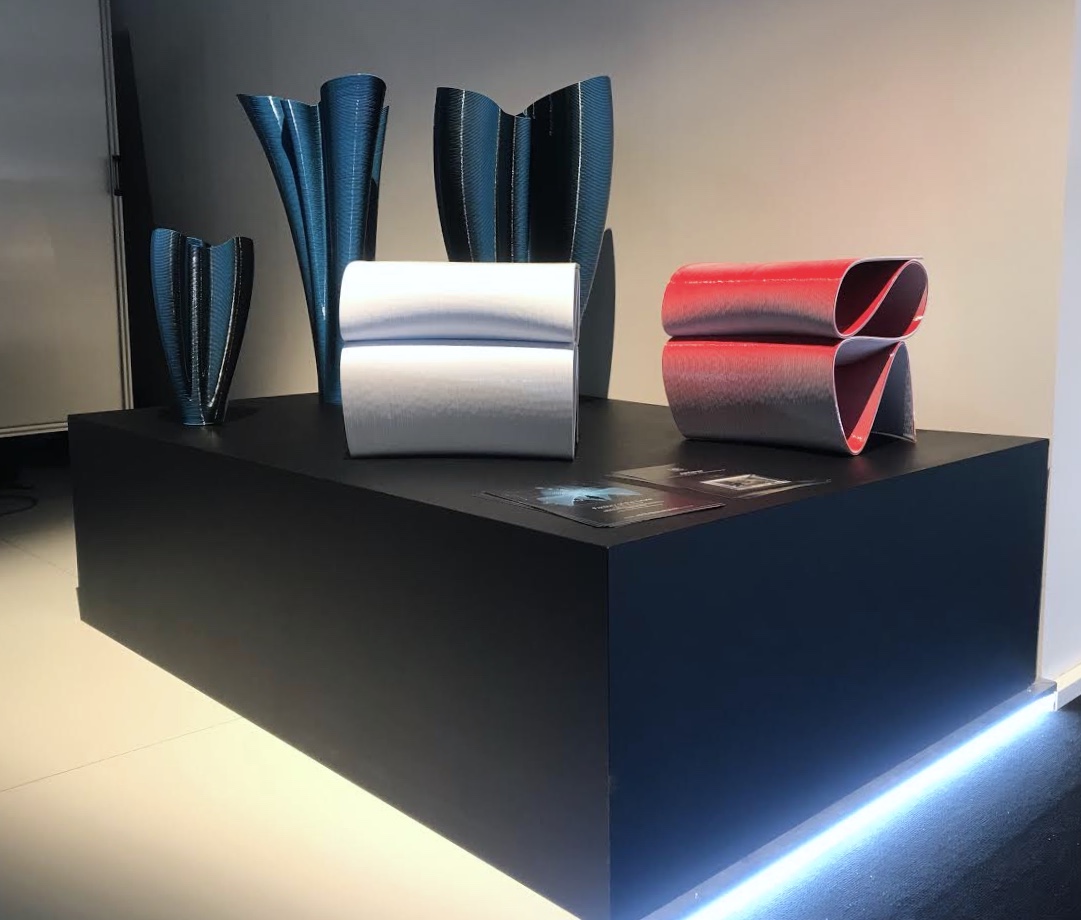

At the Future Lab of Goodwood Festival of Speed 2019, visitors were treated to a live furniture 3D printing show by Ai Build. Using the latest version of the AiMaker and AiCell, Ai Build 3D printed creative furniture pieces like stools and vases.

Creating smart

Since its introduction, the Ai Build package has been used by various designers including Assa Ashuach, Zaha Hadid Architects, and Kohn Pedersen Fox Associates (KPF), one of the largest architectural firms in New York City and designer of the London skyscraper, The Scalpel.

Cobus Bothma, Director of Applied Research at KPF, said, “KPF has been using the AiMaker to test the possibilities of robotic fabrication in architectural design. Collaborating with Ai Build enabled us to explore and concentrate on its capabilities, rather than spend that time programming robotics ourselves.”

“Using an integrated software and hardware system allows us to focus on design and toolpath exploration, and rely on the software to automate the fabrication process.”

Ai Build’s 3D printer is provided to customers through an annual subscription program, with a choice between Basic and Professional Combo. The latest version of Ai Maker is now available to buy at the Ai Build’s website.

To learn more about 3D printing subscribe to our 3D printing newsletter and join us on Facebook and Twitter.

For jobs in the industry visit our 3D Printing Jobs page.

Featured image shows Ai Maker inside an AiCell at the Future Lab. Image via Ai Build.