Award-winning 3D printer manufacturer Aerosint and precision laser micromachining specialist LASEA, are collaborating to build an additive manufacturing system with in situ laser ablation.

The two-year project has a total budget of almost €1 million and is supported by a research grant from the regional government of Wallonia, Belgium. It aims to leverage the geometrical freedom of LPBF with the fine details and surface finish quality possible from laser ablation.

“We always seek synergies with other companies in our market niches and we are convinced that the collaboration with Aerosint will be pleasant and fruitful,” said Axel Kupisiewicz, Founder and CEO of LASEA.”We are seeing attraction around laser additive manufacturing.

“Thanks to the collaboration with Aerosint and its innovative powder management system, we are convinced that their approach combined with LASEA knowhow on ultrafast laser micromachining will lead us to promising results.”

Laser ablation and LPBF

Since 1999, LASEA has manufactured workstations and custom machines for marking, engraving, cutting, drilling, texturing, thin film removal, welding, and micromachining. Kupisiewicz added, “We have been developing subtractive laser systems for many years based on ablation with ultrashort pulse lasers, a technology in great expansion and for which the advantages have been demonstrated over the past decades.”

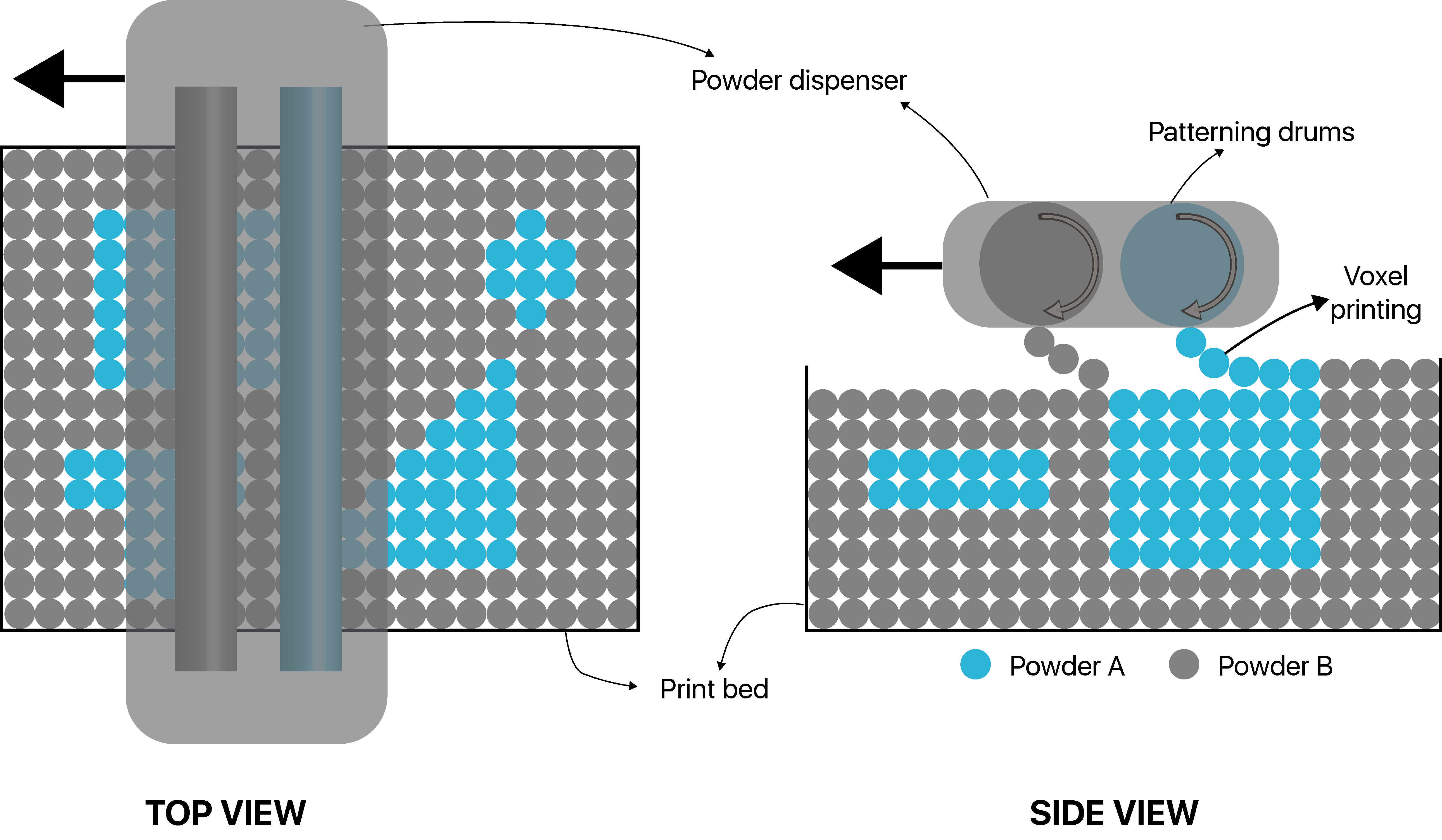

Conversely, Aerosint was established to reinvent the technical approach in powder fusion-based additive manufacturing, thus it created multi-material powder recoater technology. The project will facilitate the two companies’ development of a hybrid process aimed at applications in the traditional markets of LASEA. This includes the watch & jewelry, electronics, and medical devices sectors.

As stated by the partners, these industries require parts with high surface quality and dimensional tolerances. Therefore, LASEA will investigate the powder melting and ablation process conditions in a new system while Aerosint will focus on powder handling and deposition control of the metal powders.

Aerosint and LASEA

Aerosint’s powder recoater is being leveraged in this project due to its material flexibility, and the ability to produce multi-metal components. LASEA also sees this project as a possible entrance into the OEM space of additive manufacturing systems. If the hybrid process is successful, the system will be made commercially viable.

“LASEA is a company we look up to in the Liège area,” explained Matthias Hick, Co-founder, and CTO of Aerosint. “They have been extremely successful in the last couple of years showing double-digit growth year after year.”

“Working on such an innovative process with LASEA is in line with our strategy to demonstrate how selective powder deposition can unlock a range of very unique use cases in AM and beyond. We look forward to supporting LASEA in this project

which we are convinced will yield very interesting results.”

For the latest additive manufacturing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a micromachining system from LASEA. Photo via LASEA.