The business model is the same as many other 3D printer manufacturers: a company that produces industrial machinery decides to invest into the development of a 3D printer in order to address the demand for internal parts and open up new possible business areas. 3DPRN, a company based in Teramo, has done this and introduced a novel approach that combines additive and subtractive technologies in an very serious, tough and (relatively) low-cost system.

Unlike many other 3D printers on the market, 3PRN’s machines have a completely independent Z axis, which enable either printing of objects in a sequence or transformation into a CNC milling arm for automated dimensional correction of the 3D printed objects, which is basically what many industrial systems already strive to do.

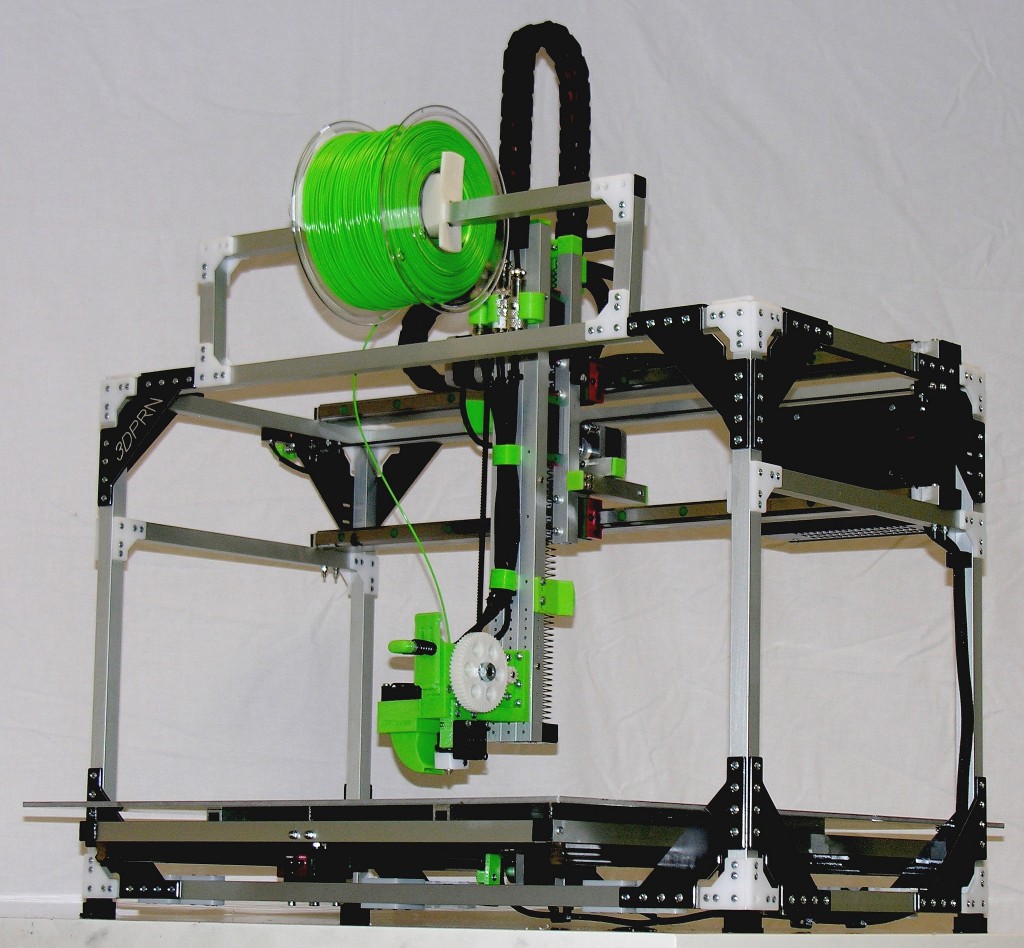

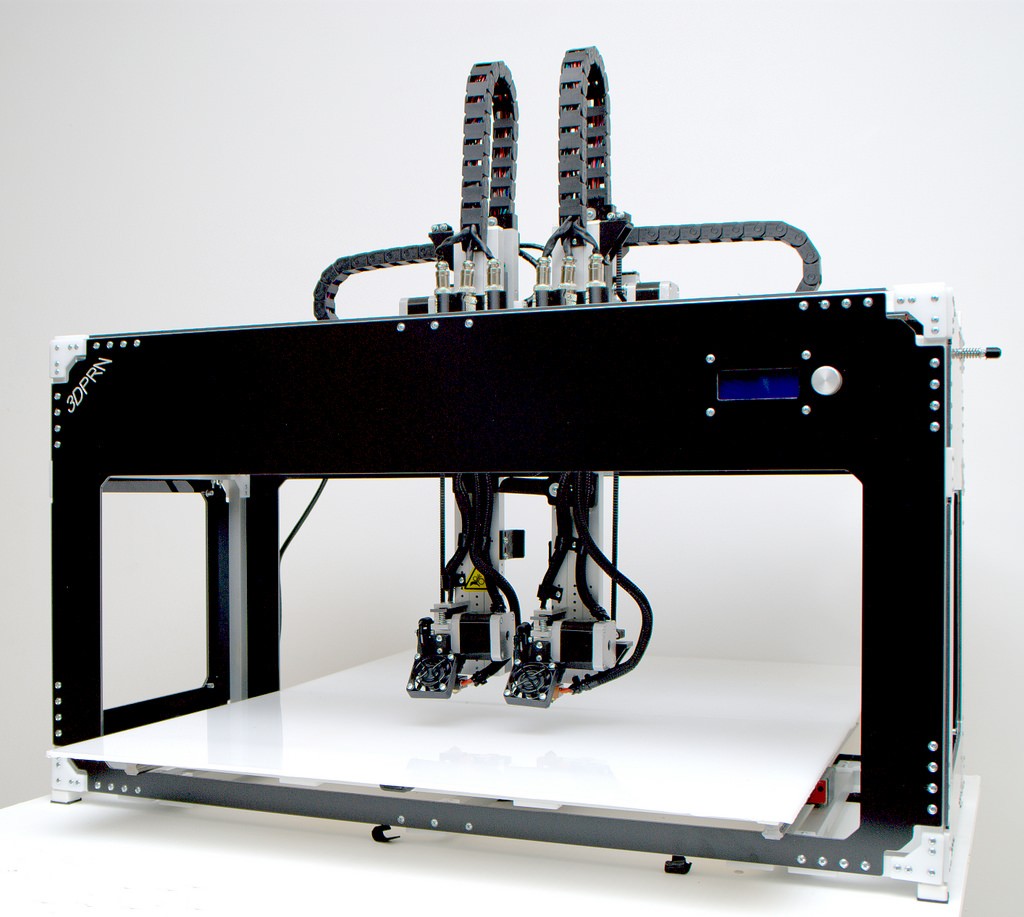

3DPRN offers three different ranges of machines for Maker-, professional- and industrial-level 3D printing. They are defined by the 3DPRN-BASIC LX, 3DPRN LAB and 3DPRN MONSTER brands. This may be a rather standard subdivision of business segments; however, 3DPRN’s 3D printers stand out in that they integrate all-metal profiles and high-performance, professional linear guides.

Perhaps even more significantly, all the 3D printers can be expanded (the printing volume ranges from 200x200x320 mm to 650x670x500 mm) and upgraded to the top model in the segment, or to the latest model, through the purchase of a specific kit. All models have a dual mode (Bowden or RepRap-based) extruder, supporting both 1.75 and 3 mm size filaments.

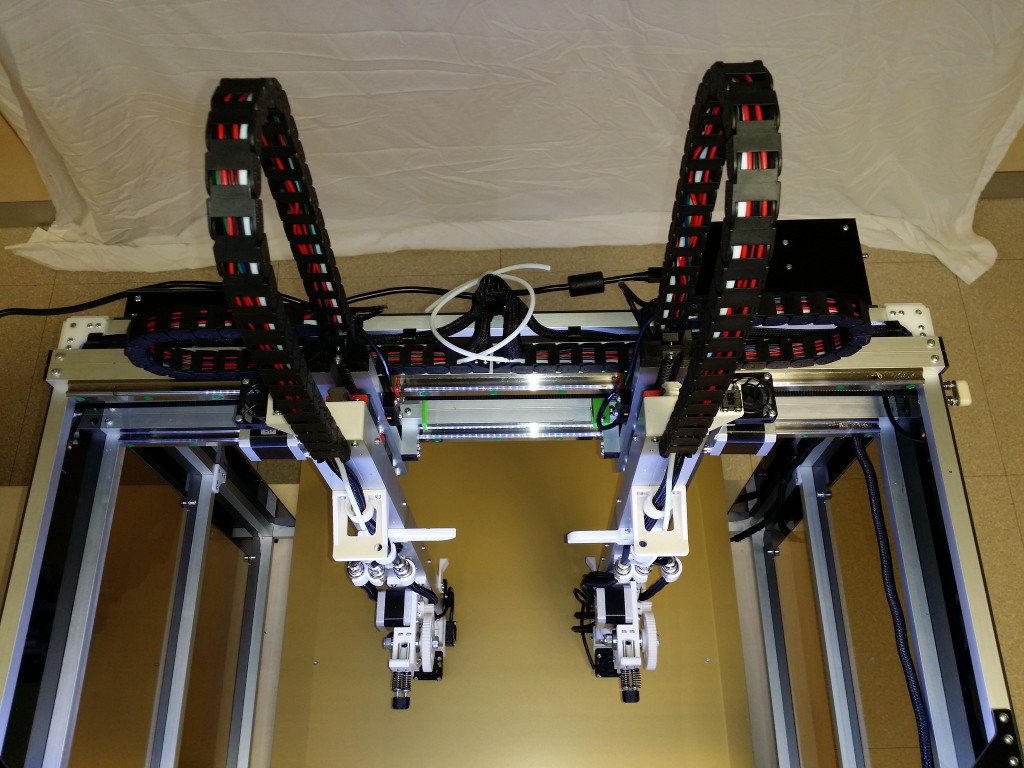

The LAB model can be turned into a tough CNC mill, while the MONSTER model can actually 3D print and mill at the same time, through its two independent arms. In fact, the two heads could also be used to 3D print with two different materials: while one head is not being used, it simply parks itself. In the future, the milling arm might even be able to move on more axes, in order to better reach all sections of the 3D printed components.

This is a glimpse into the future of FFF 3D printing and it kind of makes me smile when people think that fused filament 3D printing is going to be replaced by another technology. Unfortunately – or fortunately, depending upon the point of view – all-encompassing 3D printing technology seems like a very distant mirage.