3D Systems, has announced a strategic partnership with GF Machining Solutions, a division of Switzerland-based manufacturing company Georg Fischer, to deliver a new concept in factory automation that will improve metal parts production.

The companies intend to develop new software for material handling systems, milling equipment and other subtractive and additive manufacturing methods to allow a seamless workflow within smart factories.

“The 3D Systems and GF Machining Solutions partnership brings together two customer-centric innovators to redefine manufacturing and create the factory of the future,” said Vyomesh Joshi, President and CEO of 3D Systems.

“As industry leaders, both companies share the same vision for transforming manufacturing.”

“We are looking forward to delivering integrated technology solutions to provide our customers with significant competitive advantage through reduced production time, faster time to part, and overall lower total cost of operation.”

Redefining the “factory of the future”

With a presence in over 50 countries, GF Machining Solutions has developed advanced automation and post-processing technologies, such as its AgieCharmilles LASER P 400 U system, a five-axis texturing machine for precision parts. This system uses two short pulsed lasers directed from an interior design studio to accurately engrave small metal components.

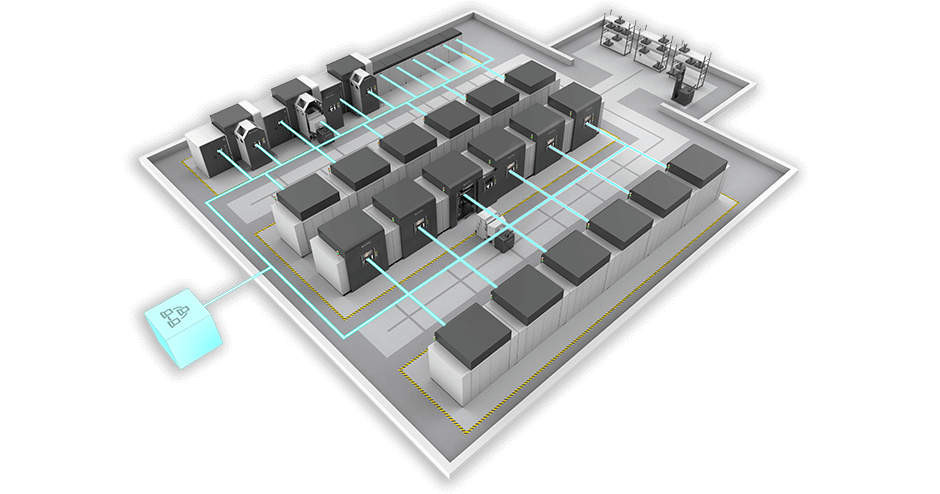

This partnership will work to develop a new concept in factory automation with both subtractive and additive manufacturing processes, enabling manufacturers to more efficiently produce complex metal parts within tight tolerances. The integrated system is also said to foster new designs, business models, and markets.

Software will be created for manufacturing processes including enhanced part design, materials and automated material handling, post-processing procedures, and electrical discharge machining (EDM) – a subtractive manufacturing process that uses the erosive effect of electrical bursts to shape metals.

3D printers, as well as milling equipment, will also be integrated into the automated factory system.

“We are excited about this new partnership of two industrial leaders”, said Yves Serra, CEO of Georg Fischer. “With the combined experience and expertise of 3D Systems and GF Machining Solutions, we are well positioned to bring to our customers new manufacturing solutions based on 3D printing.”

The first automated system produced from this partnership will be debuted at the International Manufacturing Technology Show (IMTS) 2018 from September 10-15, in Chicago, Illinois.

Additive manufacturing and smart factories

Deriving from Industry 4.0, smart factories (factories of the future), where machines can operate with minimal human input, have demonstrated new methods of increasing production.

From Concept Laser’s Automated Guided Vehicles (AGV) designed to transport parts on a factory floor to Voodoo Manufacturing’s robot-operated production line, additive manufacturing technologies, including CAD design software, are enabling a non-manual factory environment, increasing an organization’s productivity and output.

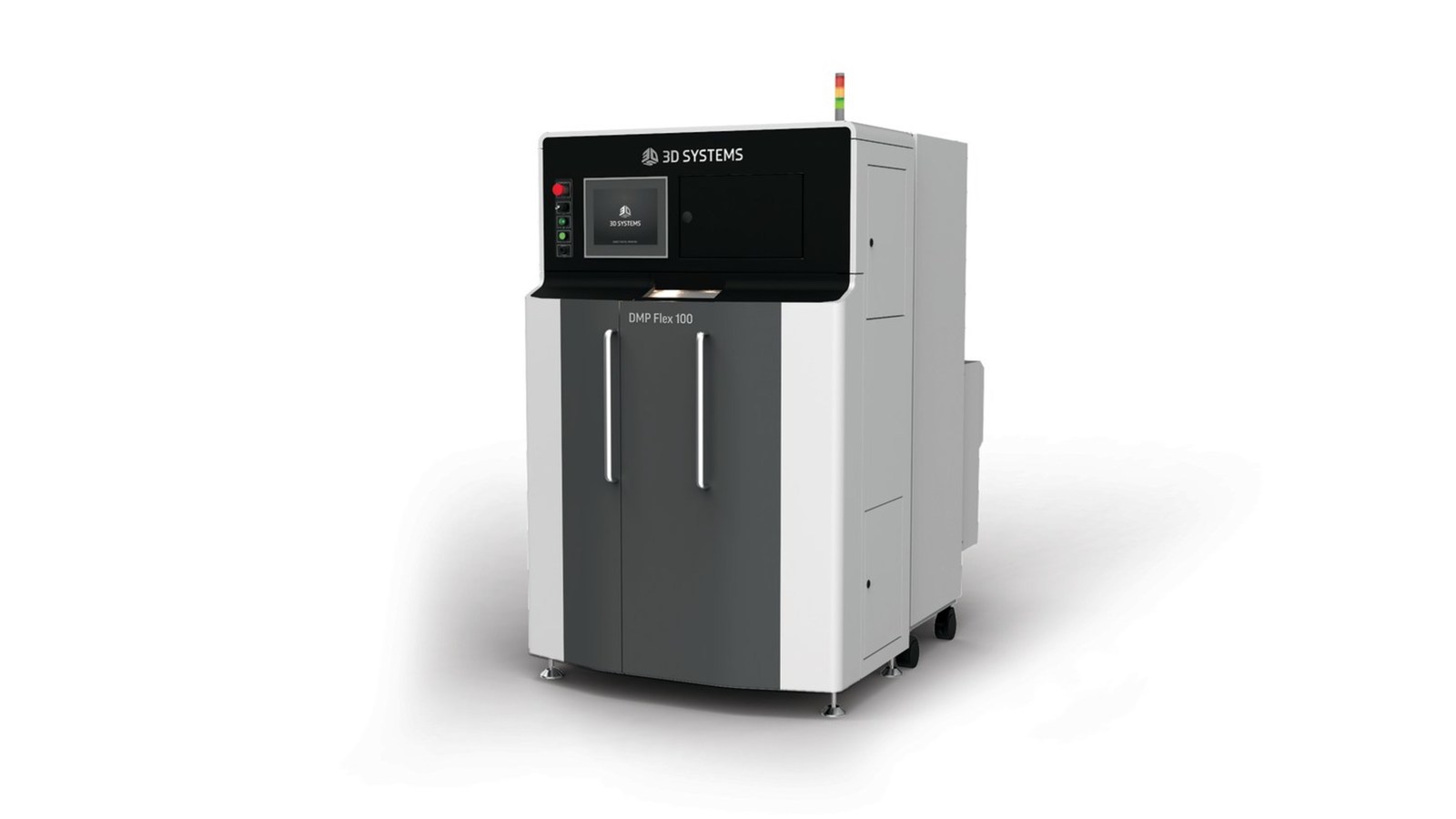

Last year, 3D Systems introduced the DMP 8500 Factory Solution, a new factory floor additive metal production platform based on its Direct Metal Printing (DMP) technology. This system has the capability to print parts up to 500 mm x 500 mm x 500 mm in volume and has printer modules designed for 24/7 part production.

Catch up with the latest news in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Seeking a new position in the additive manufacturing industry? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows DMP 8500 Factory Solution. Image via 3D Systems.