In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across the additive manufacturing world.

Read on for the latest 3D printing news announced by 3D Systems, Arfona, Prodways Group, Ultimaker, MakerOS, M.Holland, Renishaw, and more.

JEC World, Hannover Messe, and MACH postponed

JEC World 2020, the international trade show for composite materials, is postponed due to concerns about the Coronavirus. The Paris trade show has visitors from more than 112 countries, bringing together experts from the scientific and academic world, associations, and the media. Given the current circumstances, the JEC World team consulted its stakeholders and decided to hold the event between May 12-14, 2020, instead of March 3-5.

For similar reasons, Deutsche Messe, a German trade fair operator, has announced it will postpone its Hannover Messe 2020 event. Therefore, instead of April 20-24, 2020, the trade fair will be held between July 13-17, 2020.

MACH 2020, a UK-based manufacturing exhibition, is also rescheduled. The organizers of the show, the Manufacturing Technologies Association (MTA), will delay the show until next year. The exhibition will now take place at the Birmingham NEC, between January 25-28 2021, instead of April 20-24, 2020.

Additive Manufacturing advances for digital dentistry

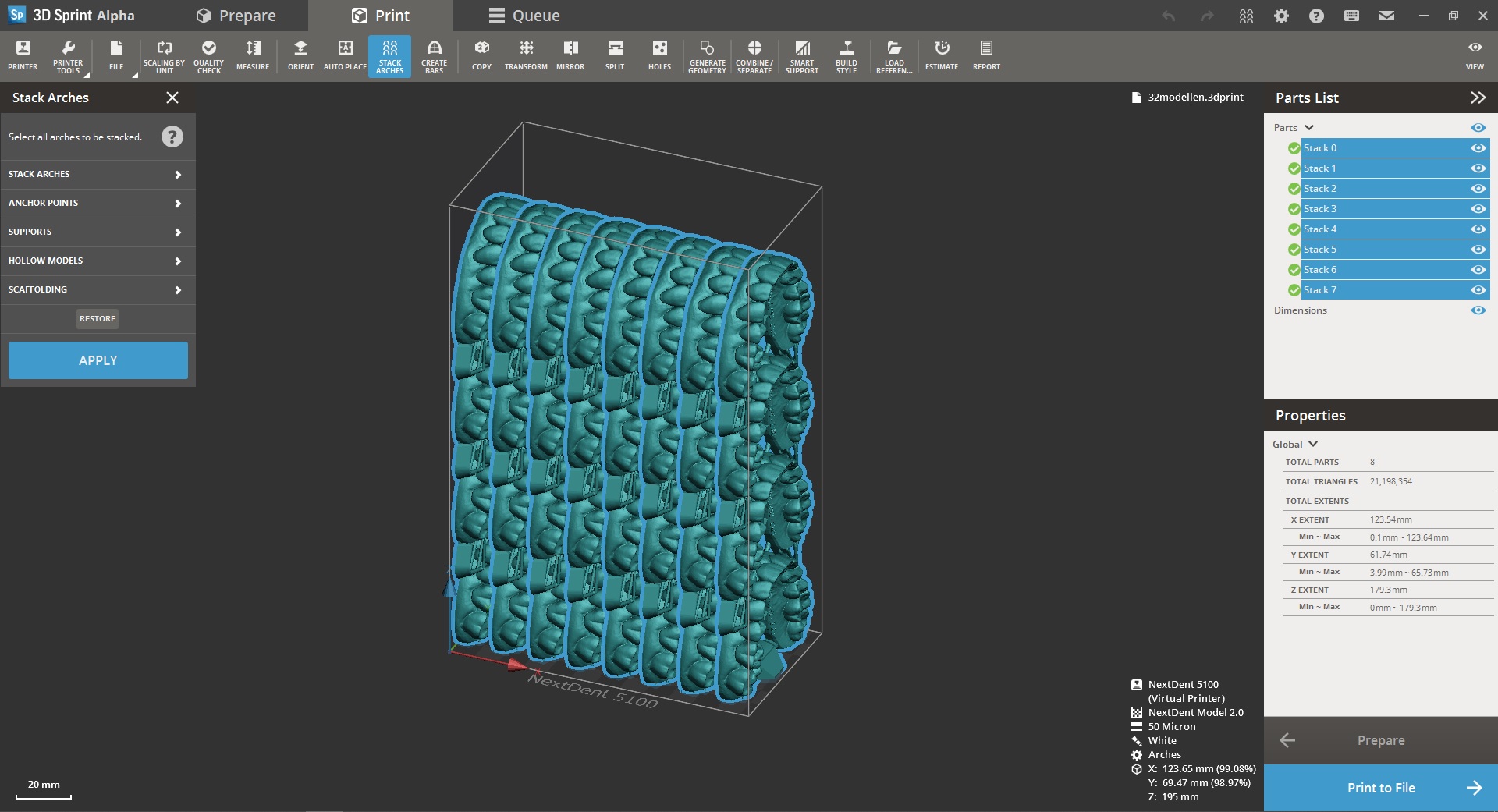

3D Systems has released a new feature for its 3D Sprint software. The new feature allows dental labs to stack orthodontic models vertically automatically. With auto-stacking utilization of the build chamber is increased, which increases the efficiency of the NextDent 5100 3D printer, particularly when used in conjunction with the company’s NextDent Model 2.0 material. With this update, dentists can 3D print 30 orthodontic models in one print job, allowing up to 120 models per day, says 3D Systems.

Brooklyn-based dental technology startup Arfona has announced a new filament. FILAdent PMMA is optimized to print with a denture base resin from Valplast and can be used with the Arfona r.Pod 3D printer’s dual-extrusion capabilities.

Arfona has also announced relocation to New York. The new AM hub will provide Valplast’s additive manufacturing services to dental labs, and take models and intraoral scans from dental laboratories.

French 3D printer manufacturer, Prodways Group has introduced a Clear Aligners Manufacturing Ecosystem to automatize the steps in aligner serial manufacturing. The end-to-end ecosystem integrates 3D scanning, data preparation, treatment design, 3D printing, thermoforming, laser marking, and trimming. Prodways works with companies from in digital dentistry, including 3Shape, Full Contour, Imes-Icore, and Dreve. With the new development, Prodways promises a smooth manufacturing process and daily production capacity of 1200 aligners, as well as lower cost-per-part and certainty of results.

Prodways is also working with the automotive manufacturing company, Continental Engineering Services, to 3D print tools and prototypes. As owners of a Prodways ProMaker P4500 HT SLS system, the company now 3D prints high-temperature resistant parts itself, instead of outsourcing the production. Kevin Veysseix, from Continental Engineering Services, said, “Now it takes only 3 days to go from the CAD design to the physical part ready to be tested, and this shortens dramatically our time to market by a factor of 3 or 4.”

In the future, Continental plans to 3D print trays for PCBs, classification systems, and packing units.

3D printing for automotive, consumer goods and end-use applications

CUPRA, the “Cup Racing” car brand of SEAT, is working with HP to implement 3D printing into its new model, the Leon Competición. CUPRA is using HP’s Multi Jet Fusion 5200 technology to design, produce, and test multiple parts of the racing touring car. These components include the steering wheel’s center control module, the bonnet air vents, door mirrors, and the brake and water cooling inlets.

3D printing is increasingly allowing enterprises to bring innovation to the market rapidly. UK-based cable cleat manufacturer, Ellis, has developed a twist foot fixing mechanism for its Emperor and Vulcan+ cable cleats to reduce installation time and cost. The new cleats are designed for installations using a cable channel and a ladder with inverted rungs. The North Yorkshire based company deployed its Stratasys Objet 24 and Objet 30 printers, with production taking place over a couple of days.

Stephen Walton, Technical Director of Ellis, said, “Taking a product from an idea in a brainstorm to a fully functional, production-ready prototype in less than a fortnight goes to show what is possible with today’s technology.”

German eyewear brand Mykita is working with optics manufacturer Leica, to craft a collection of sunglasses using 3D printing technology. The hybrid frames of the debut collection combine handcrafted stainless steel with Mykita’s polyamide material, Mylon.

3D printing software news

Ultimaker, a desktop 3D printer provider based in the Netherlands, has launched a web-based marketplace to give users access to plugins for industry-standard software platforms. The company has also released new features in its Cura 4.5 software, such as brim distance and skin edge support.

Dick Moerkens, CTO at Ultimaker said, “Where one user is more eager to manually tweak and test every setting available, others want to fully integrate 3D printing into existing workflows. I am proud of our open approach and agile development strategy, which allows us to fully streamline and simplify the 3D printing workflow now and in the future.”

MakerOS, a web-based software platform for 3D printing companies, has announced the launch of its online quoting feature. The Public Autoquoter is integrated with other project management features, such as advanced pricing modifiers and an abandoned quote recovery tool.

Mike Moceri, CEO and Founder of MakerOS, said, “Our Autoquoter is responsive to the customer’s needs. You can steer clients down the appropriate path based on the needs of their project. Every element is customizable for the business owner. There’s less friction, projects are completed faster, and everyone wins.”

Renishaw’s AM400 machine will be used by Mississippi State University Center for Advanced Vehicular Systems (CAVS) to install Sigma Labs’ PrintRite3D platform. A Santa Fe-based AM software developer, Sigma Labs has been awarded a contract by CAVS to test and demonstrate PrintRite3D’s interoperability potential.

Mark K. Ruport, Executive Chairman of Sigma Labs, said, “They have agreed to act as a testbed for new product improvements to PrintRite3D, uniquely allowing us a real-world feedback loop to continuously improve our technology suite. I look forward to working with the entire team at CAVS to bring a new level of quality assurance to both their partners and the additive manufacturing industry as a whole.”

New additive manufacturing partnerships, reseller, and distribution news

Sintratec, a Swiss SLS 3D printer manufacturer, has announced a new partnership with Bender AM, a Dutch distributor, to expand in Western Europe. With Sintratec’s S2 system, Bender AM will now provide a complete portfolio of 3D printers and related materials.

M.Holland Company, an Illinois-based thermoplastic resin supplier, will distribute Ultrafuse 316L, stainless-steel composite filament from BASF 3D Printing Solutions.

Haleyanne Freedman, Market Manager at M. Holland, said, “This metal-polymer composite filament is a groundbreaking and industry-changing product that is also cost-effective. Our clients can leverage this distinct material to complement existing plastic injection molding opportunities and a wide array of other applications.”

In Switzerland, ALSO Holding, a technology provider company, will also distribute materials from BASF 3D Printing Solutions, specifically the Ultrasint TPU01 thermoplastic. This material is suitable for manufacturing tough, abrasion-resistant, and flexible elastic parts.

Gustavo Möller-Hergt, CEO of ALSO Holding, said, “With this BASF material we are expanding the capabilities of our HP Jet Fusion 3D printing portfolio to include an extremely high-quality product that can be used in the production of a wide range of goods and components – from sports shoes to automobiles.”

Elsewhere, Altem Technologies, an Indian 3D printer distributor company, has won this year’s Platinum Partner Award of Dassault Systèmes for its efficiency. Sharath Chandra, Vice President of software sales at Altem Technologies, said, “It is a proud moment for Altem to be recognized as the Platinum Partner and this would not have been possible without the continuous support of our customers in giving us business. I also congratulate my entire team at Altem for this success. ”

Facility and installation news

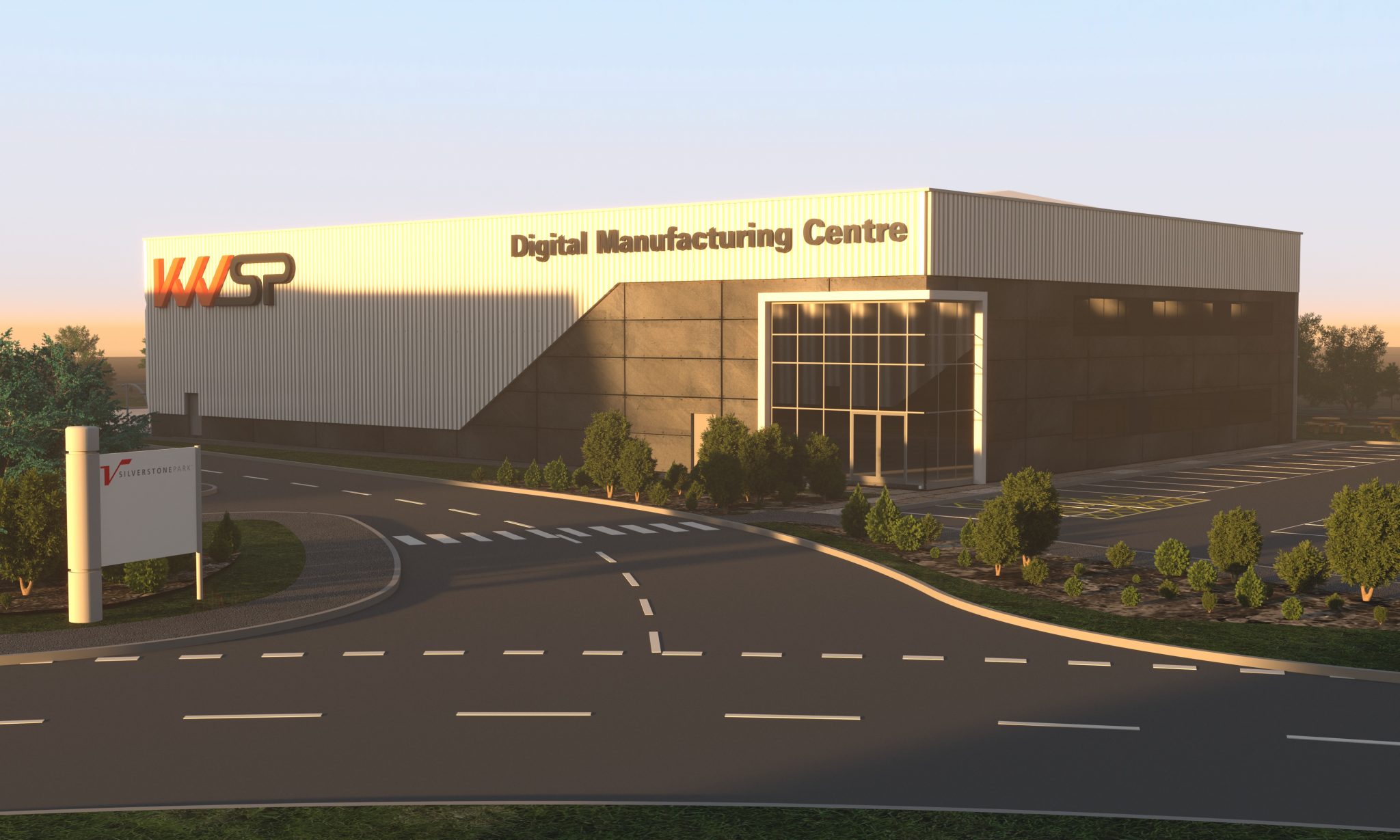

KWSP, a high-performance engineering company, has purchased the NEO800 3D printer from British 3D printer manufacturer RPS, to place in its new Digital Manufacturing Centre (DMC). The DMC will be used as an additive manufacturing hub and innovation center, with capabilities including design, engineering, manufacturing, inspection, and post-processing.

Kieron Salter, Director of KWSP, stated, “With the launch of the KWSP’s specialist Digital Manufacturing Centre in autumn 2020, we look forward to bringing this capability together with metallic additive manufacturing processes and of course our existing established FDM to a wide range of customers.”

The UK-based Manufacturing Technology Center has installed a TruPrint 3000 metal 3D printing system from TRUMPF to showcase the potential of laser powder bed fusion to its customers. The MTC aims to enable its clients to compare the different metal AM technologies and discover which process suits their needs. After investing in a Fortus 450mc in January, the TruPrint 3000 is the latest 3D printer added to the MTC’s National Centre for Additive Manufacturing (NCAM).

3D printing education and scholarship news

Renishaw, a British engineering firm, has renewed its 3D printer school loan project. Last year, 21 primary schools and nine secondary schools in South Wales were given a 3D printer for a three-month period. Renishaw also provided training and a guiding booklet for teachers.

Simon Biggs, Education Outreach Officer at Renishaw, said, “We’ve had 100 percent fantastic feedback from all of the schools who took part last year, with many asking to loan a printer again. Without the loan scheme, many of the schools taking part would not be able to access this type of equipment and therefore couldn’t use it in day-to-day teaching.”

One teacher, whose school borrowed a 3D printer, said, “The children absolutely loved using the printers. It has sparked an interest in some of the children to work with 3D printers in the future.”

Another educator commented, “The children were able to make special Mother’s Day gifts, which had a positive impact on them and they were extremely proud of what they were creating.”

Elsewhere, the Additive Manufacturing Users Group (AMUG) has announced the recipients of its scholarships. Katherine Schneidau, a mechanical engineering student at the University of Louisville, won the Guy E. Bourdeau Scholarship. The Randy Stevens Scholarship was given to Chris Kaminsky, Lakeshore Fab Lab Manager at the Muskegon Community College.

Brett Charlton, Chair of the AMUG Scholarship Committee, said, “I’m so excited to announce that Ms. Schneidau and Mr. Kaminsky have accepted the scholarships and will attend AMUG 2020. I’m certainly in awe, the experiences of our 2020 applicants in AM are astonishing, and it bodes well for AM’s future!”

Phoenix Analysis & Design Technologies (PADT), an engineering service provider, has launched its Online 3D Printing Glossary. PADT’s new website includes more than 250 definitions in nine different categories.

Eric Miller, Co-founder and Principal at PADT, said, “Our goal for the glossary is to help educate the community on the evolving terminology in our industry and serve as a critical resource for students and professionals seeking 3D printing knowledge and clarification.”

Nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s event? Have your say now.

Subscribe to the 3D Printing Industry newsletter to stay updated with the additive manufacturing news. You can also stay connected by following us on Twitter and liking us on Facebook.

If you are looking for a career in additive manufacturing, visit 3D Printing Jobs for the latest roles in the industry.

Featured image shows the Sliced logo on Mykita & Leica’s specially-developed eyewear. Original photo via Mykita.