Every year, Codex invites “scientists, engineers, entrepreneurs and visionaries” working at the forefront of technology and innovation to present their conference in London.

This year, as part of the the series on the “world’s top innovators from the industries of the future”, Codex has a conference session on 3D printing, where the ideas of innovators and their companies are greeted with a healthy mix of scepticism and enthusiasm from the audience.

ONO’s Filippo Moroni on democratizing design

Filippo Moroni, co-founder of 3D printing startup ONO is the first to present. ONO’s 3D printer was launched as a machine “for everyone”, via a kickstarter in 2016. To operate the printer, you need a printer, a phone, and resin. A photochemical reaction between light from the screen and resin hardens it into the desired shape. Moroni admits in his presentation that the ONO printer is “not the fastest, not the best, but the most affordable.”

The second part of Moroni’s presentation focuses on “democratizing” the process of printing, although his vision is not for everyone to have a printer in their home. “Our idea,” he explains instead, “was to create a large number of designs, and let people create them with a printer.” Together with the machine is an app. He compares the process again to children learning a new language, and with this language become the inventors of the future. Speaking to him afterwards, I get an idea of some more of the issues faced by ONO in printer development, problems as varied as resin availability and android sound compatibility. In spite of this both Moroni and his colleague Pietro Gabriele are optimistic about the future.

Pietro Gabriele has also promised that 3D Printing Industry will receive an ONO 3D printer within the next two weeks. So hopefully we will be able to answer some questions that many readers have already sent us.

Kleos and Magna Parva’s Andy Bowyer on space civil engineering

The second speaker, Andy Bowyer from Leicester-based Magna Parva admits that he is a bit of an “imposter” explaining that what Kleos, the project Magna Parva is working on is more accurately described as “continuous fabrication” or “space civil engineering”. However, there is certainly a large overlap between 3D printing and the process that Bowyer is describing. Since resin and carbon are less “risky” to take up and turn into structures than prefabricated parts, Kleos aims to concert them into structures using Mars-based technology.

While Bowyer does not elaborate upon the technology in question (and leaves before I can ask a question), he does outline some of the problems that Magna Parva are currently combatting, including transportation of resin into space free from radiation curing and producing structures without technological support. He leaves us with a bold prediction, that within two decades there will be structures in space kilometers in length.

Amos C. Breyfogle Stratasys and the race against the machine

Amos C. Breyfogle, who is based at Stratasys’ headquarters in Germany, is a senior application engineer and technical consultant. His presentation draws on his occasional role as an educator in helping teenagers understand additive manufacturing and its applications, and he draws on a variety of anecdotes to illustrate the importance of creative thinking when dealing with engineering challenges. “Engineers know how to do things the right way,” he says “and when they don’t, they ask themselves, what do I do with this new tool”, referring to first injection molding and now additive manufacturing.

He admits that additive manufacturing does not provide all the answers to engineering challenges, although “sometimes it’s not more effective, but its mostly a little more effective”. He ends with an apt aphorism to sum up his thoughts on the union between productivity and creativity. “Creativity is the only weapon we’ve got”, he says “if we want to win the race against the machine.”

Markus Glasser from EOS on overcoming the innovator’s dilemma

Markus Glasser, Senior Vice President at additive manufacturing giant EOS begins by drawing on the importance of disruptive technologies, stating that the next wave of “distruption is in production” and labelling additive manufacturing’s disruption as a “real driver” in manufacturing, one that is being increasingly being identified by all manufacturers.

As part of making a success of disruptive technologies, an organisation must adapt, by initially integrating all aspects of itself and then turning all of it to design driven manufacturing. “You must overcome the innovator’s dilemma” he says, referring to an organisation’s initial interactions with a disruptive technology, “and you need to define the key values you need for revenue”.

Glasser ends by interspersing motivational quotations with two other key ideas for a manufacturing business of the future. He suggests firstly that instead of one replacing the other, the traditional and digital manufacturing should be combined in the form of smart factories of the future. Finally, he suggests acting on interest, and training manufacturers interested in 3D printing for the long term, thus investing in the future.

ApisCor’s Nikita Chen-Yun Tai on the problems of 3D printing houses

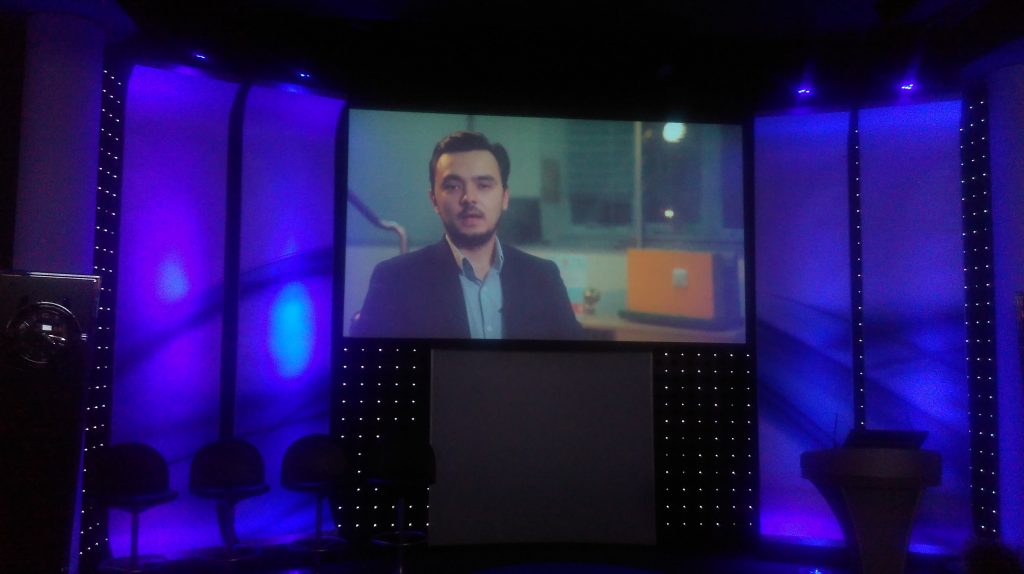

The final presentation from Apis Cor’s CEO Nikita Chen-Yun Tai is somewhat complicated by his absence (event organiser Rakesh Rawal explains that there were difficulties in obtaining a visa for him).

The pre-recorded video presentation given instead explains the process behind Apis Cor’s 3D printing of concrete houses, and noting the project’s success in 3D printing a house in 2 months. Chen-Yun Tai also draws on two key problems faced by ApisCor. The first is the 3D printing of horizontal structures in situ, owing to the difficulty of printing supports for these. The second is the difficulty of making the hardware accessible to all designers and architects. In spite of this, Chen-Yun Tai is confident of a solution by the end of 2018.

Dr. Douglas Terrier from NASA

The presence of 3D printing technologies at Codex wasn’t limited to this session, as Dr. Douglas Terrier, Acting Chief Technologist at NASA, spoke more about 3D printing in space in response to a question from our Editor in Chief, Michael Petch.

“Spare parts surprisingly are biggest consumable…taken into space, because…you can’t get one from a shop up there,” Dr. Terrier explained, noting how taking even just one of every spare part is incredibly expensive in mass – and therefore fuel.

“We’re actually working with a bunch of private sector companies working in this area, and we’ve demonstrated the 3D printing ability…on orbit, printing spare parts.”

A Futureproof tool

The presentations at the Codex event highlighted the importance of additive manufacturing on both a creative and technological level. Also, as the event brought together speakers and attendees from a wider group than many 3D printing conference it was also an opportunity to see how the technology is perceived beyond the immediate sphere of those who are already experts.

Based on conversations at the event, 3D printing still has some way to go to communicate it’s utility in a world crowded with information.

For more reports from events across the world, subscribe to the most widely read 3D printing newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the Codex Top 50 Innovators conference. Photo by Michael Petch.