Research conducted at Kitasato University in Japan demonstrates the use of a 3D printable, salt-based ink. The salt ink cuts the cost of 3D printable materials, and also exhibits properties similar to those found in natural bone.

The study published in the official journal of the International Society of Orthopaedic Surgery and Traumatology (The Société Internationale de Chirurgie Orthopédique et de Traumatologie or SICOT) explores the salt ink’s potential use in the medicinal area of surgical planning. However, acting as a plaster substitute, 3D printable salt ink could have wider application in small scale construction and the arts.

Fixing a ball and joint socket

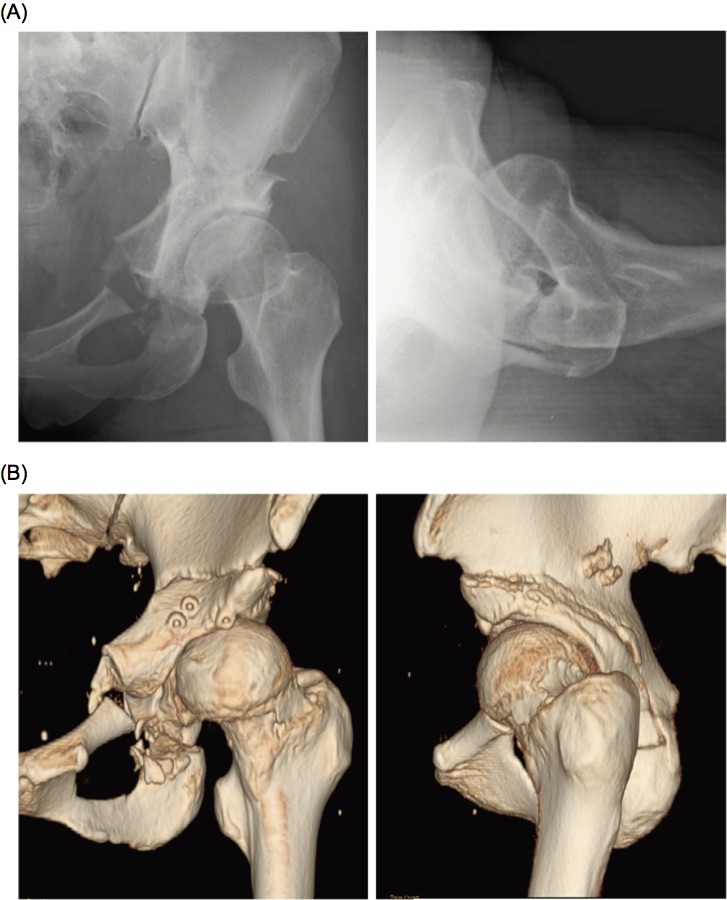

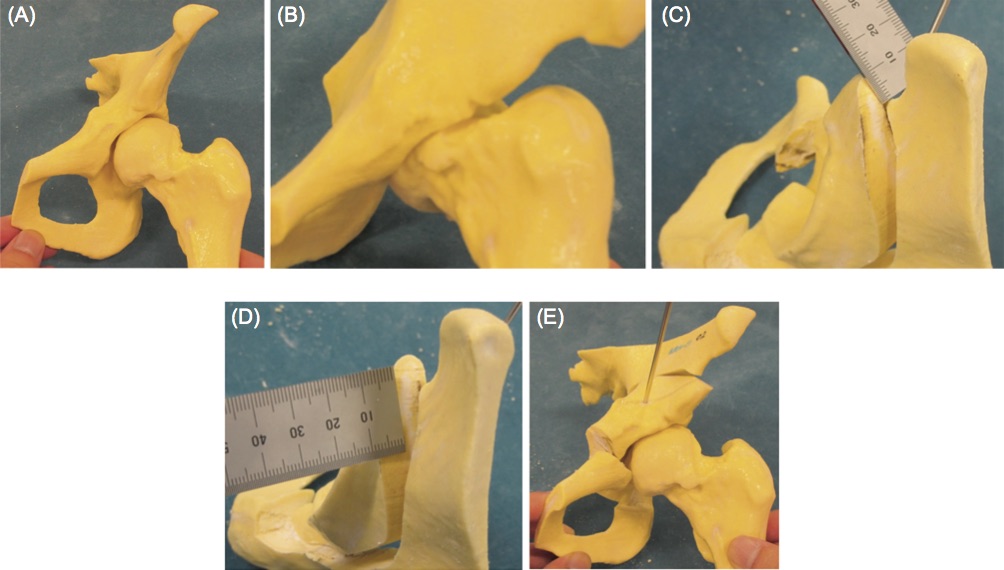

Kitasato researchers used their salt ink to recreate the bone of a patient suffering from developmental dislocation of the hip; a condition where the socket of a hip does not fit properly with the ball joint of the thighbone.

An accurate 3D printable model was made by using data from both a CT scan of the patient’s hip bone, and an x-ray image.

Surgeons then assessed the 3D printed salt model for all possible angles of operation. They performed an experiment with the same chisels and drills used in the regular procedure and found that the salt model could withstand the pressure without disintegrating.

The surgeons believe that the salt bone could also relieve the pain experienced by their patient through an operation. Having scrutinized the 3D printed salt model beforehand, the operation also doesn’t require the typical aid of a camera inside the incision.

Hip bone connected to the, thigh bone…

Hip operations are one of the most well-understood procedures in medicine. Developments relating to the hip are consequently more reliable when it comes to expanding the possibilities into other areas.

As the Kitasato University’s salt ink has only been trialed in a select number of cases, it is still too early to predict how far the development may travel. As another popular and well-discerned area for surgical guides though, we might suggest that this salt ink could be used for application on the spine. It would also be a welcome addition to operations on the skull, as such procedures can be incredibly complex and delicate.

, , , and

To stay up to date with the latest 3D printing research and news, sign up to the 3D Printing Industry newsletter here, follow us on Twitter @3Dprintindustry, or like us on Facebook.

Featured image shows a 3D photo of a human skeleton by Matthias Weinberger on Flickr