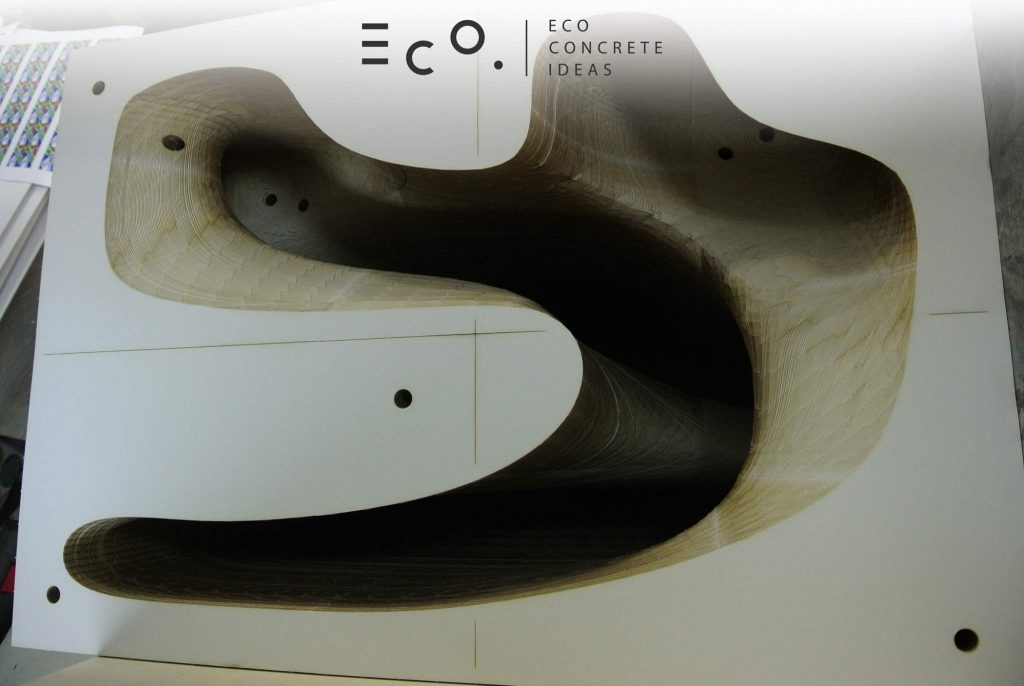

Digital cutting and creasing innovator Highcon has partnered with leading architecture brand Eco Concrete Ideas to create the stunning Morpheus bench. The 2 meter bench is the result of Highcon’s high-tech 3D modeling machines and Eco Concrete Ideas’ dedication to the development of new technologies. No stranger to cutting edge technology and creations, Highcon wowed viewers at last month’s unveiling of the Highcon Shape at a Drupa show. However, unlike the Highcon Shape, Morpheus shines as a breakthrough development in the worlds of architecture, designs, and 3D technologies.

The concrete bench will be unveiled by Eco in Taipei as part of a range of exhibitions in the capital city from July 9th until August 14th. Morpheus was created using Highcon Rapid Layer Manufacturing technology to cut through 4,000 layers of paper. The true innovation lies in the fast, low-cost production of the bench, an unprecedented feat in 3D technology. Using recycled board and no adhesive between layers, the initial production of Morpheus only took an astonishing three weeks to complete. One customer even managed to produce a mold in under a week on a Highcon digital cutting and creasing machine. Experts say that production with any other method, production would have cost much more and would have taken months to complete instead of days. With the creation of Morpheus, Highcon and Eco Concrete Solutions have managed to considerably drop the costs of mold production, while also cutting lead time.

The final product was printed on the Highcon Euclid digital finishing machine. With this machine and a 3D Modeling workflow solution that converts standard 3D models into separate layers, complex structures and textured can be produced that were previously impossible with other technologies. Now, fine details and smooth surfaces are creating instantly with minimal processing required.

Learn more about Highcon and Eco Concrete Ideas on their respective websites. Be sure to subscribe to our newsletter to stay up to date on all news!