Scientists from ETH Zurich have developed tiny 3D printed microbots that are capable of delivering drug payloads via blood vessels in the human body.

By combining soft lithography with electrochemical deposition, the team were able to fabricate multi-material vehicles that could be controlled via magnetic fields. In future, the scientists believe that their biocompatible microbots could be injected into patients during surgical procedures, and used to treat illnesses remotely.

“Metals and polymers have different properties, and both materials offer certain advantages in building micromachines,” said Carlos Alcântara, one of the two lead authors of the paper. “Our goal was to benefit from all these properties simultaneously by combining the two.”

The complexities of mult-material 3D printing

While interlocked mechanical structures have been widely-used in macroscopic machinery and nanosystems such as molecular shuttles, they’re not yet viable on a microscale. Despite their likely applications in soft robotics, they tend to be linked via organic synthesis, which prevents their integration with metallic materials.

Although soft lithography and microtransfer molding methods have shown promise in the past, interlocking parts made with dissimilar materials has remained challenging. However, given the medical potential of biodegradable bots carrying drug delivery reservoirs, the issue has become a hot topic of additive research.

Scientists from Oxford University for instance, have used an origami-inspired technique to fabricate microbots with shape morphing capabilities, but these too have limitations. The level of adhesion between the bot’s materials was still poor, and the process itself was found to only allow for a limited number of geometries.

In order to fully enable multi-material microprinting, the Zurich team proposed ‘weaving’ different metals and gelatin together to form an integrated microbot. By adjusting the pattern of such mesh-like structures, the scientists also theorized that they could be engineered to feature certain application-specific properties.

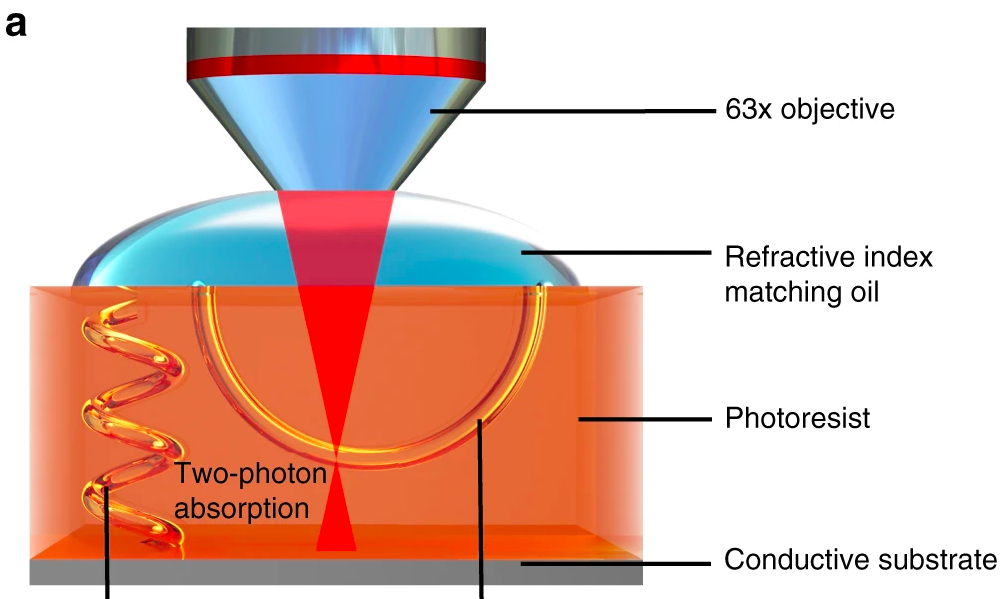

ETH Zurich’s novel microprinting method

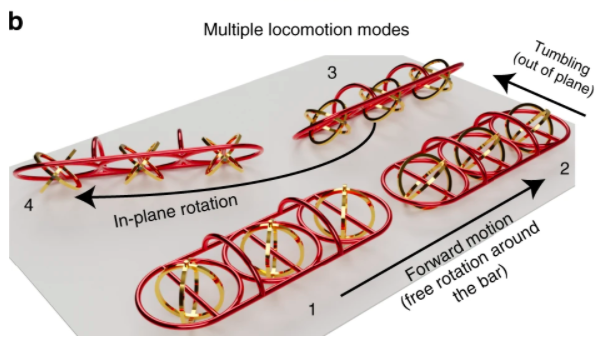

The Zurich team designed their microbot to feature the commonly-used metallic cage and helix shapes, which were mechanically interlocked by a polymeric bar. In theory, building a microdevice in this way allows the cage to freely rotate inside, which results in a tumbling action and ultimately in velocity and motion.

In order to turn their model into a working prototype, the scientists used a Nanoscribe TPP system to fill a prefabricated mold, then dissolved the template with solvents. During the process, the team found that they were able to 3D print two different geometries within a single step, yielding one interlocked microbot.

Further testing revealed that the devices could be created using shape-memory polymers and loaded with colored dyes, enhancing their drug delivery credentials. What’s more, the team were also able to manipulate the bots using a magnetic field against various levels of friction, and using different modes of rotation.

Other models were lated created with a PDMS hydrophilic frame, giving them the appearance of rubber ‘boats.’ These liquid-optimized devices were able to overcome significant resistance to propel themselves forward, meeting another important requirement of a blood vessel-faring drug delivery system.

Although the team conceded that 2PP remains too slow to enable the mass production of their devices, they still considered their approach to be a success. With further research, the scientists believe that their bots could be used not just for drug delivery purposes, but to implement surgical tools such as stents as well.

The endless march of micro-robots

The high-level of precision provided by 2PP 3D printing has enabled the production of various tiny experimental robots in recent years, but they often have very different purposes.

Researchers from the University of Grenoble have utilized 2PP alongside tailorable microbeads to fabricate a magnetically controllable Millenium Falcon. By changing the properties of the individual beads, the team also believe that it could be possible to create nanoscale microactuators for soft robotics applications.

Similarly, a team from Purdue University has leveraged 2PP to create distinguishable trackable microbots. By patterning the devices and deploying magnetic fields, the researchers were able to monitor and control their progress from a distance.

A team of scientists from Linköping University, has also developed a set of microactuators for soft micro robotics, but used extrusion 3D printing instead. The devices were fabricated using an electrically-charged polymer that could be deformed after printing, lending them 4D capabilities.

The researchers’ findings are detailed in their paper titled “Mechanically interlocked 3D multi-material micromachines.” The study was co-authored by C. C. J. Alcântara, F. C. Landers, S. Kim, C. De Marco, D. Ahmed, B. J. Nelson and S. Pané.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows two of the team’s 3D printed microbots. Image via ETH Zurich.