Spanish design group Nagami is collaborating with designers and architects, including Zaha Hadid Architects, as part of a new project, “Brave New World: Re-thinking Design in the New Age of Technology.”

Nagami will launch the project at Milan Design Week, April 17-22, with four 3D printed chairs. In last year’s Milan Design Week Zaha Hadid exhibited some of the cutting edge uses of sculptural 3D printing with their Thallus sculpture.

Rethinking design

Patrick Schumacher and Sebastian Anda, designers at Zaha Hadid, have produced two chairs for Nagami, “Bow & Rise.”

The designs are inspired by “structural optimisation processes typically found in nature.” Both chairs have been printed using a pellet-extruder with plastic PLA particles. Nagami believes the patterns and color gradients of the chairs reflect the designers’ desire to redefine the “spatial relationship between furniture and its setting.”

Bow & Rise measure 780x810x1180mm and 705x640x1060mm, respectively. The PLA used is from renewable sources, including corn-starch.

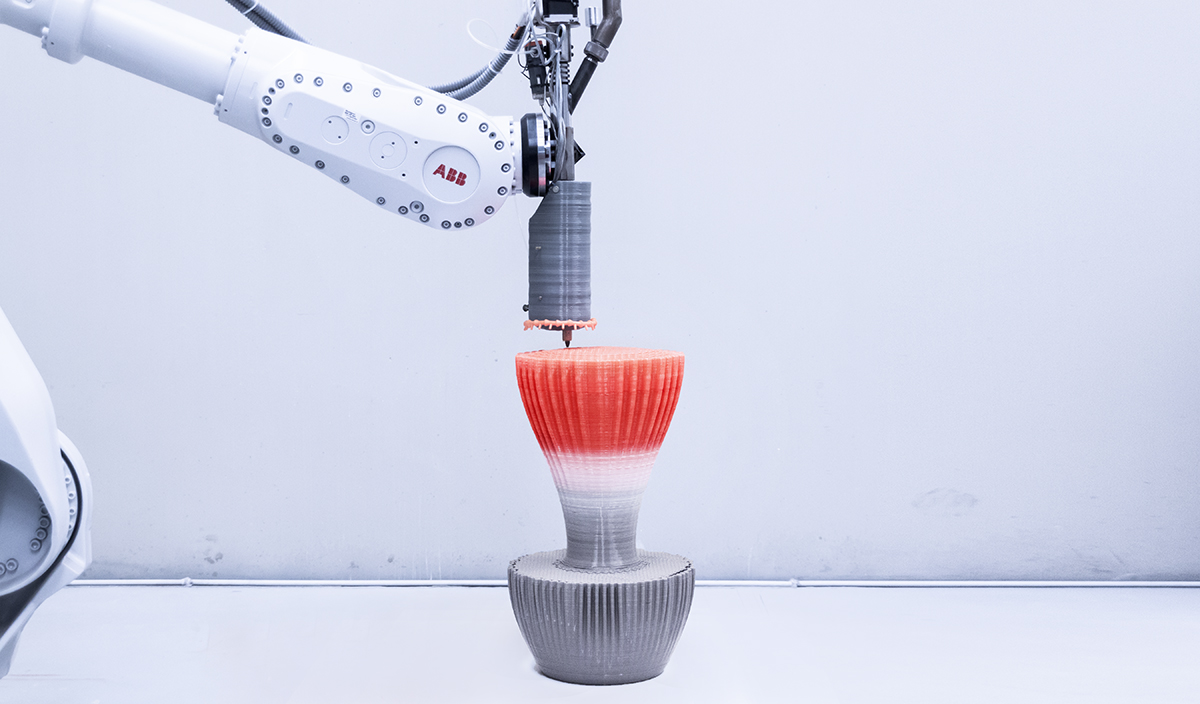

“Robotica TM”, by industrial designer Ross Lovegrove, is similarly inspired by nature, designed with the intersection of botany and robotics in mind.

The high stool, built from “rotational geometry”, is designed to be accessible from any angle and performs multiple functions as a table or a sculptural plinth. The stool features silicone inserts allowing the placement of hot objects, such as dishes just out of the oven. It measures 445x445x758mm.

Architect Daniel Widrig, who has previously collaborated with Materialise to design 3D printed wearable sculptures, has produced the “Peeler” chair. The chair has “been designed to satisfy both the ergonomic constraints of the human body, as well as the ergonomics of the robotic arm that prints it.”

Printing the chair takes just a few hours. Nagami says the Peeler’s undulating and skin-like surfaces are the result of the intersection of “human and machine requirements”. The chair is 3D printed using PLA and TPE in a shelled structure featuring 7mm thick walls and measuring 670x570x880mm.

3D printing enabling design

Nagami founders Ignacio Viguera Ochoa, and Manuel and Miki Jimenez Garcia say the company “designs products that until now were just waiting for the right technology to come to life: not only objects that you can hold, but also that you can feel and experience as part of your environment.”

Nagami is continuing a trend at recent Milan Design Weeks for the incorporation of 3D printing into product design and manufacture.

United Nude and 3D Systems exhibited strange and wonderful 3D printed architectural shoes in 2015. At last year’s Design Week, Steelcase unveiled a new method of 3D printing, “rapid liquid printing” for interior design.

Follow all the latest 3D printing updates from the Milan Design Week. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Vote for the Innovation of the Year in the 2018 3D Printing Industry Awards.

Our 3D Printing Jobs service is now live. Post a job or advance your career in 3D printing now.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your entries now for a chance to win a 3D printer.

Feature image shows Robotica by Ross Lovegrove. Photo via Nagami Design.