XJet, a provider of ceramic and metal 3D printing solutions based in Rehovot, Israel, has officially launched its “breakthrough” Carmel 1400 and the Carmel 700 Additive Manufacturing (AM) systems.

Both systems are powered by XJet’s trademark NanoParticle Jetting (NPJ) technology, and coincide with the delivery of the firm’s first ever machine to an off-site customer.

Hanan Gothait, CEO and Founder of XJet, and Dror Danai, the company’s CBO, discuss the two systems, giving details of an upcoming preview at formnext 2017.

Monster machines

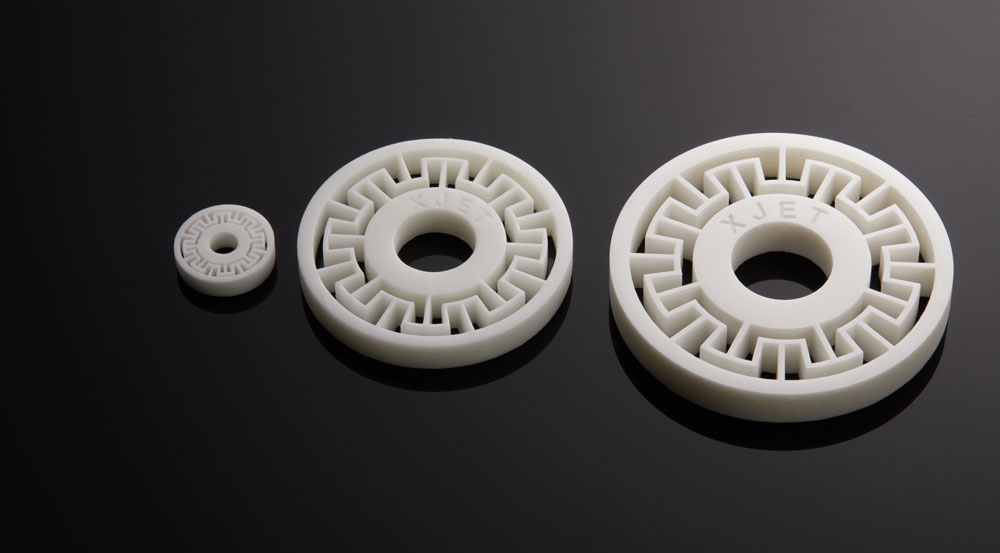

The XJet Carmel 1400 has a 1,400-square cm build plate, and a maximum build height of 7.9 inches, making its 3D printing capacity one of the largest in the industry. The Carmel 700 by comparison has a slightly smaller smaller build envelope at 500 mm x 140 mm for more “cost-effective” production.

Ceramic and metal components can be made using both systems, with the option to add ceramic as removable support material to a metal part build.

One of the main features that sets XJet’s NPJ apart from competing methods is that, as Danai explains in a previous interview for 3D Printing Industry, “we never melt the metal.” Instead, the metal particles are suspended in a unique liquid formulation that is removed afterwards when parts are sintered.

An animated demo of the NanoParticle Jetting process. Clip via XJET NPJ on YouTube

Processing without powders

CEO and Founder Hanan Gothait explains, “NanoParticle Jetting™ technology is a unique 3D inkjet technology that redefines additive manufacturing for metals and ceramics,”

“Other additive manufacturing technologies use powders, but we offer a real breakthrough by leveraging our know-how as pioneers of both inkjet printing and 3D printing industries.”

Currently XJet are working with only one build material, ceramic, but as Gothait adds, “we could theoretically print multiple build materials.”

Relying on an inkjet-based technology means that NPJ is capable of attaining fine layer resolution, and complex geometries in what Gothait terms, “a very simple and very safe process.”

XJet’s first customer

XJet CBO Dror Danai confirmed that the Carmel 1400 system “has already been delivered to a customer site” with further details and demo of the system to be revealed at formnext 2017 in Germany from 14-17 November.

3D Printing Industry will be reporting live from the event. To be the first with the news, subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Featured image shows a digital demo of XJet’s trademark NanoParticle Jetting metal 3D printing process. Image via XJet NPJ