Mouser Electronics Inc. and Grant Imahara have announced the winning design in the International Space Station (I.S.S.) Design Challenge has been 3D printed in space.

Andy Filo, an engineer based in Cupertino, designed the satellite-launching device that is now in orbit. It is hoped that eventually the 3D printed device for the testing and deployment of Femto Satellites for the Internet of Space may be used by astronauts on missions.

The challenge set was to “help astronauts aboard the International Space Station with a device that improves their jobs or daily life.” As previously reported by 3D Printing Industry, Mouser Electronics Inc are frequent sponsors of such challenges. The satellite-launching device was 3D printed using Made In Space’s Additive Manufacturing Facility (AMF), who recently told us more about how 3D printing is advancing the space industry.

3D printing in a zero-g environment

Filo’s winning design was chosen from 242 entries and digitally transmitted to the I.S.S. The engineer explains more about the motivation for the project,

Femto Sats detect Solar activity, Asteroids and Cosmic Rays that affect life on earth and space. Deploying them in a pattern is important to the network’s geometry. Attempts to observe deployment in a 1G environment or aboard a Zero G jet flight are inadequate (they hit the floor or ceiling). This requires the Zero G laboratory of the ISS. The experiment will use Sprite Femto Satellites. A crew held Deployer printed aboard the ISS will serve as host. All components are designed to printed, assembled, loaded and operated in a zero-g environment. ISS crew would operate and video the experiments. Femto Sats loaded in the Host. All are powered by CR2032 batteries.

Bringing together engineers and makers from around the world

“Mouser is excited to be part of new and innovative projects that bring together engineers and makers from around the world and — in this case — beyond,” said Glenn Smith, President and CEO of Mouser Electronics. “Andy’s femtosatellite-launching device meets the needs of astronauts as well as earthbound researchers and engineers.”

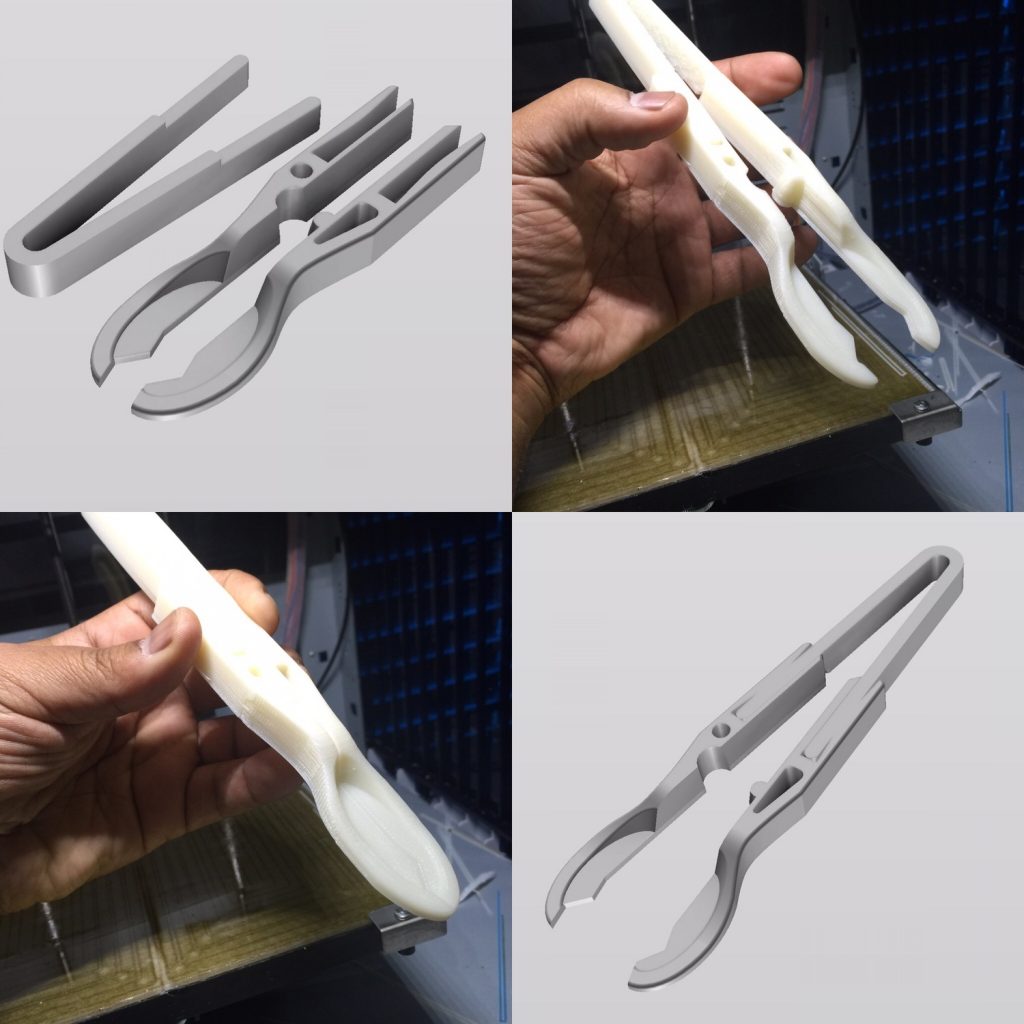

Other notable entries in the competition included 3D printable Space-Tongs an, “eating utensil that will allow the astronaut to eat food from a pouch.” The designer explained the advantage of 3D printing the utensil,

Is to minimize the amount of components needed to feed the astronauts which will save space and weight. And since it can be 3D printed it will free up space and weight for transport. By printing this utensil in a food safe material such as HDPE this utensil could also be washed or sterilized for reuse.

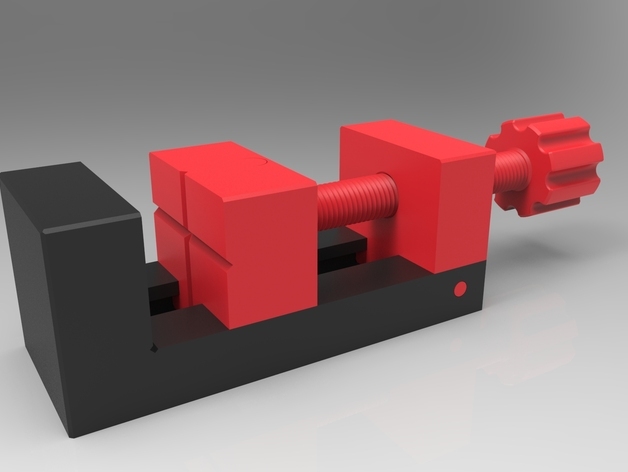

Thomas Delmas designed a 3D printable workshop vice to allow astronauts, “to work easily” on projects in space.

For more applications of 3D printing in space, read our article about 4 enterprises who are using 3D printing to reach space.

For all the latest 3D printing news, subscribe to our free newsletter here and follow our active social media accounts.

Also, don’t forget that 3D Printing Industry readers can vote now in the 1st Annual 3D Printing Industry Awards.