Back in March of last year, we reported on a small Korean plastics company that was working on a new PLA/Metal filament for 3D printing. They were making great progress, but hadn’t perfected their formula yet, so they went back to work and we didn’t hear much from them… until recently. It seems that the PLA/Metal stuff wasn’t the only project they had going, and their newest filament, which is about to be released, is sure to get some serious attention.

The aptly named BnK (Books and Kimchi) Chemical Corporation was founded in 2009 to provide polymer components for the Korean automotive and construction industries, but has moved into the 3D printing realm to become one of the very first domestic FDM filament manufacturers in South Korea. Back during our first meeting, Kim Young Soo, Management Team Leader for the company, told us that he could see that there are several applications that 3D printing could be put to, but that new types of feedstocks were needed. He said that it was his company’s intent to explore and develop new ones, and that to this end, they had opened a new research and development center.

Well, it seems that they have put that research center to good use, as they have just informed us they have a new filament ready for market. According to BnK, their new filament is a PLA-based antibiotic/anti-microbial filament and has the ability to kill germs that it comes in contact with, which makes one wonder at the possible uses of such a filament!

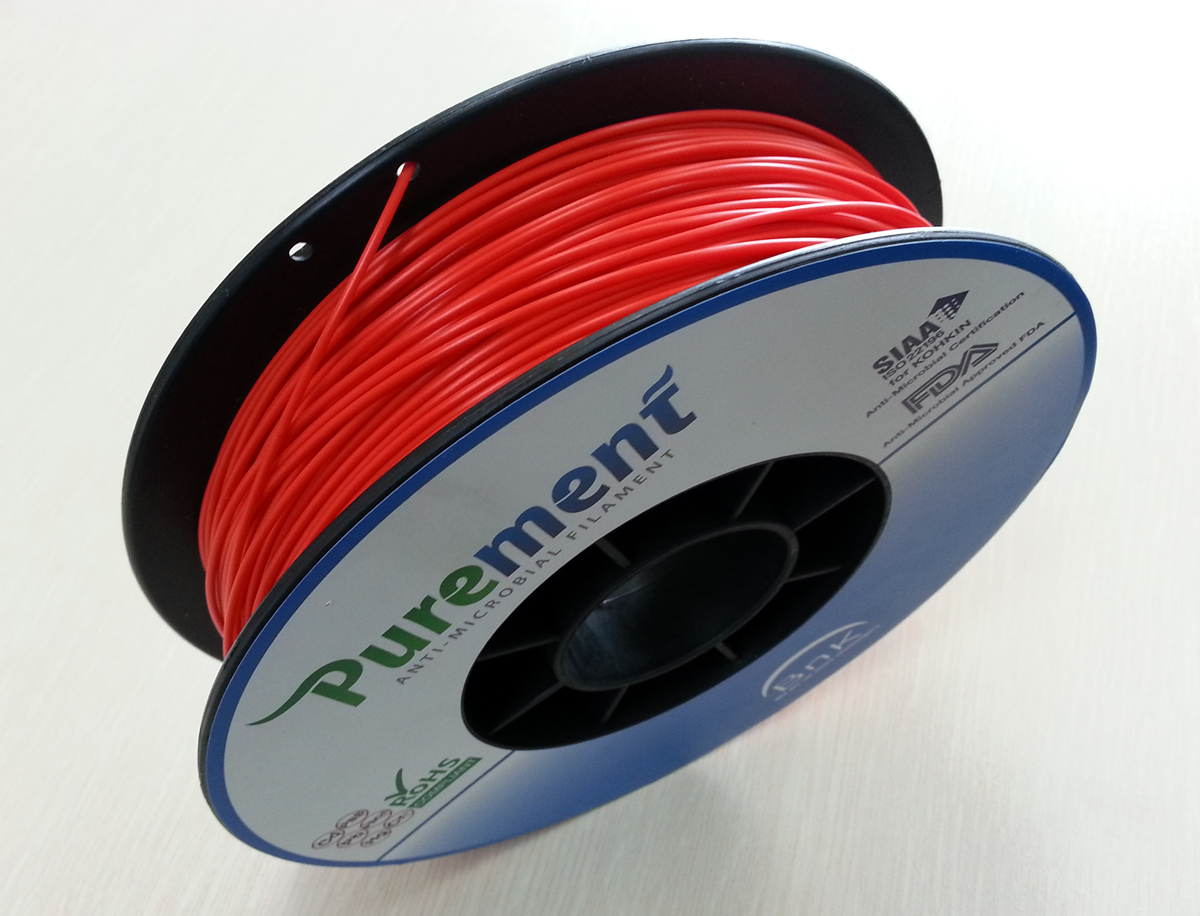

The company is calling it “Purement” as in “pure filament” and told us that it is now protected by a Korean patent, and has US and International patents pending. According to BnK, Purement uses inorganic antibacterial ingredients, as these ingredients are more durable (up to 2 years, they said) than organic compounds. They also told us that the active ingredients they used have been approved by the FDA and SIAA (Society of International sustaining growth for Antimicrobial Articles) for antibacterial purposes, and the filament’s antimicrobial effect was certified by KOLAS and eliminated 99% of the germs tested (colon bacillus and staphylococcus aureus). They also said that it was tested by SGS in accordance to US FDA 21 CFR 177.1520 and had passed.

In addition to everything else, the filament was also certified as RoHS (Restriction of Hazardous Substances) compliant; meaning that it doesn’t contain lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers. These restricted materials are hazardous to the environment and pollute landfills, and are dangerous in terms of occupational exposure during manufacturing and recycling. RoHS, also known as Directive 2002/95/EC, originated in the European Union and restricts the use of specific hazardous materials found in electrical and electronic products.

Kim Young Hyeok, a Senior Research Engineer at BnK, said his motivation to produce this filament was his love of 3D printing and the safety of his family, “I thought that many filaments were not suitable for home and school use. The output of 3D printers are still considered new and unexpected to many people, so the outputs are often passed around and shared. I got the idea of putting an antibacterial effect in the plastic to prevent the items from becoming disease spreading sources. Purement has been proven to kill two nasty germs; colon bacillus and staphylococcus aureus. Hopefully this development will help 3D printing to be adapted into our schools, homes and daily lives in a safer manner for everyone.”

Mr. Kim explained to us that 3D printed products like toys, education materials, kitchen tools, and household items can, due to their layered construction, provide a favorable environment for germs to thrive. Even after thorough washing, it is often not possible to completely clean these items. With items made of Purement, bacteria and germs find that the tiny nooks and crannies of 3D printed items are not so appealing, and this reduces the risk of spreading germs.

For this article, Mr. Kim provided us a sample spool of BnK’s new filament so we could test it ourselves and run it through our printers to see how well it printed. He gave us a bright roll of their “Traffic Red” Purement to use. We examined the filament carefully and it appeared smooth, round, and consistent in its dimensions. Though our experiments were rather unscientific, the filament appeared to be, in every way, of a very high quality. When bent, the filament was flexible and not brittle at all, and found that it was far easier to use scissors to cut it, rather than breaking it off by hand, as we do with most PLA we use. Color was consistent all the way through the strand and showed no discoloring that we could find.

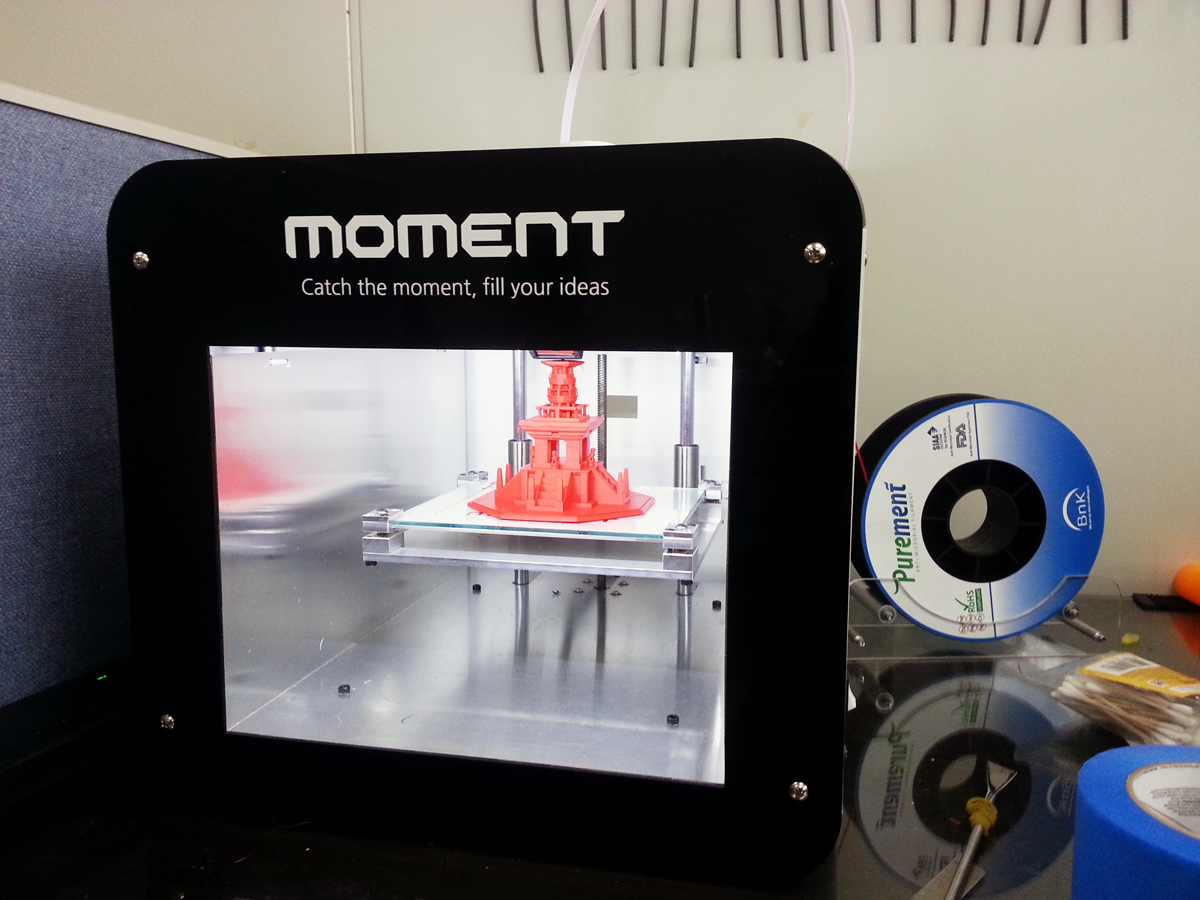

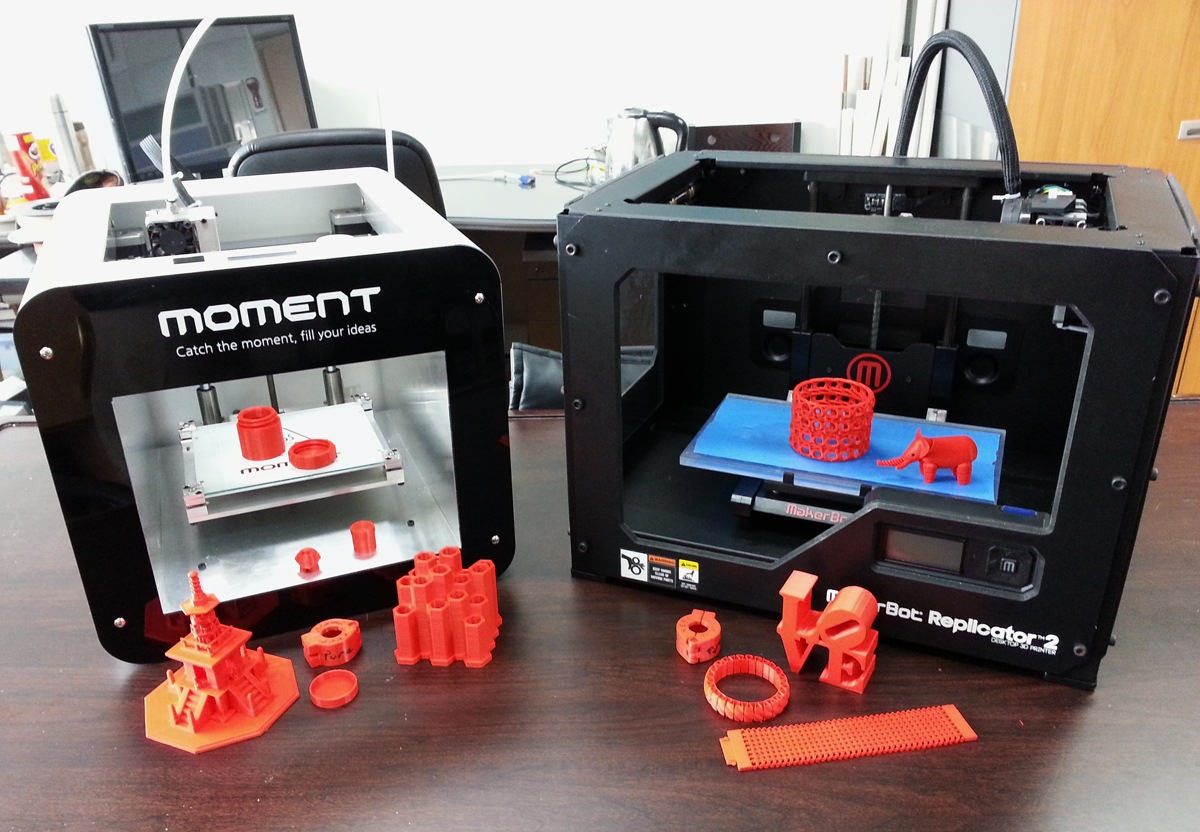

Running the Purement through our available printers (a MakerBot Replicator 2 and a Moment 3D) we found that it worked very, very well. We printed out a number of different items on each printer, and found that, in every case, the filament performed excellently. Regardless of shape, or printer used, our test prints were solid, smooth, and very well defined. None of the samples printed showed any signs of trouble sticking to the buildplates. On the MakerBot, we used blue painter’s tape and, for the Moment, we just used its clean, heated glass for the build surfaces. None of the prints made showed even the slightest delamination, and a few that we could fill with water did not leak. Purement performed, in every way, consistently with the highest quality PLA filaments we have seen. And, most importantly, during the entire time we used the Purement filament, we did not have a single print failure…on either machine!

As I said, we received a roll of BnK’s bright “Traffic Red” Purement, but it also comes in 11 other colors, from Magenta to Mint Turquoise, from Dutch Orange to Fluorescent Green. The colors all seem to be bright and colorful, and should produce excellent prints. I really look forward to trying some of their other colors in the near future. BnK’s website is still under construction, but the address will be www.bnktech.kr, so check into it when you can.

When asked about the metal/polymer filament that we had spoken about when we first met, Mr. Kim advised that it is still in development, but that it should be ready for market sometime next year, possibly around summertime. Keep your eye on this little company, for who knows what interesting things Books & Kimchi may come out with next. Currently BnK is seeking distributors and resellers for their new filament line, so if your company is interested in becoming a partner, you can contact BnK directly via email at: [email protected] and [email protected].