Weerg, an Italian 3D printing, and CNC service provider has launched new Acrylonitrile Butadiene Styrene (ABS)-like grey and Tmax transparent 3D printing materials.

The resins are designed to achieve the same mechanical performance as ABS materials, and to replace ABS in producing prototypes, parts, and functional components in the automotive and mechanical fields.

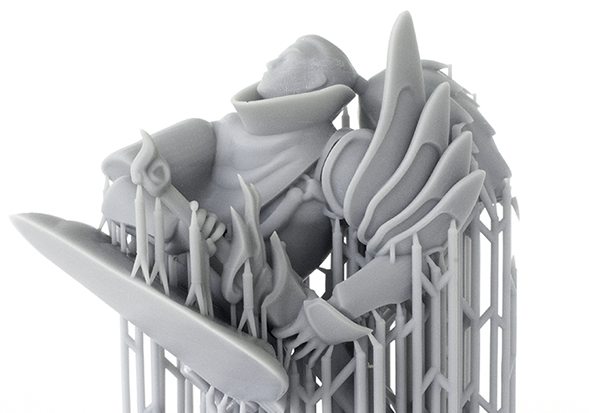

“A few days after the release of this new material, numerous requests have already been received, both for mechanical fittings and for miniatures and prototypes with a high level of creativity, intended for unusual sectors such as packaging for cosmetics”; said Matteo Rigamonti, Founder of Weerg.

Weerg’s new ABS-like materials

Launched in 2015, Weerg’s online 3D printing service allows customers to upload 3D files, which are then manufactured using the company’s 3D printers and CNC machines. In addition, Weerg provides quotation, delivery and advisory services for clients, and gives full Non-Disclosure Agreement (NDA) protection to any CAD files uploaded.

The newly added materials are available in three resin formulations: classic, performance and top mechanical. Customers are therefore able to choose the resin that best suits their processing needs, based on the levels of stress that the molded component will be subjected to.

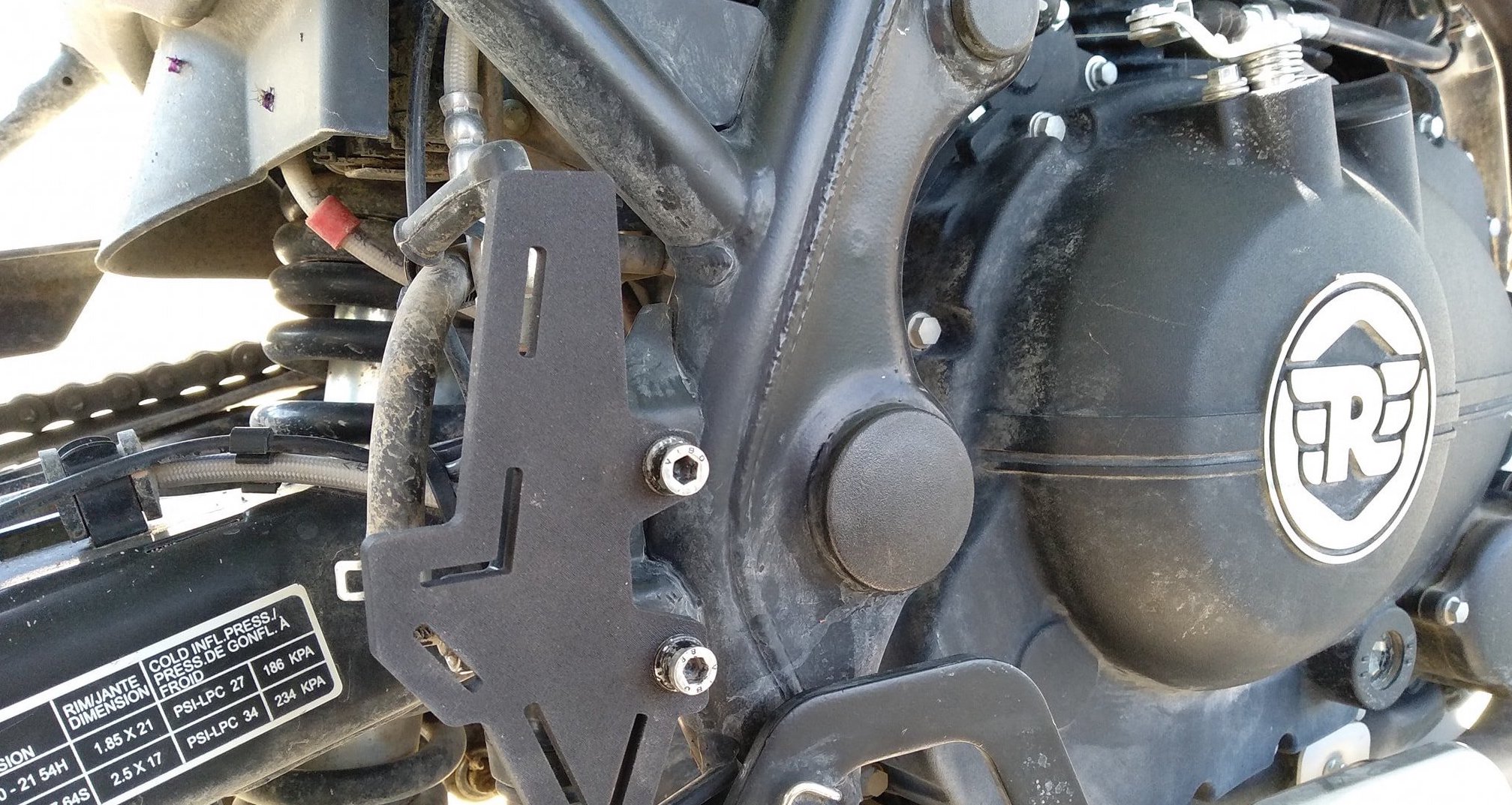

Weerg’s new resins can be used to 3D print solid, high surface quality parts up to 58x120x159 mm at resolutions of 0.5 mm. Potential applications for the materials therefore exist in the automotive and mechanical sectors as well as the creation of aesthetic models.

The ABS-like resin’s grey colour, allows for subsequent finishes such as paint to be applied. Painting onto a grey surface also prevents the product from turning yellow, as can sometimes be the case with black and white materials. Tmax on the other hand, is available in glossy and satin versions, which makes it ideal for producing prototypes or components that need to remain visible in the final product.

Weerg used its proprietary 4KSPER™ technology to produce the new resins, which join the company’s existing range of Nylon PA12 materials, and Rigamonti says the two resins are just the first of many.

“The activation of the production line dedicated to resin represents a first advance of the novelties that Weerg has prepared for the 3D printing sector”, said Rigamonti. “Our research and development department is already working on introducing new, even more effective materials, but also on applying new top secret finishes,” he added.

Alternatives to ABS within the 3D printing industry

As ABS is increasingly adopted in additive manufacturing, researchers have sought to develop ABS, to enhance its lightweight and impact resistant qualities.

A July 2018 Oak Ridge National Laboratory (ORNL) study describes improved inter-layer adhesion enhancements made to ABS by mixing it with lignin, rubber and carbon fiber.

Australia’s ARC Centre of Excellence for Electromaterials Science (ACES) published a study in January 2019, introducing a method of making ABS five times more thermally conductive by mixing it with a microdiamond powder.

German-based large-format 3D printer manufacturer BigRep, added new Acrylonitrile Styrene Acrylate (ASA) and ABS materials to its portfolio last week. The new materials were added for use with BigRep’s STUDIO G2 and PRO (ACE) Fused Filament Fabrication (FFF) 3D printers.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Weerg’s HP 5210 3D printers, which it uses to produce parts for customers. Photo via Weerg.