Weber Beamix has announced that it is buying out fellow construction firm BAM to take full control of the companies’ joint concrete 3D printing factory in Eindhoven.

Since opening in 2019, the complex has become a Dutch AM innovation hub, where designers and state provinces alike have come to create optimized infrastructure and architectural elements. By acquiring BAM’s shares, Weber Beamix aims to streamline the facility’s operations, and it believes that independence will allow it to better draw the attention of the Netherlands to concrete 3D printing’s potential.

Weber Beamix’s concrete ambitions

Both well-established building firms in their own right, Weber Beamix and BAM have collaborated for at least four years, since they first 3D printed a concrete bridge in Nijmegen. Following their initial success, the companies opted to open a co-owned industrial-scale additive manufacturing facility in 2019, which BAM claimed at the time would “end the technology’s experimental stage” in construction.

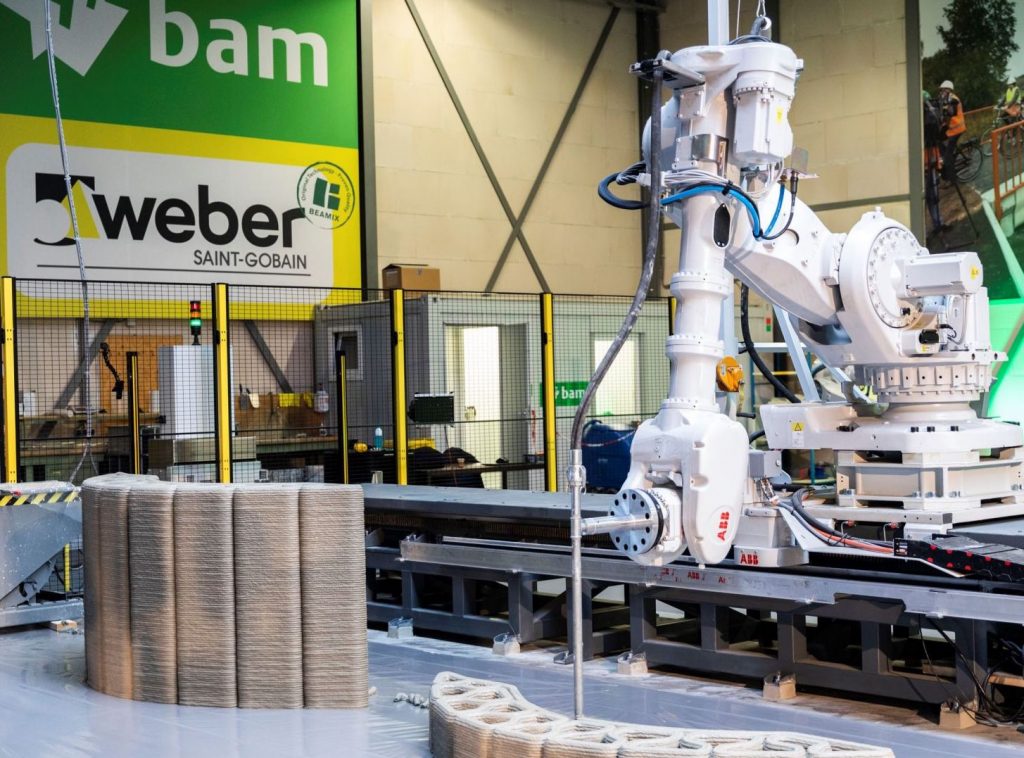

The indoor factory, which houses robotic arm-mounted 3D printers, enables the creation of formwork as well as other large-scale architectural elements, and its facilities were recently deployed by Weber Beamix, the Eindhoven University of Technology, Van Wijnen, Vesteda, Witteveen+Bos and the city of Eindhoven, as part of a wider Dutch home-building project earlier this year.

BAM and Weber Beamix are also leveraging the factory’s machinery to create the world’s longest 3D printed concrete pedestrian bridge. Even though the structure is now in the process of being built in Nijmegen, the bridge itself was additive manufactured in Eindhoven, at the companies’ now-previously co-owned complex.

Following Weber Beamix’s mutually-agreed buy-out, BAM has indicated that it’ll continue to acquire access to the facilities when this “adds value for its customers.” Weber Beamix, meanwhile, has acknowledged BAM’s role in introducing 3D printing “as a construction method in the Netherlands and abroad,” and stated its intention to intensify its related development and production activities.

Having taken full control of the concrete 3D printing factory, Weber Beamix has also committed to focus on sustainability, industrialization and digitization moving forwards, as it seeks to address the construction market independently, and pitch its large-scale manufacturing capabilities to other local provincial authorities.

Novel Venetian 3D printed architecture

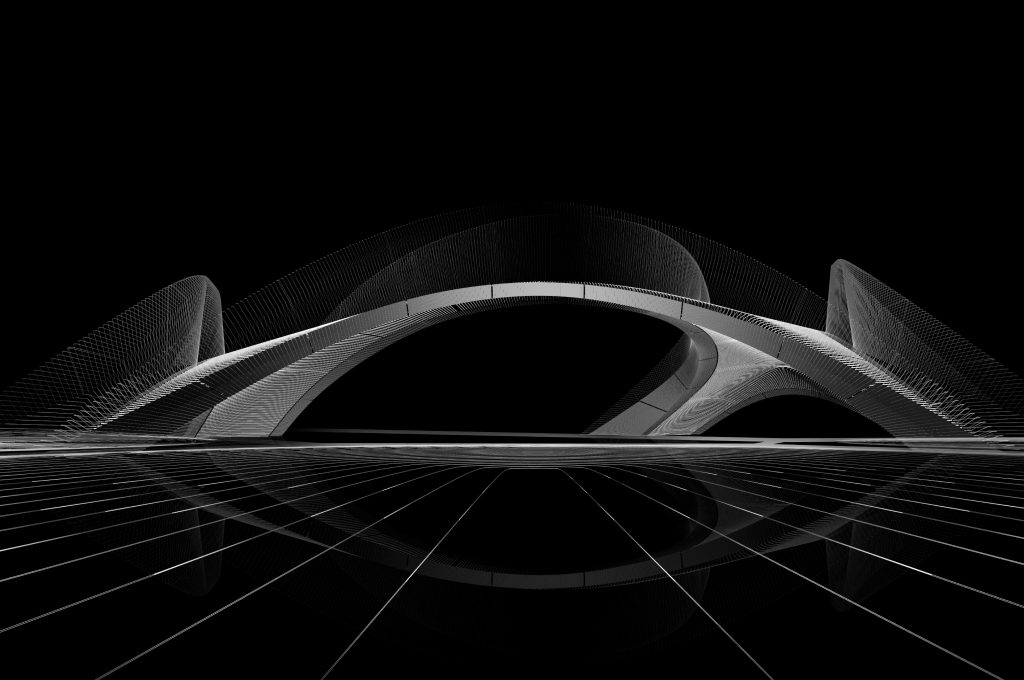

Switching from Northern to Southern Europe, a collaborative team from ETH Zurich, Zaha Hadid Architects, incremental3D and LafargeHolcim, are currently 3D printing a novel arched bridge in Italy. Nicknamed ‘Striatus,’ meaning ‘grooved’ or ‘striped,’ the structure is being built at the Giardini della Marinaressa gardens, for display during Venice’s Architecture Biennale 2021.

It’s likely that the bridge has been named after its ridged surface texture, but little has been made public about the technology behind its construction. For its part, LafargeHolcim has said that the structure is set to support itself without reinforcement, standing only thanks to compression forces, effectively “establishing a new language” for concrete construction.

By combining masonry with advanced technologies such as computational design and robotic manufacturing, the firm also says that the bridge will only use materials where needed, reducing its wider footprint. Similarly, given that the team are assembling their design without using binders, unused concrete can be continually repurposed, allowing them to build more complex architecture less wastefully.

Once finished, the bridge will reportedly measure 1600 meters in length and weigh up to 1000 kilograms, taking a total of 140 hours to complete, with the final product set to be exhibited as part of the “Time Space Existence” exhibition hosted by the European Cultural Centre (ECC) from 2 May 2021 to 21 November 2021.

Building bigger and better bridges

As construction 3D printing technologies continue to advance, bridge-building architects and firms are becoming ever bolder and more ambitious with the complexity of their designs. Large-scale 3D printing firm XtreeE, for instance, has been contracted to create a lavish 40-meter pedestrian footbridge in Paris for the 2024 Olympic Games.

Similarly, Dutch engineering consultancy firm Royal HaskoningDHV has continually worked with materials producer DSM to push the boundaries of additive manufactured infrastructure in recent years. The firms worked with CEAD to design an ultra-lightweight fiber-reinforced bridge back in 2019, before 3D printing a sustainable footbridge in Rotterdam using recyclable source materials in July 2020.

Holland has become a somewhat of a hotspot for construction 3D printing companies, as Vertico has also been highly-active in this area over the last few years. The firm has previously worked with the University of Ghent, to additive manufacture a material-efficient footbridge, using 60% less concrete than conventional construction technologies would have required.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Weber Beamix’s concrete 3D printing factory. Photo via Weber Beamix.