The prospect of 3D printed house is drawing closer as 3D printing for construction means designers can be bolder than ever before.

Branch Technology is a freeform building firm behind some of the largest 3D printed structures to date. Searching for ways to really push its KUKA-powered process, the firm launched the Freeform Home Design Challenge.

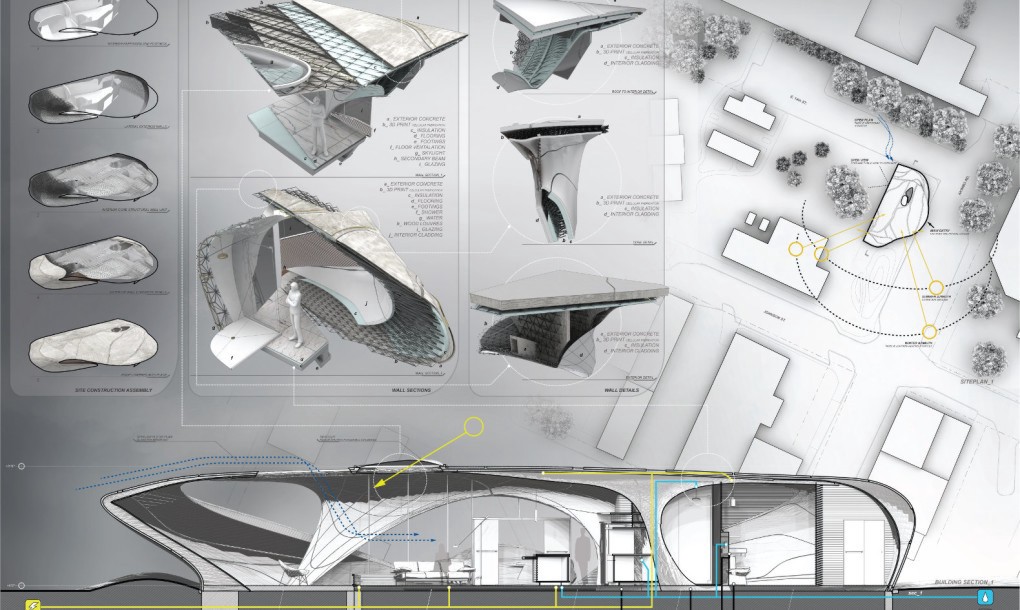

In 2016, WATG Urban, a design studio headquartered in Illinois, took home first prize in the competition stunning judges with its natural, “Curve Appeal” concept that sought the make the most of natural light and the Tennessee Riverside.

Now two years later, WATG has announced that “the wall section testing, research, and development phase” of the Curve Appeal 3D printed house is “currently underway.”

Freeform building

Shaped like a conch shell, WATG’s Curve Appeal will employ Branch Technology’s trademark Freeform 3D printing process to build a kind of gypsum-composite structures.

United States Gypsum is helping the team research suitable structural reinforcements for the house, including gypsum spray foam.

Working with engineering, investigation and analysis experts at Thornton Tomasetti, WATG is testing the load bearing capabilities of Branch 3D printed beams and wall sections. Without fine-tuning or optimization, initial experiments show a 5 pound, three-foot-long beam is capable of supporting 3,600 pounds.

Ecofriendly and bright

Structural support will also be added by smart material deposition, pin pointed by spring points throughout the floor plan. According to the designers, this will allow “the structure to carry roof loads and provide large open-plan living spaces, shaping structures in new ways without any restrictions.”

All-importantly, WATG and Branch Technology have also employed a company called Interface to help design “high-performance mechanical, electrical and plumbing” for the house to make it “net zero-energy,” i.e. “the house will produce as much energy as it consumes, reducing its carbon footprint.”

Constructive customization

The hope of the Curve Appeal project, and other concepts in development at Branch Technology is to bring more customization into construction. Reflecting on the Freeform Home Design Challenge Platt Boyd, Founder and CEO of Branch Technology, says, “This project is the first example of what’s possible with 3D prinitng. When a person can customize their home, and add their fingerprint to it that makes them feel a much greater part of the process.”

The first results of WATG’s rigorous development are expected to “breaking ground later this year.”

Keep updated – subscribe to the free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Is 3D printing for construction an award winning application? Make your nominations in the 2018 3D Printing Industry Awards here.

Featured image shows concept drawing of the WATG Curve Appeal 3D printed house. Image via WATG Urban