Cellulose is the most abundant organic polymer in the world. It is the primary compound in the cell walls of green plants, and is typically used to make paper and cardboard.

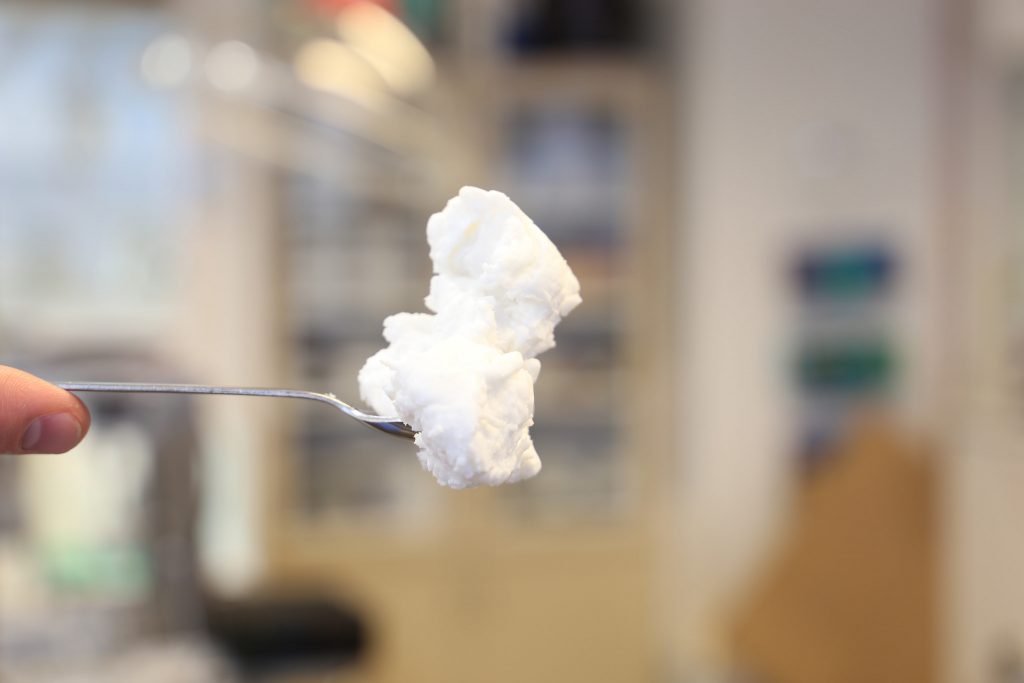

At the VTT Technical Centre of Finland, a state owned research and development non-profit, scientists have used nano-structured cellulose to make a 3D printable material.

The nanocellulose paste is now in development to make smart-dressings that heal and monitor skin wounds.

Materials

Alginate, found in the cell walls of brown kelp, is the material used to make antibacterial gel that can support the viability and proliferation of living cells. It is commonly used in bioprinter ink solutions, to 3D print scaffolds for cells to cling to and form bonds.

Instead of making a hydrogel like alginate, which is composed almost entirely of water, nanocellulose can be used to make a kind of paste. Though nanocellulose can behave like a hydrogel in its semi-solid gel state, the matter is composed of fibers just 5–20 nanometers in width. This gives the material superior water-absorption properties, that are key to keeping wounds healthy and clean.

The smart device

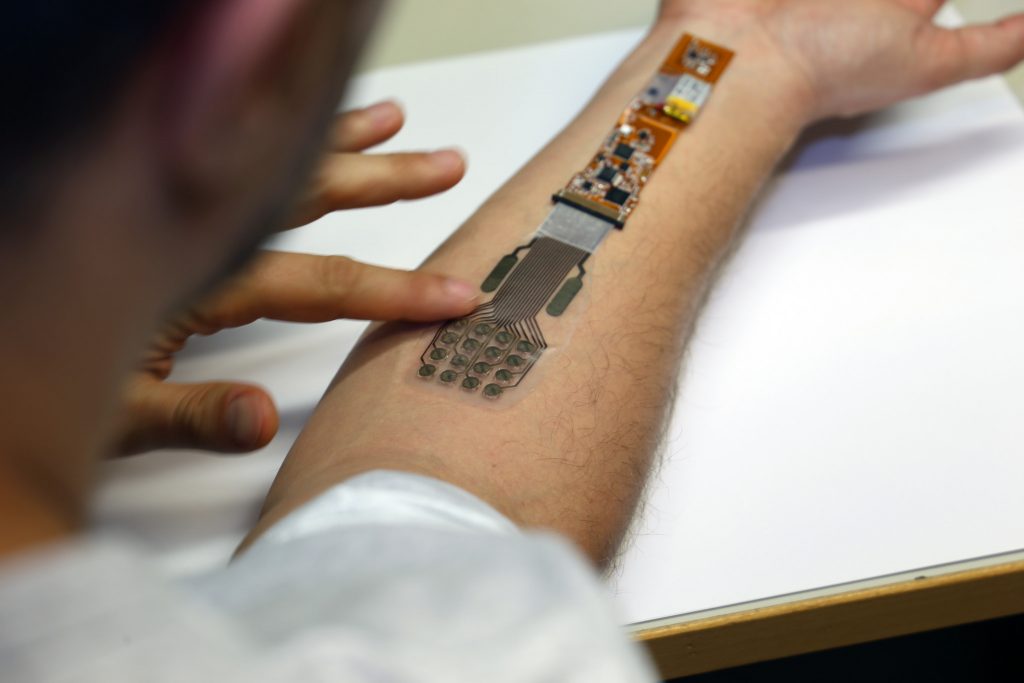

VTT’s wound dressing combines a nanocellulose paste with a printed electronic circuit board. Measurement electrodes are printed onto a film of nanocellulose combined with polyurethane. These electrodes are covered by another clear film, and then a nanocellulose care gel is 3D printed on top.

When applied to the patient, the care gel is placed in contact with the skin. The printed electrodes can be tapped by VTT’s FlexNode reader for wireless transmission of temperature data and bioimpedance, i.e. tissue composition, used to aid patient care.

Three times better than alginate

According to Panu Lahtinen, a Senior Scientist a VTT, “By using nanocellulose, we have succeeded in creating 3D structures that absorb liquids three times more efficiently than the compared alginate fibre dressings commonly used in wound care.”

The material is yet to achieve FDA approval for its widespread application in medicine. However, many reserach institutions have become advocates of the cellulose’s unique, green and antibacterial properties.

Studied by Wyss, MIT and the military

A collaboration between the Wyss Institute for Biologically Inspired Engineering, the Swiss Federal Laboratories for Materials Science and Technology, and ETH Zürich made a groundbreaking discovery in the materialization of cellulose with their paper published in March 2017.

The Massachusetts Institute of Technology (MIT) has also been using the plant material to make inks for FDM 3D printing.

In wound care, invested in by the U.S. Military, Wake Forest Institute for Regenerative Medicine is developing a technique to 3D print a cell-infused care gel directly onto burn injuries.

For more of the latest from 3D technology in medicine sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Register on our 3D printing jobs site here.

Featured image shows VTT’s electronic wound care device attached to the skin. Photo via VTT Technical Research Centre of Finland Ltd.