Viscosity is the enemy of 3D printing. It is the rate that a liquid deforms when placed on a flat surface, and materials that are pumped through printing heads, regardless of the size opening, are held hostage to it. The usefulness of both highly viscous materials like molten plastic, and materials with comparatively lower viscosity like paste, chocolate and silicone all have limits to the resolution that can be achieved using typical 3D printing extruders. But a developer of dosing technology has entered the 3D printing market with their technology and has seemingly managed to push past those resolution limits.

ViscoTec creates the technology that allows manufacturers to fill bottles of products like cosmetics and lotions at extremely rapid speeds. The secret to their technology is the “endless piston principle”, which they use to maintain and control the extrusion of materials with varying levels of viscosity with a high rate of accuracy. Their new 3D printing heads use the same technology to allow a greater amount of control over the flow of material, leading to highly detailed prints with materials like silicone and paste that typically have low resolution rates and low printing speeds.

The key is controlling the flow using an eccentrically, or off center, rotational piston inside of a printhead with opposing geometry. The geometry allows the flow of material to be controlled and when calibrated to a specific materials viscosity accurately predict the amount of material extruded. It can even reverse the flow of material, preventing drips and uneven layers of material.

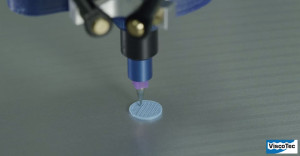

You can see how precise the printing resolution is in this video of the ViscoTec extruder printing with a silicone material:

The new printing heads and the companion software are compatible with virtually any FFF/FDM 3D printer on the market. They can create prints with a layer thickness of 0.2mm at rates of 1 ml/minute depending on the viscosity of the material.

ViscoTec’s printing heads are optimised for 3D printing materials with extremely low rates of viscosity, like silicones, UV-Curing adhesives, organic cell solutions, chocolate and pastes. It also has very interesting applications for bioprinting. You can see an example of what it can do with biological material in this video:

Currently the printing heads are not being sold individually but are being sold as industrial applications. That means that they are probably really expensive, so you won’t be able to install this on your MakerBot any time soon. But the technology is certain to be brought into the desktop 3D printer market eventually.