Researchers at the Massachusetts Institute of Technology (MIT) have developed a system to design and 3D print complex actuators.

The toolkit, presented in the study published in Science Advances, consists of multi-objective topology optimization software for design synthesis and multi-material drop-on-demand 3D printing for the fabrication of robotic actuators.

The system enables the manufacture of mechanisms “virtually impossible for humans to do by hand”, particularly in the aerospace sector, according to first author Subramanian Sundaram, a former PhD graduate student in the Computer Science and Artificial Intelligence Laboratory (CSAIL).

“Our ultimate goal is to automatically find an optimal design for any problem, and then use the output of our optimized design to fabricate it,” added Sundaram.

3D printed actuators

Actuators in the MIT study mechanically control robotic systems in response to electrical signals that transmit black-and-white images at different angles. Earlier this year, a team from the MIT Media Lab developed Cilllia, a computational method of 3D printing hair structures, which can be used as a passive actuator for moving objects.

The new actuator system from the university consists of soft and rigid polymers and a magnetic nanoparticle polymer composite that responds to a magnetic field. A topology optimizer is built to control the placement of the materials based on their properties and a generated voxel model. A custom 3D printer equipped with vats of the materials are connected to print heads with hundreds of nozzles that can be individually controlled to fabricate an actuator.

30μm sized droplets of the designated material is fired into its respective voxel location, which is then solidified layer by layer on a substrate. With this process, the MIT researchers 3D printed an actuator that portrays a Vincent van Gogh self portrait when laid flat. When tilted, it is activated, and displays famous Edward Munch painting “The Scream.”

‘Combinatorial explosion’

The system is based on a property library which randomly assigns different materials to different voxels. Typically during this process, the parameters are manually calculated to find an optimal design. A simulation is run to confirm the desired arrangement straight on and at an angle. Adding, removing, and shifting around brown magnetic voxels will change the actuator’s angle when a magnetic field is applied.

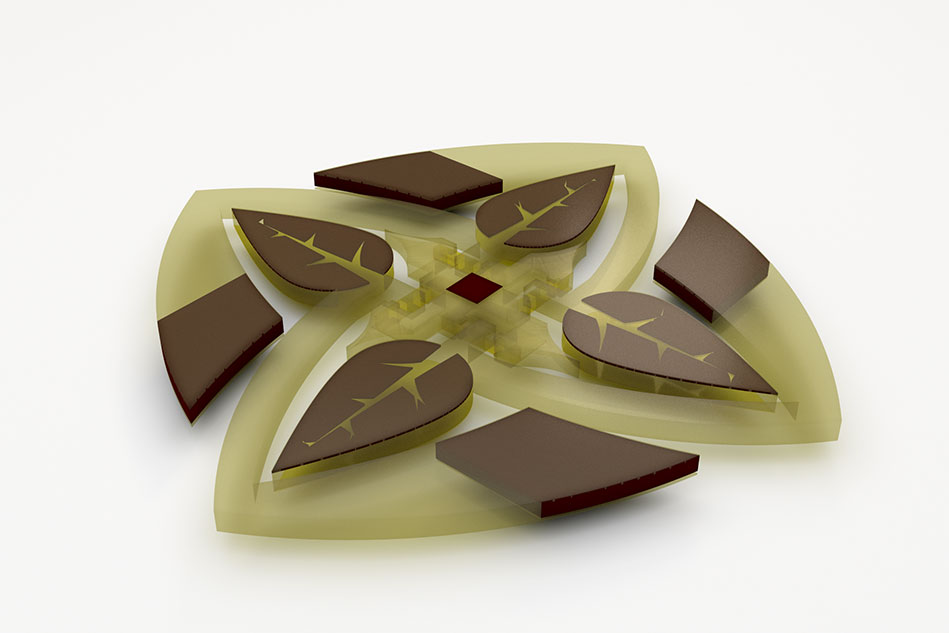

3D printed floating water lilies were also created with petals equipped with arrays of actuators and hinges. This allowed the petals to fold up in response to magnetic fields run through conductive fluids.

Sundaram noted that as a result of new multi-material 3D printing techniques, a design’s dimensionality becomes more complex. “What you’re left with is what’s called a ‘combinatorial explosion,’ where you essentially have so many combinations of materials and properties that you don’t have a chance to evaluate every combination to create an optimal structure.”

The researchers believe that this automated process could progress the design of larger structures, such as airplane wings. Presently, researchers have started breaking down airplane wings into smaller voxel-like blocks to optimize their designs for weight, lift, and other metrics.

“Topology optimization and 3D printing of multimaterial magnetic actuators and displays” is co-authored by Subramanian Sundaram, Melina Skouras, David S. Kim, Louise van den Heuvel, and Wojciech Matusik.

Want the latest 3D printing research? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for new opportunities in additive manufacturing? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows a novel lily with integrated 3D printed actuators. Photo via MIT/Subramanian Sundaram.