Advanced manufacturing service provider Vertex Manufacturing has installed an ElemX liquid metal 3D printing system from US printer and photocopier manufacturing Xerox to its Cincinnati facility.

With the addition of the new system, Vertex Manufacturing hopes to bolster its contract manufacturing services and provide aluminum 3D printing capabilities to its industrial customer base. In turn, Vertex has joined Xerox’s Elem Additive Solutions Manufacturing Partner Network in an important milestone for the printer firm.

“The relationship with Vertex enables our Elem Additive business to scale and support our customers better than before,” said Tali Roseman, Elem Additive General Manager and Vice President at Xerox.

“Between the two organizations, there are decades of experience in advanced manufacturing, so we are thrilled to push the limits of this technology together.”

Xerox’s 3D printing evolution

With an established background in 2D paper printing, Xerox had outlined its intention to enter the 3D printing sector as far back as 2016. Then, in 2018, the firm’s CEO John Visentin revealed Xerox was indeed “developing a roadmap to participate in 3D printing.”

The announcement was followed by the acquisition of 3D printer manufacturer Vader Systems and its liquid metal jet technology in 2019, and later that year Xerox made its Formnext debut with a significant presence at the show. ElemX is the name now given to Xerox’s metal 3D printing platform, first displayed by Vader Systems at IMTS in 2016.

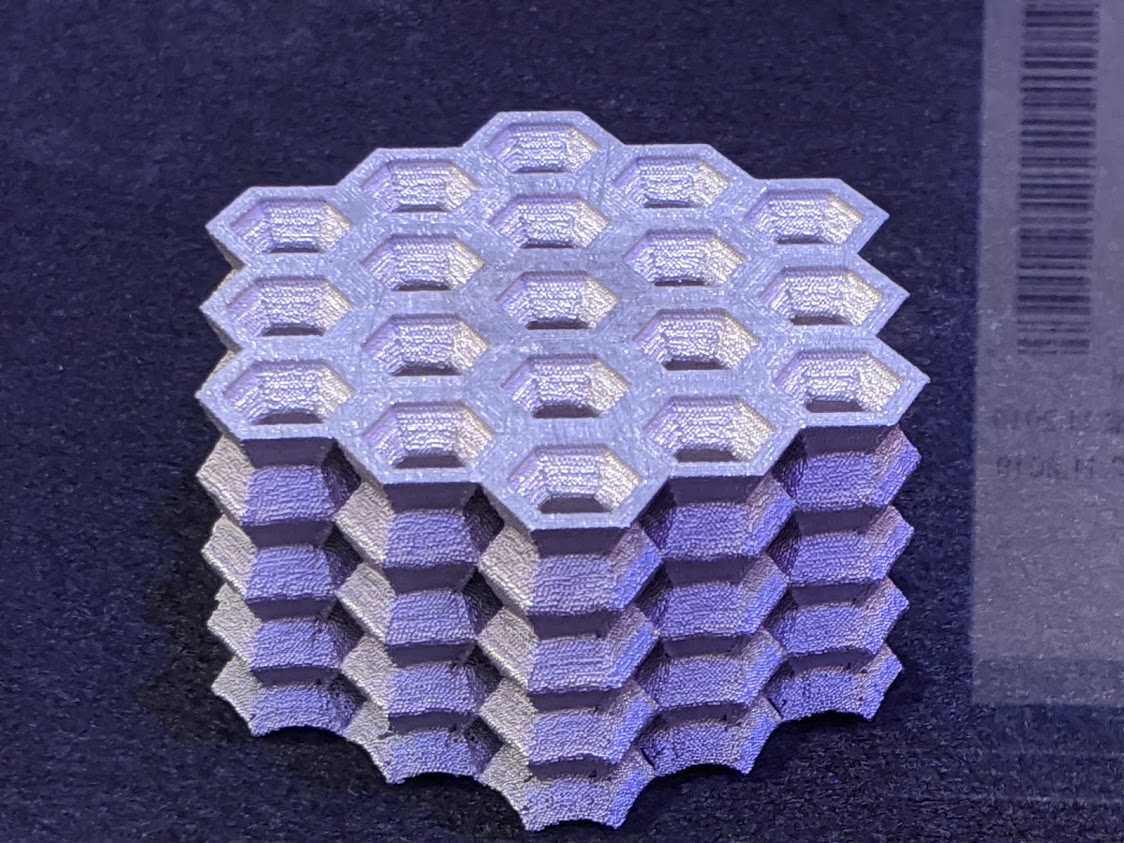

The ElemX 3D printing system uses off-the-shelf aluminum wire to fabricate production-grade parts at reportedly lower costs than traditional production methods. Parts printed with the technology also require minimal post-processing, with no additional depowdering, debinding, or sintering steps.

Updates and announcements around Xerox’s ElemX system have been fairly sparse since the system was commercially introduced in February 2021. The system was unveiled in an announcement revealing the US Naval Postgraduate School (NPS) had installed one of the systems on its university campus as part of a research partnership with the firm.

Through the deal, Xerox and the NPS are exploring the potential for liquid metal 3D printing to transform how the military supplies its deployed forces and provide greater supply chain flexibility.

Scaling Elem Additive

Xerox has now announced that one of its ElemX 3D printing systems will be added to Vertex Manufacturing’s Cincinnati facility to provide aluminum 3D printing capabilities to its customers.

Vertex, which was acquired by 3D printing service bureau PrinterPrezz in October last year, will bring the ElemX system under its roof to bolster its existing metal 3D printing capacity, which includes machines from GE’s Concept Laser and VELO3D.

“Our business is committed to delivering products and services that meet or exceed our customers’ quality and schedule requirements,” said Tim Warden, Vice President of Sales and Marketing at Vertex. “We decided to partner with Xerox because the ElemX technology gives is an added advantage to build parts faster and more reliably for our customers.”

Over the past year, Xerox says it has been growing its Elem Additive Solutions division, having recently opened its Additive Manufacturing Center of Excellence in North Carolina. The new contract agreement with Vertex is another important milestone for the firm.

According to Xerox, the ElemX is particularly suited to the reliable production of spares, repairs, and low-volume production aluminum parts, while offering improved safety and simplicity benefits.

“ElemX takes all the benefits of 3D printing and makes it easier than ever before for manufacturers to use metal additive manufacturing,” added Rosman.

“This is the next step in our journey, and we plan to continue advancing our vision for more resilient supply chains in 2022 working with partners like Vertex.”

The past year has also seen Xerox lead a seed funding round for additive manufacturing software developer CASTOR, and ink a multi-year software deal with cloud and computing software firm Oracle to allow its new businesses to launch and monetize their services more quickly.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Xerox ElemX liquid metal 3D printer. Photo via Xerox.