Optics manufacturer Vector Photonics has announced that it will be leading BLOODLINE, a £1.5M international consortium project aimed at developing the company’s proprietary PCSEL (photonic crystal surface emitting semiconductor laser) chips for metal 3D printing.

The University of Glasgow spin-out will be joined by an unnamed Japanese semiconductor manufacturer and the UK’s Compound Semiconductor Applications (CSA) Catapult, who will be responsible for chip reliability testing. The Innovate UK-funded project will also involve a leading Japanese 3D printer manufacturer, who will be providing product assessment and an eventual route to market via system integration.

Dr. Richard Taylor, CTO of Vector Photonics, states, “3D metal laser printers hold metal powder in a ‘powder bed’ at just below melting point. Currently, CO2 or fibre lasers, directed by mirrors, scan over the surface of the powder, melting the metal powder to the layer below, in what is termed Selective Laser Melting (SLM). Vector Photonics’ PCSEL technology will revolutionise the SLM process.”

Vector Photonics’ PCSEL technology

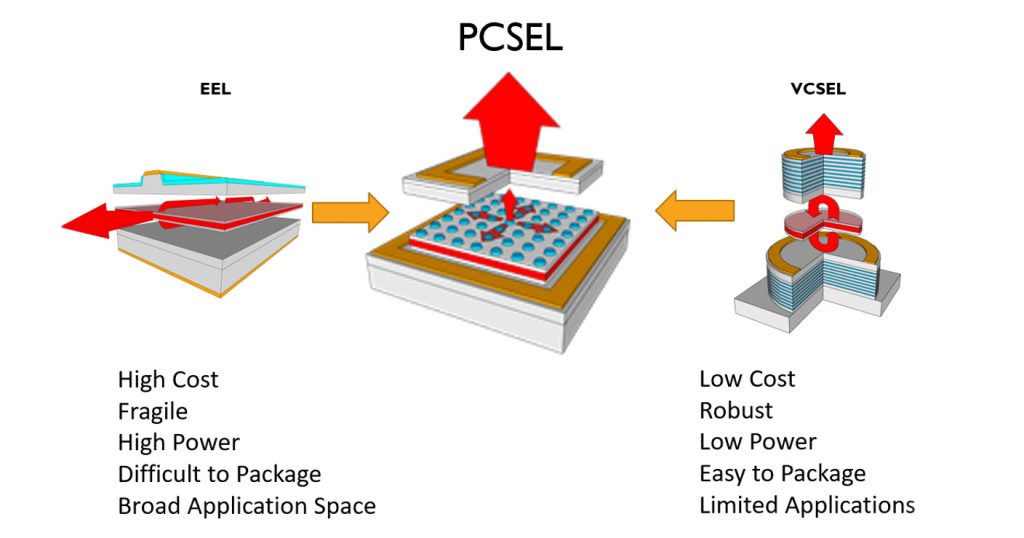

Dubbed the ‘future of laser production’, PCSELs are an entirely new class of semiconductor laser. They are characterized by their 2D grating structure, which enables them to scatter light both linearly and orthogonally. According to Vector, this makes PCSELs the only laser type to feature in-plane feedback and out-of-plane light emission.

This out-of-plane, orthogonal surface emission comes with its assembly cost advantages, as it makes the lasers easy to package to integrate into electronics and PCBs – historic applications of the technology. The 2D grating structure also provides a higher data rate, broader wavelength range, and improved power performance when compared to similar EELs (edge emitting lasers) and VCSELs (vertical cavity surface emitting lasers).

Neil Martin, CEO of Vector Photonics, adds, “Our PCSELs produce the speed performance of EELs and VCSELs, whilst their tested and packaged cost is 50% that of EELs and they deliver over 10x the power of VCSELs.”

PCSELs for powder bed fusion

While PCSELs have been used extensively in R&D and laboratory environments since their invention, Vector is now transferring the design over to the industrial space, in high-volume metal 3D printing.

The unique combination of increased power and improved reliability makes the lasers great for powder bed fusion. BLOODLINE will involve scaling up the PCSEL arrays and removing the mirrors in the printers’ scanning assemblies altogether, meaning an entirely solid-state laser system will be offered. The company believes this will result in a greater manufacturing efficiency and higher resolution parts, as well as reduced finishing overheads and faster print speeds.

Taylor concludes, “We believe that PCSELs will enable an entirely new class of next generation, metal printers and contribute to even greater market growth.”

With the incredible market growth industrial 3D printing has already seen, innovations in metal 3D printing systems are inevitable. 3D printer OEM Freemelt recently unveiled a new patent-pending method of preheating the powder bed in electron beam PBF 3D printers. Dubbed ProHeat, the method uses electromagnetic radiation to sinter the powder layers smoothly and evenly.

Elsewhere, blue laser specialist NUBURU recently added seven new patents to its intellectual property portfolio. The company’s innovative lasers are designed to optimize the performance of DED-based machines by enabling copper to be clad to other copper surfaces, while significantly increasing print speeds.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Selective Laser Melting (SLM), a type of powder bed fusion 3D printing. Photo via K2M.