Defects in 3D printed parts can cause tremendous failures in a finished component. Luckily, new research from Vanderbilt University, Tennessee, has gleaned a new way of detecting faults.

By introducing gold nanoparticles into the 3D printer material, researchers can now quickly scan parts to help predict failures before they happen.

“There are tremendous possibilities for what we can do with this technology,” explains Kane Jennings, co-author of the study and Vanderbilt professor of chemical and biomolecular engineering.

“We have demonstrated the 3D printed parts can be self-reporting. They self-report defects. We’re looking now at the possibility to do even more with these smart materials.”

The valuable filament

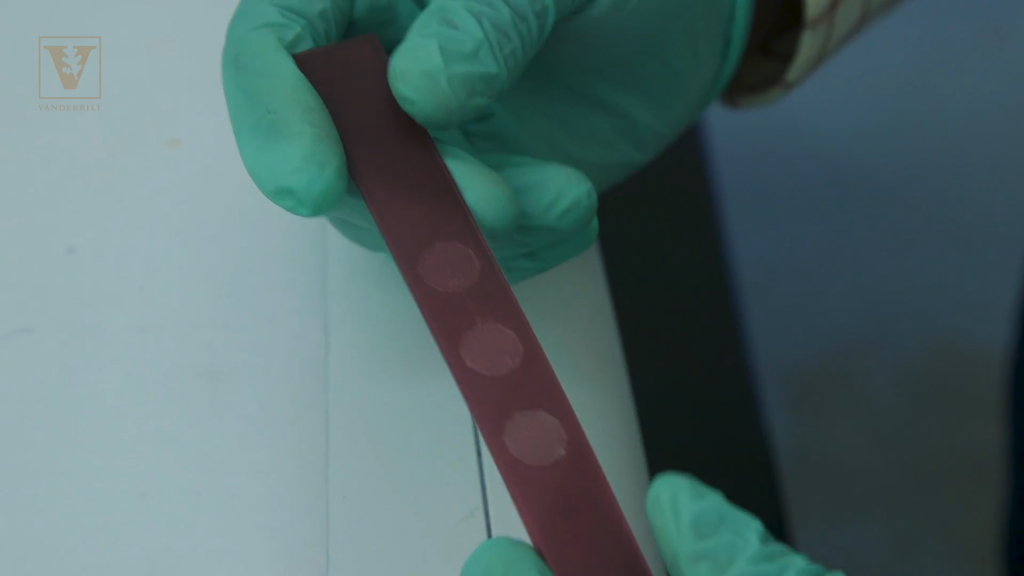

In the Vanderbilt study, gold nanoparticles are dissolved within a polymer. When this dries it is shredded, then melted a second time so it can be extruded as a filament. The process ensures that gold particles run all the way through the material.

The filament is used to 3D print an object as normal on a desktop FFF/FDM 3D printer. Then afterwards it is scanned using ultraviolet-visible (UV-Vis) spectroscopy.

A non-invasive process, the UV-Vis spectrophotometer records reflections from the gold nano particle content. Based on the information received in this reading, the scientific team can then make an informed decision about potential faults in the part.

How does it work?

Cole Brubaker, civil engineering graduate student at Vanderbilt, is lead author of the study. Explaining how the process works, Brubaker says, “We’re using the absorbance properties of the embedded gold nanoparticles. You just scan light across the surface of the sample and see where the absorbance decreases inside, signaling a defect in that material.”

As a result, “A defect can be found with one single nondestructive measurement. It’s very quick. It takes just a matter of seconds.”

Going for gold

The study could be an important step forward for the classification and qualification of 3D printed parts within the wider industry.

At present, in metal additive systems, high-end sensors and intelligent software is applied to predict or detect potential flaws in the parts.

Brubaker adds, “We are able to inspect and detect defects that aren’t visible to the naked eye, using the optical properties of embedded gold nanoparticles. That’s a very critical step – being able to say ‘We have a defect. It’s right here.”

The paper supporting these findings, “Nondestructive Evaluation and Detection of Defects in 3D Printed Materials Using the Optical Properties of Gold Nanoparticles“, can be found online in ACS Applied Nano Materials. It is co-authored by Cole D. Brubaker, Michael A. Davies, James R. McBride, Sandra J. Rosenthal, G. Kane Jennings and Douglas E. Adams.

For all of the latest 3D printing research subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Seeking your chance to get involved in a new project? Sign up to 3D Printing Jobs now, or post a new opportunity.

Featured image shows gold glitter on a bauble. Photo by Flickr user Sam-Cat