3D Printing Industry has followed the progress of Vader Systems since IMTS 2016 when in Chicago that year, the Buffalo NY based company unveiled their first commercial liquid jetting additive manufacturing system.

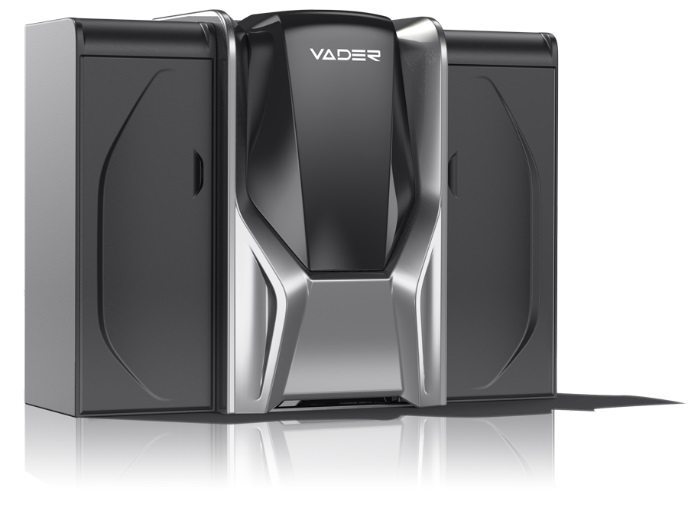

Now Vader Systems has announced the first commercial sale of its Mk1 3D printer to BECKER CAD-CAM-CAST (Becker), a tier one supplier of engineered aluminum automotive components.

Vader Systems holds the patent on MagnetoJet, this technology melts metal wire and then uses electromagnetic propulsion to “produce on-demand, precision droplets of molten aluminum.” The company says that MagnetoJet can be used to 3D print parts, “at unprecedented rates and with reduced operational costs in comparison to powder bed processes.”

A deposition rate of 1 lb per hour based on 500 micron droplet size is cited on the company’s website. The Mk1 has a build volume of 300 mm x 300 mm x 300 mm and uses Argon as a shield gas.

Ten-fold decrease in cost

Ten-fold decrease in cost

MagnetoJet technology uses a standard aluminum wire rather than materials specifically designed for 3D printing. According to the company the use of wire feedstock means that a ten-fold decrease in material cost is possible. Material options are currently limited to 4043 aluminum, with 6061 and 7075 aluminum alloys, copper, and bronze under development.

Zachary Vader, Chief Innovation Officer and Co-founder of Vader Systems, and inventor of MagnetoJet, said, “An important part of my vision in developing this technology was to impact the automotive industry. I’m thrilled that a company of Becker’s caliber has recognized this potential and is choosing to integrate the Mk1 into their manufacturing process.”

Becker’s CEO Michael Becker said, “VADER’S printing technology is a game changer for cost-effective, low-volume production of aluminum components. It aligns with our goal to deliver shorter lead times and higher performance for our customers.”

Becker plans additional purchases

The Mk1 system will be integrated into Becker’s manufacturing process at the company’s new Wixom, Michigan, plant in the first quarter of 2018. Becker plans to add a second system at their Germany headquarters in late 2018.

Visitors to formnext can learn more about MagnetoJet technology at both the Becker (3.0-A44) and Siemens booths (3.0-E68) in Frankfurt, Germany, from November 14-17.

For more announcements ahead of upcoming shows, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.