Researchers from the University of Delaware have developed novel additive manufactured Luneburg lenses with the ability to communicate at 5G frequencies.

Using FDM 3D printing, the team produced several microscopic antennas with flat surfaces, enabling them to be added to electronics, sensors or even mobile phones. Now working with the U.S. Army, the scientists are developing both defense-related robotics and civilian aerospace applications, for their additive transmitting devices.

“This lens is a very inexpensive, effective way of steering communication signals in a particular direction, it will be particularly useful with 5G,” said Professor Mark Mirotznik, who led the research. “We think our lens might have applications for those sorts of ‘edge-of-the network’ kind of things because they are inexpensive, yet really robust.”

Going additive with antennas

Wireless communications systems have become increasingly relevant to our daily lives, as the technology is often used within the radars and satellites that connect everyday smart devices. To fulfil this vital role, these antennas need to be high-gain, wide-angle, agile and capable of relaying multiband signals.

At present, steerable phased array antennas are used within satellites to achieve this, but they can be expensive, complex and power-consuming technologies. Gradient Index (or GRIN) Luneburg lenses have often been touted as an alternative, as their spherical graded structures allow them to relay multiple beams at once.

Despite the attractive properties of GRIN devices, their spherical geometries have made them difficult to integrate into standard antenna arrays. Using a Transformation Optics (TO) process, however, it’s possible to convert Luneburg lenses into planar surfaces that are more compatible with conventional satellites.

Although TO has been deployed somewhat successfully in this area, progress has been hampered by the presence of reflections in the lens’ feed. To combat this, the team theorized that using 3D printing, it would be possible to add an anti-reflective (AR) layer, yielding a Luneburg device with multi-frequency capabilities.

3D printing the Luneburg lenses

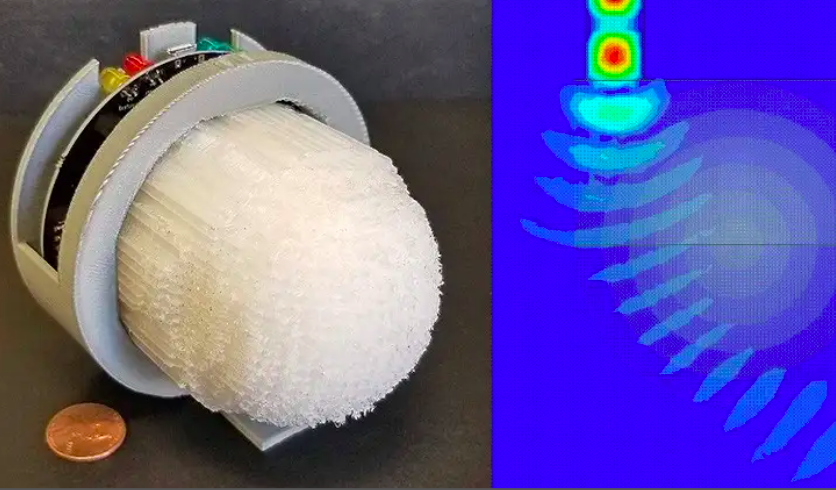

In order to test their hypothesis, the scientists 3D printed an AR layer onto an existing lens’ planar excitation surface, and configured it to operate in the Ka-band (26–40 GHz). The electromagnetic properties of the prototype were then tested and compared to simulations, as well as the performance of existing GRIN devices.

During evaluations, the team’s upgraded antenna design was able to mitigate the reflections seen in existing lenses over the ka-bandwidth. The prototype also narrowed the lens’ half-power, and when compared to computer projections, it showed an aperture efficiency of more than 60% at most of the feed locations.

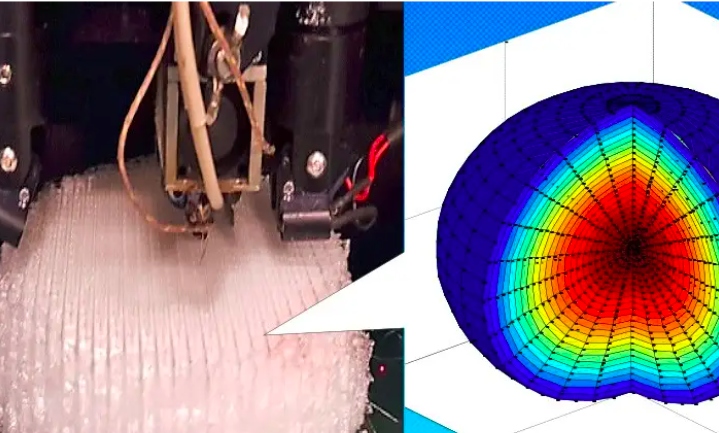

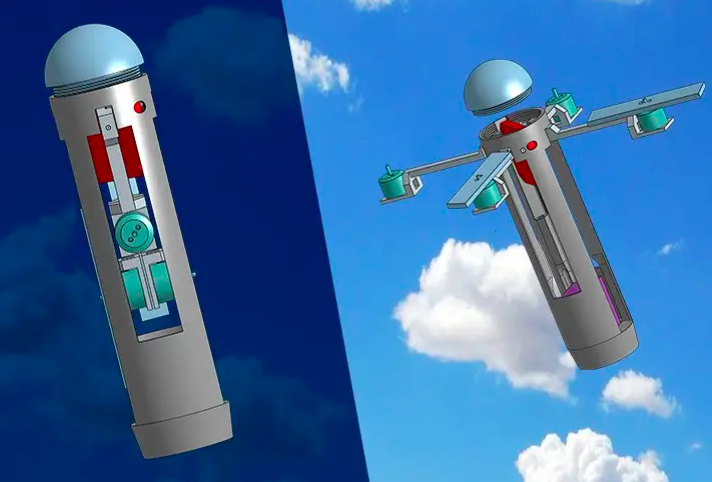

The researchers initially conceded that their AR layer sometimes limits the device’s scanning angle, but they’ve since optimized its performance. Working with DeLUX AM, a startup that Mirotznik co-founded, the team has also identified various novel lens applications, including embedding it within a 3D printed ‘quadcopter.’

The scientists have now been contracted by the U.S. Department of Defense to build a robot that’s capable of removing itself from a conveyor, and immediately setting off. It appears ambitious, but the team has already printed a lens-integrated device that moves itself from the build plate, showing the technology’s overall potential.

Developing enhanced additive antennas

The cost and design flexibility benefits of adopting 3D printing have increasingly enabled researchers to manufacture 5G antennas with upgraded relaying capabilities.

UK-based researchers have examined the merits of 3D printing Multiple Input Multiple Output (MIMO) antennas for 5G systems. The proposed ‘MIMOs’ could be capable of delivering beams in multiple directions, providing continuous, real-time coverage without the need for phase shifters.

Another team from the University of Delaware has deployed an XJet Carmel 1400 3D printer to fabricate novel 5G antennas. Using Passive Beam Steering algorithms, the scientists were able to print lenses with a complex structure, small channels and optimized material properties.

Elsewhere, scientists at the University of Birmingham have deployed precision 3D printing to fabricate circuitry for 5G antennas. Developed as part of a military-led project, the devices could also have civilian mapping and car radar applications.

The researchers’ findings are detailed in their paper titled “High gain, wide-angle QCTO-enabled modified Luneburg lens antenna with broadband anti-reflective layer,” which was co-authored by Soumitra Biswas and Mark Mirotznik.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows one of the Delaware team’s 3D printed experimental communications devices. Photo via the University of Delaware.