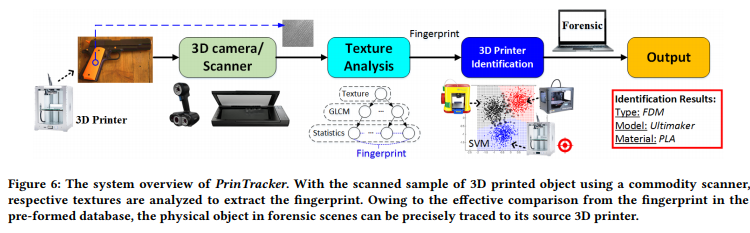

PrinTracker is a 3D printer identification system recently developed by researchers at the University at Buffalo in New York. With this system, 3D printed objects can be tracked back to the machine that created them. Its purpose is to help law enforcers crack down on the potential unethical and criminal use of 3D printers.

Counterfeiting, IP infringement and even the row over 3D printed guns are put in their place by this new system.

3D printing and security

Security procedures for 3D printing are in experimentation across the industry for the potential dangers their pose to development sectors in defense, aerospace, automotive and beyond. Such features span from blockchain technology for protecting master files; through to secure supply chain monitoring; and embedded QR codes to help ensure the 3D printed part is authentic.

PrinTracker’s niche within this area is the ability to recognize source 3D printer based on the unique way that they deposit material. As with human fingerprints however, this system requires a database, or at least a suspect machine for verification.

Infill fingerprints

The PrinTracker research is based on the principle that while a certain brand of 3D printer may all be manufactured in the same way, no two machines produced en masse will be identical. Wenyao Xu, associate professor of computer science and engineering at the University at Buffalo and lead author on the study detailing PrinTracker’s capabilities, explains “3D printers are built to be the same. But there are slight variations in their hardware created during the manufacturing process that lead to unique, inevitable and unchangeable patterns in every object they print.”

This study found that the infill patterns of 3D printed objects varied in accuracy between 5 and 10 % of the initial CAD file. These variations were tracked on a layer by layer and machine by machine basis using scanning and texture analysis. The result was a unique calling card or fingerprint database containing each 3D printer.

Identified with 99.8% accuracy

In the PrinTracker experimental section, the researchers tracked and tested the infill variations of 14 desktop 3D printers:

– 3 x Ultimaker 2 Go

– 1 x Ultimaker 2 Extended

– 2 x MakerBot Replicator

– 2 x MakerBot Replicator 2X

– 2 x XYZ Printing Da Vainci Mini Maker

– 4 x Formlabs Form 1+

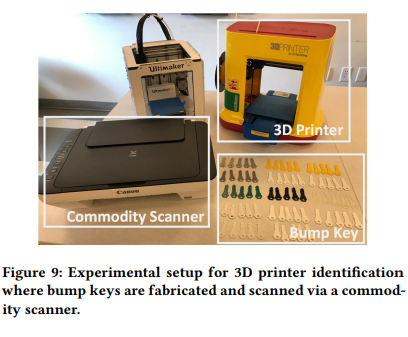

Each of these 3D printers were tasked with creating a set of five door keys. After 3D printing, these keys are scanned by a regular desktop scanner 50 times and the images are fed into an algorithm, trained to identify the signatures of each machine.

According to results, PrinTracker matched the key to respective 3D printers with 99.8%. Furthemore, when the keys were damaged in attempt to obscure the data, PrinTracker successfully operated with 92% accuracy.

Further reading

Though this operation would be ineffective without the “offending” 3D printer, it does present some interesting food for thought on the topic of security.

Discussing the potential applications of the PrinTracker system, Xu explains, “3D printing has many wonderful uses, but it’s also a counterfeiter’s dream.” Furthermore, if the impracticality of 3D printed guns is to be ignored, “[…] it has the potential to make firearms more readily available to people who are not allowed to possess them.”

With this study, Xu believes that, “We’ve demonstrated that PrinTracker is an effective, robust and reliable way that law enforcement agencies, as well as businesses concerned about intellectual property, can trace the origin of 3D printed goods.”

“PrinTracker: Fingerprinting 3D Printers using Commodity

Scanners” is published in the Proceedings of the 2018 ACM SIGSAC Conference on Computer and Communications Security. The paper is co-authored by Zhengxiong Li, Aditya Singh Rathore, Chen Song, Sheng Wei, Yanzhi Wang and Wenyao Xu.

For all the latest additive manufacturing research subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in academia? Create a free profile on 3D Printing Jobs, or advertise (for free) to find expertise in your area.

Featured image shows a 3D printer’s fingerprint. Image via Wenyao Xu/University at Buffalo.