U.S. railroad company Union Pacific (UP) has revealed an innovative use of 3D printing to improve locomotive operations.

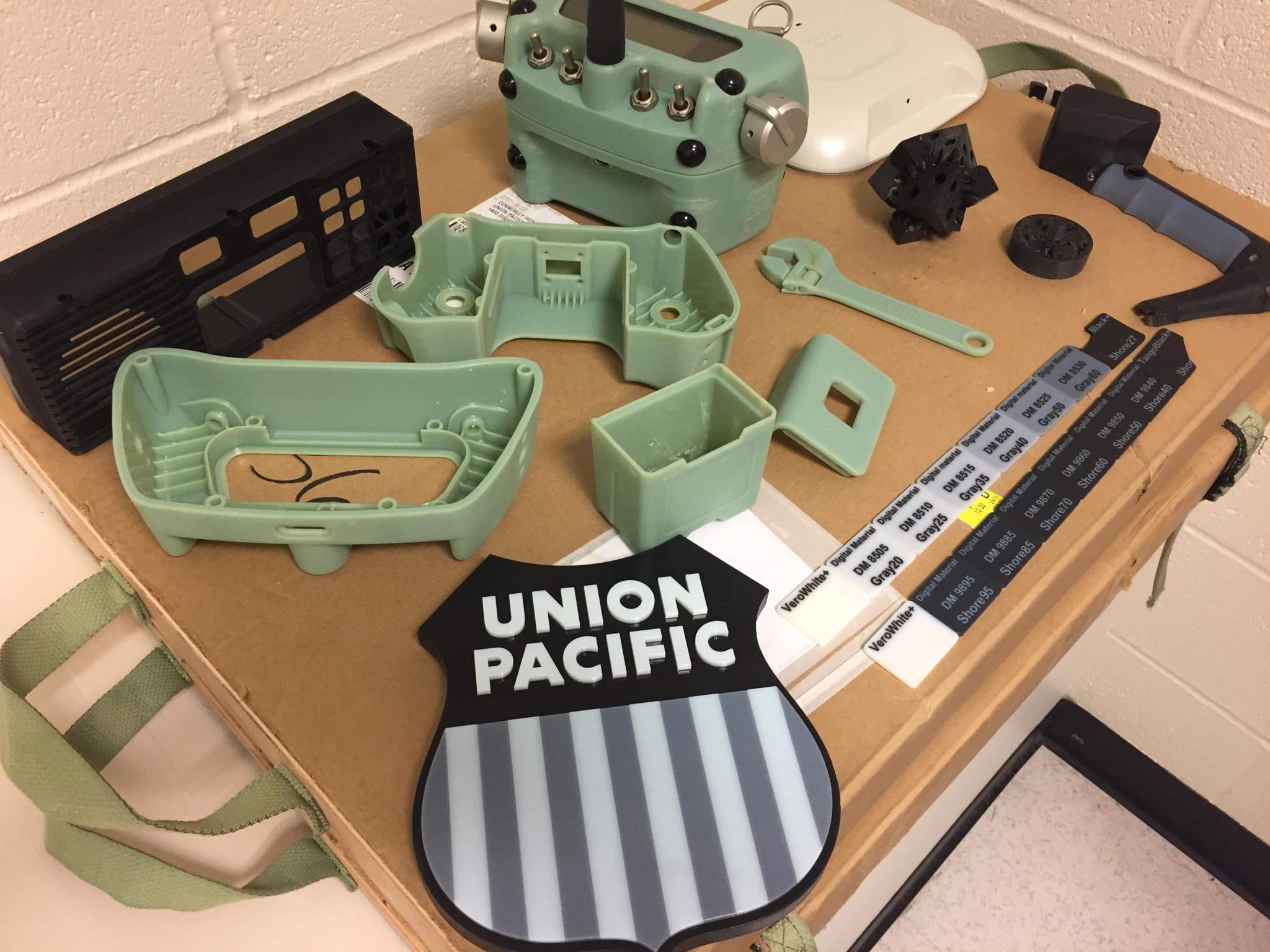

The company’s headquarters in Omaha, Nebraska currently houses a Stratasys Connex 350. The 3D printer allows the railroad operators to rapidly iterate designs and these have advanced the way Union Pacific operates.

According to UP, the 3D printer supports the railroad company’s use of machine vision technology as well as creating prototype equipment tracking devices.

Machine vision

Machine vision refers to the use of imagery for automatic inspection or analysis. Union Pacific was previously required to manually inspect its locomotives as they entered or left a rail yard, but have recently turned to an autonomous machine vision system. As a result, the engineers have sped up the process by using imaging areas which are able to create three-dimensional models of train carriages while they travel at high-speeds. Union Pacific has tinkered with the system by 3D printing a number of different parts. These include a critical 3D printed air knife which is used to keep the laser cool and free from debris. The part will later be mass-produced having proved its compatibility.

Machine vision has been implemented elsewhere in the 3D printing industry, as engineers at Carnegie Mellon University developed a computer imaging system to autonomously classify powders used for 3D printing metal.

Automatic equipment identification (AEI)

Union Pacific engineers have also 3D printed remote control devices to track rail equipment and ensure rail cars are assembled in the correct order. The prototype designs validate the feasibility of the user-friendly AEI devices before mass production.

Speaking about the use of 3D printing, UP’s Senior System Engineer, Royce Connerley explains,

We can make design tweaks and have a new version ready within hours, plus the prototype never leaves UP. Additionally, it ensures a complete design before we move into expensive tooling or long lead times for molded parts.

Transport industry

The transport industry holds particular promise for 3D printing for the speed of its production. Currently, the UP 3D printer in Nebraska is used for experimentation and prototyping. However, European railway company Deutsche Bahn is beginning to implement the technology to create spare parts and German automotive company Daimler is exploring the ability to 3D print low volume components for it’s bus fleet.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows a Locomotive passing through the Machine Vision point in Beck, Nebraska. Photo via Union Pacific.