From the Proto Space FabLab in Utrecht to becoming the company that is leading the way to personal manufacturing: it only took little over four years and two 3D printer models for Ultimaker to become a prime example of true open source mentality combined with a profitable, rapidly growing business.

It all began when two of the company’s co-founders, Martijn Elserman and Erik de Bruijn, found out about RepRap 3D printers. After some tinkering they were able to assemble ten of them but only two of them worked, Sander van Geelen, who manages the lively Ultimaker community, tells me. “So they implemented some improvements and shared their ideas in workshops. They finalized it and published it open source.”

They thus decided to set up a fully fledged company and factory. They chose Gelsen….. because it was roughly in the centre from the three towns the founders lived in and that is where I found myself during my visit. The place is just right for a small open source 3D printing company: it used to be a school and it is located right across the highway from the train station, with not much else around but green fields. Sander joined the founding team in December of 2011. Since then the company doubled and has since tripled in size. “With the Ultimaker Original it was rapidly growing but still manageable,” Sander says, “Now it is still, just about, manageable but sometimes I see people around that I don’t even know”.

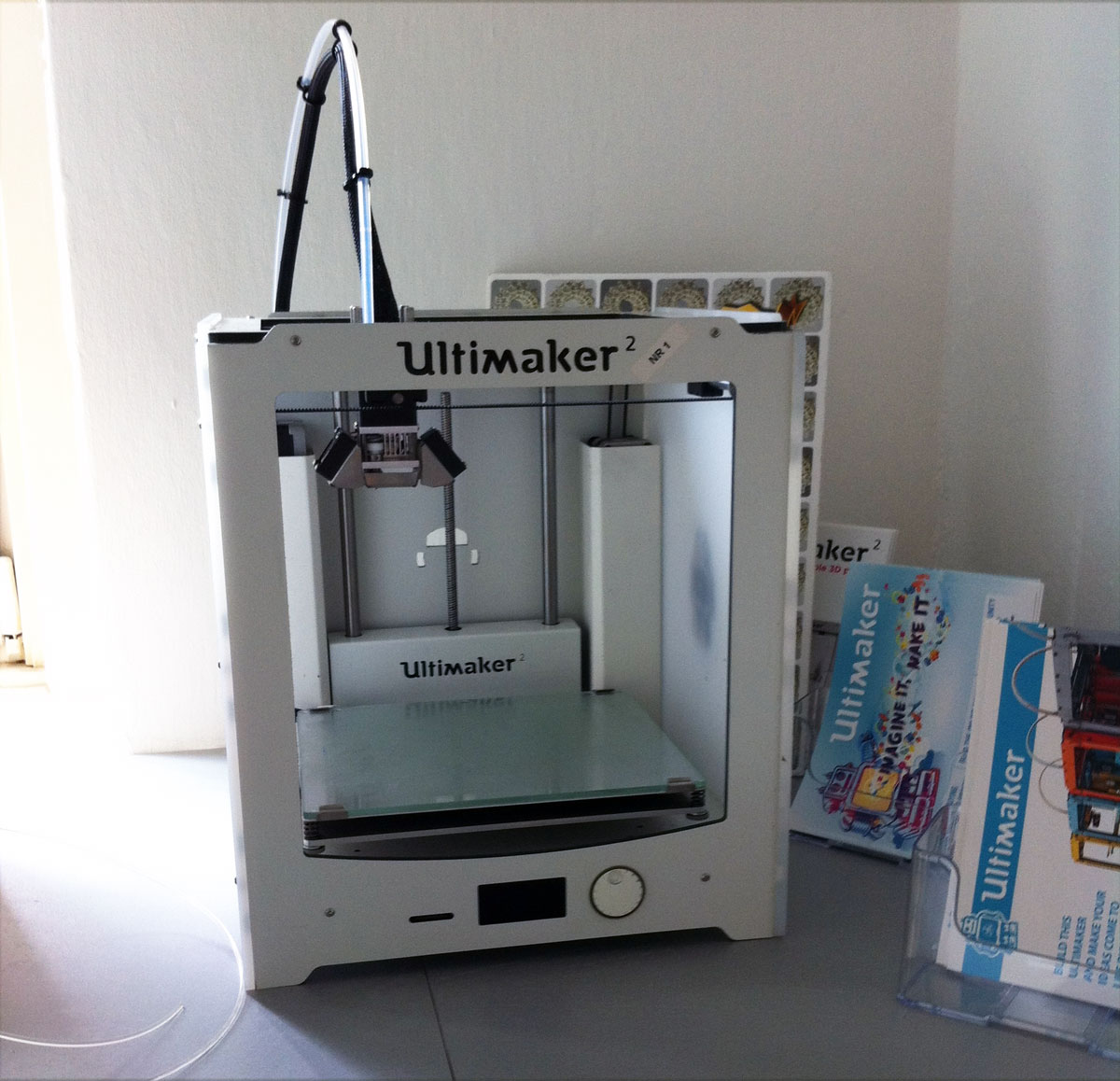

Since the Ultimaker 2 launch at the end of 2013 there were lead times of up to 10 weeks. Now the situation is under control and the lead time is down to just 10 days. “We had to take our time to train the employees on how to assemble the machines correctly, they had to learn all the tricks. Now, however, we are up to par and are starting to establish solid relationships with distributors around the world”.

While the Netherlands remains their first market, demand for their machine is growing in Germany, the UK and the Scandinavian nations as well. They signed distribution deals with iMakr, iGo3D, Ultimaker GB and two resellers in the United States: Dynamism and Maker Shed, along with Maker Shop in France. “We want to stick to focused distributors, and we explicitly look for young eager guys like us instead of more established brands,” Sander explains. “We want them to share our enthusiasm and not simply shove boxes around. They have to be able to establish a personal relationship with their customers.”

Ultimaker last available sales numbers are relative to a few months ago and see the company as the probable market leader in Europe, while trailing behind MakerBot in the US. All that is probably going to change soon, as the company is focusing more on the other side of the Atlantic Ocean with its new distributors.

“We started a couple months apart form MakerBot and in the beginning we were both moving in the same direction”, Sander reveals. “Then they collected a large sum of money from investors and that led to the sale to Stratasys.” I pointed out that MakerBot’s focus now is to make the new Replicators as “plug and play” as possible. Sander does not think that is the way forward for Ultimaker. “In general the more plug and play a system is the more walls you have to raise in terms of versatility. I think there is a fine balance between making a 3D printer reliable and making it customizable while letting people choose their own ideal settings. People should not be afraid to play with it and learn from their mistakes.”

People “experimenting, learning and sharing their feedback with the company is exactly what Utlimaker wants. They realize that what they don’t earn form closing the platform and selling materials or software they can easily make up in R&D contributions. That does not mean that all ideas coming from the community are implemented – only the most feasible ones – but it does mean that they are taken into consideration. Along with the intensive R&D done inside the company.

“We have two internal R&D departments. One is focusing mostly on the current Ultimaker technologies”, Sander says, revealing it is based right upstairs from where we are sitting, although the thought of letting me visit it does not cross his mind. “They have been working on the dual extrusion systems for the Ultimaker 2 and the heated bed for the Original. The team is also studying possible CAD and 3D scanning applications. The other is new: we called it Ultilabs and we established it when we released the Ultimaker 2. It has all three co-founders working within it and it is meant to be a creative space to experiment with a broader view and think outside of the box, mixing technologies”.

The super successful slicing software, Cura, is the brainchild of David Braam, who also joined the company upon receiving assurances that the software would remain strictly open source, while Erik also focuses on the Youmagine network, Ultimaker’s answer to Makerbot’s Thingiverse. It was also launched together with the Ultimaker 2 and, like everything else around here, has been growing at breakneck speed.

“It is a big platform and every day so many files are uploaded that we cannot keep track of them,” Sander admits. “We want to transform it into a social platform open to different technologies where users can post a project and source a team of makers to help with it. Once the solution has been found everyone in the community will be able to benefit from it and, who knows, it might even become the base for the next great and profitable open source project.”