Three new Lubrizol ESTANE 3D thermoplastic polyurethane (TPU) materials for fused filament fabrication (FFF) 3D printing are now available on the Ultimaker marketplace.

Lubrizol’s ESTANE 3D TPU F94A-055 OR HH PL, 3DP TPU 98A, and 3DP TPU F70D thermoplastics have been added to the free digital platform. The filaments are designed to address Ultimaker customers’ demands for plastics that can be used in FFF applications for industrial jigs and fixtures, prototypes, end-use parts, and flexible parts such as orthopaedic insoles.

“Lubrizol’s grades open the door for a great deal of possibilities for end-users printing with TPU; varying from outdoor parts with cold flexibility, to parts that require long-term heat performance.” said Bart van As, Materials Product Manager at Ultimaker. “Filaments made from Lubrizol’s ESTANE 3D TPU are among the softest and most flexible materials that can be printed on Ultimaker 3D printers.”

Ultimaker’s 3D printing marketplace

Dutch 3D printer manufacturer Ultimaker operates a digital marketplace via the Ultimaker Cura application which enables raw materials suppliers to upload profiles that are compatible with Ultimaker printers. According to the company, its award winning open source software, has more than 500,000 unique users each month, and processes 1.4 million print jobs per week.

The online application was launched at TCT 2017 to support the increased adoption of its 3D printers by professional designers, engineers, researchers, and manufacturers. Since then, the service has been enhanced by the additions of other material manufacturers such as Essentium, eSUN and Polymaker, who joined the company’s Material Alliance Programme in 2019.

Following the incorporation of Lubrizol’s TPU grade resins, the platform now supports 157 3D printing materials for a wide range of applications, which allows customers to avoid manual setup when using third-party materials.

Lubrizol’s advances in 3D printing

Lubrizol, an Ohio-based chemicals and materials company, operates more than 100 manufacturing facilities and offices around the world, and has approximately 8,800 employees. Since being founded in 1928, the company has become a provider of specialty chemicals for the transportation, industrial and consumer markets, and its products include additives such as engine oils, industrial lubricants, gasoline and diesel fuel.

In recent years, Lubrizol has attempted to make its materials more readily available in the 3D printing market, and the company joined HP’s Open Materials platform in 2017. Under the agreement, Lubrizol is not only able to access HP’s Open Materials and Applications Lab and its research tools, but it can develop materials under the HP brand.

The company continued to advance within the 3D printing industry by announcing a partnership with Chinese 3D printer manufacturer Farsoon Technologies at Formnext in 2019. The deal saw Lubrizol broaden the reach of its TPU powders.

Lubrizol’s ESTANE 3D TPU M95A powder passed skin sensitization and cytotoxicity tests in April 2020. The successful testing of the materials, which were produced using HP Multi Jet Fusion (MJF) technology, meant they could be used to 3D print products for end-use applications requiring contact with skin, such as footwear, prosthetic devices, and wearables.

The ESTANE range of TPU resins

In 2018, the company launched its first three 3D printing materials under the ESTANE imprint: the Estane ETE (Easy-to-extrude) TPU, Estane 58000 TPU, and the Estane MVT (Moisture Vapor Transmission) TPU. These soft, flexible to hard, and rigid grades of 3D printable materials, were followed later that year by the launch of Estane TRX TPU and BounCell-X, which were designed for the footwear market.

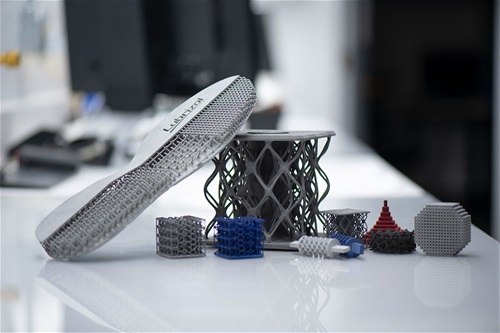

The company’s ESTANE range has been engineered to meet high-performance demands across a variety of applications from footwear to consumer and industrial products. Its portfolio of TPU resins provide 3D designers with polymers that enable thin part walls, enhanced layer-to-layer adhesion and consistent 3D printing of soft and flexible materials.

Now Lubrizol’s three latest ESTANE 3D printing materials have been added to Ultimaker’s digital platform. The 3D TPU F94A-055 OR HH PL filament is reported to provide high-heat long-term stability, whereas 3DP TPU F70D is useful for parts that are prone to rough handling due to its flexibility and good all-around mechanical properties. 3DP TPU 98A on the other hand, offers enhanced abrasion and chemical resistance, impact resistance and extrudes consistently making it easy to print with, according to the company.

“We’re very committed to making TPU materials with easy to process and consistent properties available via the Ultimaker Material Alliance Program, to provide long-term and sustainable solutions to all the end-users,” said David Pascual, Lubrizol’s Global 3DP Marketing Manager. “By focusing on differentiation, our goal is to attract new applications and help increase adoption of Ultimaker 3D printers.”

Recently released FFF 3D printing materials

FFF is one of the most widely-used techniques in 3D printing, and new thermoplastics are continually launched with the aim of creating products with enhanced features.

German specialty chemicals company Evonik introduced its Vestakeep i4 3DF implant grade polyether ether ketone (PEEK) filament in May 2020. The new material allows for the production of 3D plastic surgical implants using FFF 3D printing.

Polish 3D printing filament manufacturer Spectrum Filaments launched its ABS Medical and PETG FX120 materials in April 2020. Intended for use in medical and engineering applications, the flexible resin displays high-temperature resistance.

Essentium Inc., the Texas-based 3D printer manufacturer, announced a partnership with the chemical specialists LEHVOSS Group to develop high-performance materials for additive manufacturing in March 2020. The deal will see a line of PEEK and High-Temperature Nylon (HTN) filaments created specifically for production-level extrusion-based 3D printing processes.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a range of products that can be 3D printed using Lubrizol’s ESTANE filaments. Photo via Lubrizol.