Bioprinting with tissues… It’s something that just a few years ago would be an outrageous idea, but now, it’s becoming more and more of a reality. Last year, one Wake Forest professor, Dr. James Yoo, said with confidence that these bioprinted tissues can be implanted into human patients within a 10 year timeframe. Now, researchers from the University of British Columbia have just announced the development of a new chemical compound that stands to make bioprinting tissues safer and more affordable.

The chemical compound is a new type of biological ink used in the 3D printing of tissue, which is able to function without the use of UV light systems, using a much safer and more conventional light source instead. In fact, the bioink could create biological tissue using an everyday light projector.

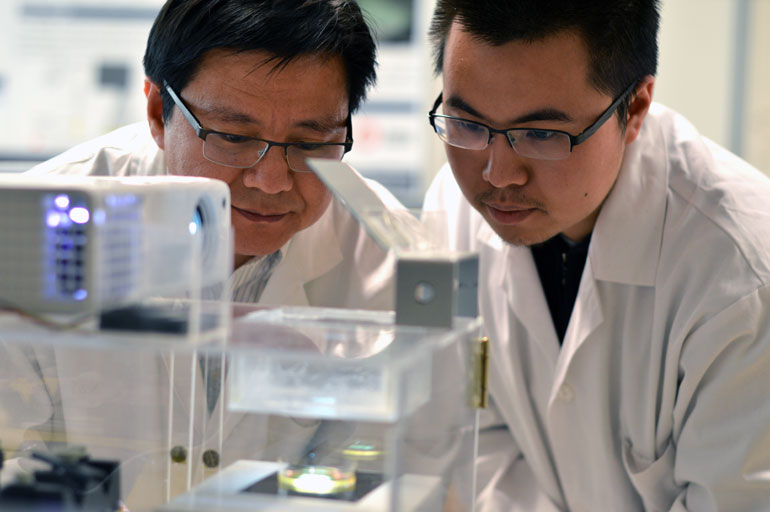

“UV light is known to be cancer-causing and can damage a cell’s DNA, which is not ideal when trying to create tissue for medical purposes,” said Keekyong Kim, the head researcher and assistant professor of Engineering at UBC. “By developing our own bio-ink, we can create bone, cartilage and tissue without the risk that we will make the cells sick in the development process.”

The 3D printing process works by combining processed cells with the newly developed bioink, which creates a hydrogel when exposed to light. Kim and his team used SLA printing in order to build the biomaterial in a layer by layer fashion, creating a scaffolding system to allow bone and tissue regeneration. For Kim, the biggest factor of the research was photo-initiating chemical compound that allowed the bioink to react to the much safer and affordable light projector, similar to the light source used for 3D printing with plastics.

“With our photo-initiator, we were able to use a more conventional light source, which hadn’t really been tried in 3D bio-printing before,” said Kim. “The result is we are able to make medical tissue in a way that is not only safer, it’s cheaper.”

Recently published in the Biofabrication journal, Kim and his collaborators, which includes Zongjie Wang, Raafa Abdulla, Benjamin Parker, Roya Samanipour and Sanjoy Ghosh, stand to push bioprinting towards actual implantation in the near future. Perhaps they will beat out Dr. Yoo’s 10-year projection, bringing bioprinted tissues and bones to the human body faster than we could have ever imagined.