The US Naval Postgraduate School (NPS) has announced a research collaboration with global print and digital document corporation Xerox to explore the potential for 3D printing to transform how the military supplies its deployed forces. As part of the agreement, NPS has installed the Xerox ElemX Liquid Metal 3D printer on its university campus.

ElemX is the name now given to the Xerox metal 3D printing platform displayed by Vader Systems at IMTS and acquired by Xerox in 2019.

Using the ElemX, NPS students and faculty staff will investigate how additive manufacturing can develop new capabilities for the US Navy and Marine Corps.

“The military supply chain is among the most complex in the world, and NPS understands first-hand the challenges manufacturers must address,” said Naresh Shanker, Xerox Chief Technology Officer. “This collaboration will aid NPS in pushing adoption of 3D printing throughout the US Navy, and will provide Xerox valuable information to help deliver supply chain flexibility and resiliency to future customers.”

Xerox’s step into 3D printing

With an established background in paper printing, Xerox entered the 3D printing sector initially as a reseller with intentions of “developing a roadmap to participate in 3D printing”. Xerox acquired liquid metal jet 3D printer manufacturer Vader Systems in February 2019, and later that year made its Formnext debut with a significant presence at the event.

At the show, Xerox showcased the development of polymer powders for SLS 3D printers and its Multi Nozzle Extrusion high-speed FDM system, in addition to its Liquid Metal 3D printing systems.

More recently, the firm ended its hostile takeover bid of competitor HP Inc citing concerns surrounding the ongoing Covid-19 situation. Xerox first made the $33.5 billion bid to acquire HP in November 2019 which was subsequently rejected and resulted in a proxy fight to replace the HP board at the start of 2020. While Xerox’s pursuit of HP has come to a halt for now, the firm maintains a deal between the two companies would be mutually beneficial in the long run.

Advancing 3D printing research

The Collaborative Research and Development Agreement (CRADA) between Xerox and NPS aims to explore new ways that Xerox’s technology can deliver on-demand 3D printing of metal parts and equipment for the US military. Through the partnership, NPS students will examine novel approaches to designing, creating, and prototyping with the ElemX 3D printer, alongside expanding manufacturing capabilities no matter the location.

“From the age of sail to the nuclear era, sailors have been fixing things at sea so they can complete the mission,” said NPS President, Ann Rondeau. “This partnership is about the strategic ability of the navy to have sailors on ships with the capability through creativity and technology to advance their operations at sea.

“Through collaboration, NPS and Xerox are helping build a navy for the 21st Century.”

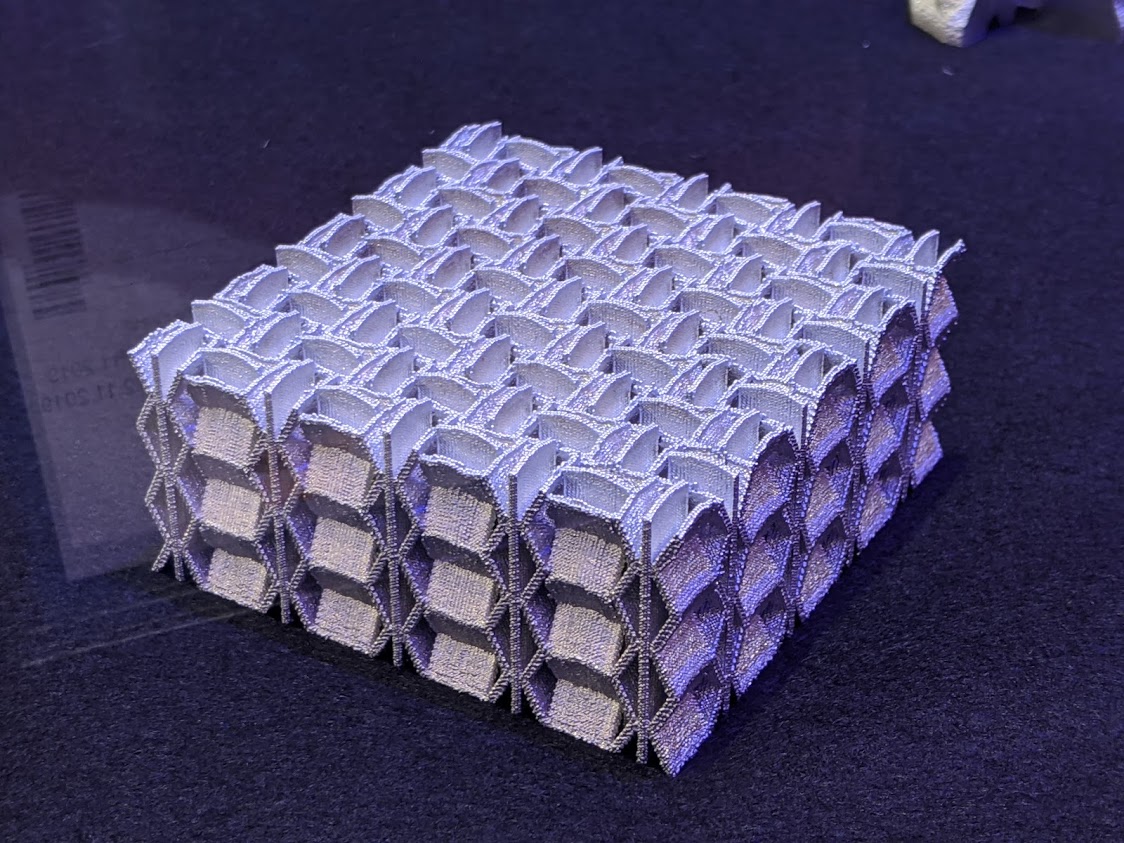

Xerox’s ElemX 3D printer uses aluminum wire to fabricate end-use parts to withstand operational demands and produce reliable replacement parts on-demand. According to retired US Marine Corps Colonel and Vice President of the NPS Alumni Association and Foundation, Todd Lyons, this technology can reduce dependency on the US military’s complex global supply chains while also providing cost benefits over traditional manufacturing.

“The NPS Alumni Association and Foundation supported bringing the ElemX liquid metal printer to NPS because it will enable soldiers, sailors, airmen, and marines to solve their problems where they are, when problems occur,” he said. “By providing the right digital tools and the liquid metal printer, all of a sudden we’ve helped to transform not just the supply chain, but how the Department of Defense thinks operationally about supplying war.”

The US military has previously dabbled with integrating 3D printing into its operations, having experimented with 3D printing missile parts, a digital twin project to re-engineer and 3D print parts for its Black Hawk helicopters and other vehicles, and customized earplugs for its soldiers. The army has also investigated a method for predicting 3D printed steel parts’ maintenance and performance, which could help it predict when parts will degrade or fail and need replacing.

In a press event last year, the head of Army Material Command Gus Perna stated the time had come for the US Army to develop a means for effectively deploying 3D printing within its arsenals, depots, and plants, having trialed the technology for some time.

The CRADA underway between Xerox and NPS will further the adoption of 3D printing across the US Military, and according to Xerox Vice President and General Manager Tali Rosman, this could be replicated across many other sectors, too.

“Global supply chains leave industries like aerospace, automotive, heavy equipment, and oil and gas vulnerable to external risks,” he said. “Our goal is to integrate localized 3D printing into their operations, and the real-time feedback from NPS gives us actionable data to continuously improve the ElemX.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the USS Harry S. Truman (CVN 75). Photo via the U.S. Navy/ Michael Chen.