Competition in the 3D printing industry is intensifying. At the industrial end of the market consolidation and takeovers are evident, while at the desktop 3D printing level enterprises are under pressure from an increase in the number of manufacturers.

California-based Type A Machines has become a casualty of this competition, and the well liked company has announced it will shut down.

3D Printing Industry has reported on Type A Machines since the company was founded in 2012, during that time approaches and attitudes to Open Source hardware have also shifted.

The full statement from Type A Machines reads as follows:

“It is with a heavy heart we announce that, after 6 years serving the maker community, Type A Machines is closing its doors.

As an industry pioneer, Type A Machines was birthed from the grassroots maker movement. Founded in 2012, its origins were at the NoiseBridge hackerspace and Tech Shop, moving to the East Bay to expand its manufacturing efforts.

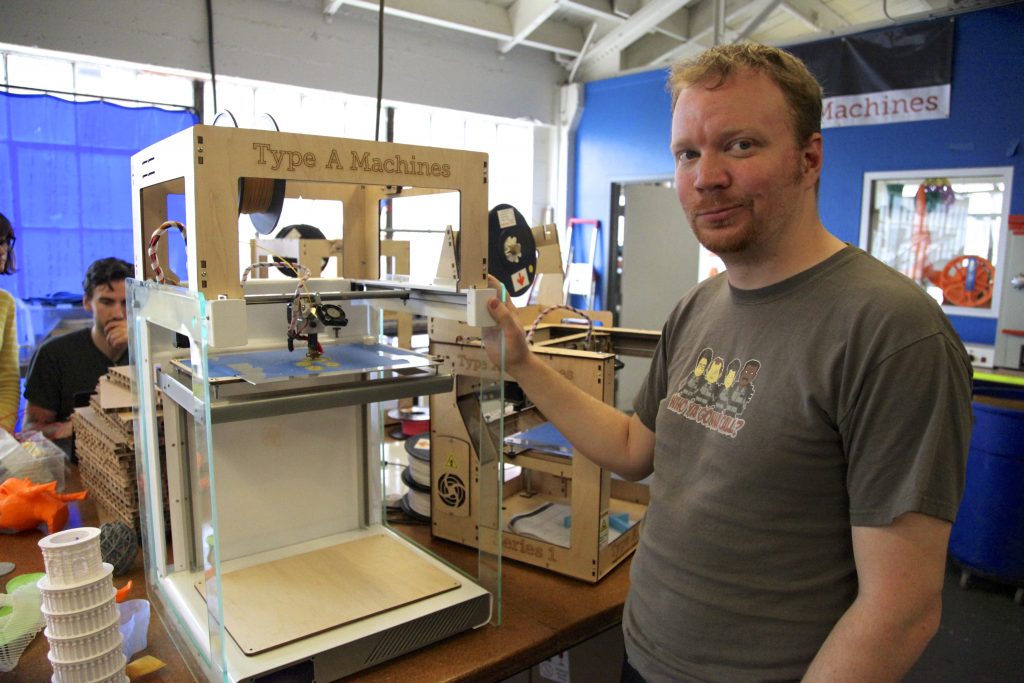

Makers of the award winning Series 1 3D printer, Type A Machines pushed the industry forward while remaining true to its open source origins. The Series 1 was the first 3D printer to include on-board Wi-Fi, the first to include material profiles, and thanks to its unique extruder, could print in more materials than any other 3D printer ever.

“I’m deeply appreciative and proud of the many customers, partners, and individuals who helped make Type A Machines a unique and innovative company, who pushed the boundaries of what was possible, and dedicated themselves to an ideal. Our future will be a bit better thanks to them.”

A future for modular 3D printing?

Re-reading interviews and articles about Type A machines might give a clues to why the business did not succeeded. In a 2013 interview former Type A Machines CEO Espen Sivertsen states, “We are trying to ensure that our 3D printers are future-proof — as much as any machine can be.”

One of the promises of 3D printing is the potential to reduce waste in comparison to subtractive manufacturing processes. In line with this ethos Type A Machines were very much focused on building future-proof, or modular machines. For users this would prove to be advantageous, permitting upgrades or repairs rather than replacing the entire 3D printer. However, this decision can also be viewed through a negative lens, as in the tech world obsolescence, whether planned or otherwise, is one way of ensuring repeat purchases from customers.

For context, it is worth considering the recent news that updates to Apple iPhones come with code that is alternatively described as a feature or a bug, depending on who you talk to. While the ethics of slowing down hardware through code updates are debatable, the tech world has become conditioned to expect a new product every year. However, this is not necessarily how the development of technology works.

Looking at another 3D printer manufacturer with a somewhat modular system reveals that the release schedule has slowed down. Award winning 3D printer manufacturer Ultimaker released the well received Ultimaker 3 in October 2016.

3D printing does still hold great promise for changing the product life cycle – from rapid design to spare parts that extend the life of consumer goods. While the news that Type A Machines has closed is of course sad, we are sure that the 3D printing industry has not heard the last from the founders and team behind the company.

Learn more about the latest additive manufacturing related technologies by subscribing to the most widely read newsletter in the industry, liking 3D Printing Industry on Facebook and following us on Twitter.

What software/hardware innovations are leading the 3D printing industry? Make your nominations for the 2018 3D Printing Industry Awards now.

Featured image shows Type A Machines Series 1 PRO 3D printer. Photo via Type A Machines.