When it comes to 3D printing, processes are often developed and defined using trial and error, because so many aspects of the technology not yet fully understood. This is particularly the case with 3D concrete 3D printing, which is becoming increasingly popular in construction.

Prof. Akke Suiker, professor of Applied Mechanics at the Eindhoven University of Technology (TU Eindhoven) has developed a series of formulae that define what happens during the 3D printing of concrete.

Using these, he has produced a mathematical model that engineers can use to determine the necessary parameters to 3D print stable walls, that neither buckle nor collapse fully during manufacture.

A build-up of concrete 3D printing

3D printed concrete structures have been appearing all over World. In 2016 the Institute for Advanced Architecture of Catalonia (IAAC) 3D printed a prefabricated concrete bridge over a river, and since then, firms such as AMT-SPETSAVIA have successfully 3D printed concrete houses.

In-situ concrete 3D printing, however, is more challenging. Two projects completed last year, 3D Printhuset’s Building On Demand and Yhnova’s Batiprint project took significantly longer than planned to finish.

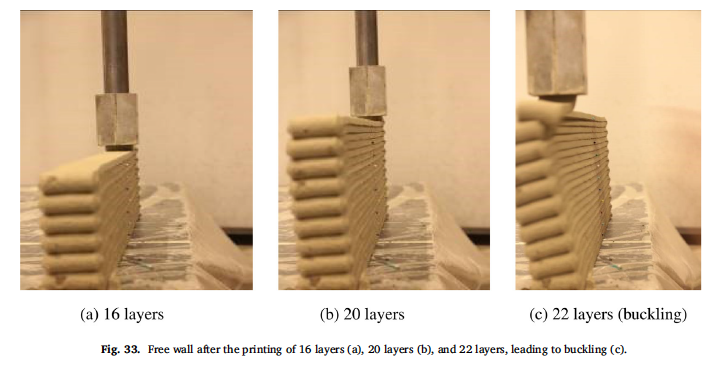

One common cause for complications lies in the speed at which concrete hardens. Unlike conventional concrete construction processes, concrete 3D printing does not allow lower layers to dry before another one is deposited over it. This can result in a wall buckling or collapsing, like poorly-thrown clay on a potter’s wheel.

Akke Suiker’s research

To address these complications, TU Eindhoven’s Prof. Akke Suiker has come up with a series of equations that address two types of failure in 3D printed concrete structures, namely elastic buckling and plastic collapse.

The failure types were analyzed for a free wall, a simply supported wall, and a fully clamped wall, the three most common configurations of 3D printed concrete structures.

As part of his working, Suiker derived a buckling model of a wall structure from an equilibrium equation and a mathematically defined boundary conditions of the 3D printed concrete. The speed of 3D printing the concrete and the process of the concrete drying were then factored in to determine the conditions under which a 3D printed concrete wall will fail.

Finally, Suiker factored in potential imperfections in the 3D printed wall and their influence on buckling and collapse, completing the model.

Application of Suiker’s equations

Using the equations that make up the model, Suiker was able to calculate how quickly layers can be 3D printed, given the material curing characteristics and wall dimensions, without the structure collapsing.

Additionally, the model shows how to make the structure with as little material as possible, the influence of structural irregularities the effect of making wall slightly thicker, and the impact of increasing the material curing rate.

Asked about the impact of his equations on 3D printing, Suiker said:

“The insights provided by the model create essential basic knowledge for everyone who prints 3D structures. For structural designers, engineering firms but also, for example, for companies that print thin-walled plastic prostheses of small dimensions, because that is where my equations also apply.”

Thus, the models can be applied to FFF 3D printing with completely different materials, with an insight into whether a buckling or plastic collapse failure is localized or will also affect the rest of the connecting structure.

Validating Suiker’s model

TU Eindhoven has itself undertaken 3D printed concrete projects on its own giant concrete 3D printer, including a 3D printed concrete bicycle bridge made in conjunction with the Royal BAM Group.

To validate the equations, Suiker first used the concrete 3D printer to manufacture a free wall, followed by a rectangular wall layout. In each case, the buckling lengths of the 3D printed concrete wall were in agreement with lengths predicted by the equations and analysis using Finite Element Method (FEM).

A second validation was completed using a computer model developed by TU Eindhoven Ph.D. candidate Rob Wolfs. This model relied more on FEM analysis of specific 3D printing conditions but supported Suiker’s findings.

Suiker will next be presenting his research in an engineering seminar at the University of Cambridge in March.

The full paper, “Mechanical performance of wall structures in 3D printing processes: theory, design tools and experiments,” by Akke Suiker is available to read online via the International Journal of Mechanical Sciences.

Let us know who you think the most important educator of 3D printing has been this year. Make your nominations for the 3D Printing Industry Awards 2018 now.

For more stories on structural 3D printing subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows TU Eindhoven’s robot controlled concrete 3D Printer. Photo via TU Eindoven.