Researchers at Eindhoven University of Technology (Tu/e) in the Netherlands have released a proof-of-concept article on 3D printed, self-expanding, biodegradable stents. The stents are designed to be minimally invasive, supporting narrow or weak arteries of the heart particularly in cases involving children.

Combatting heart disease

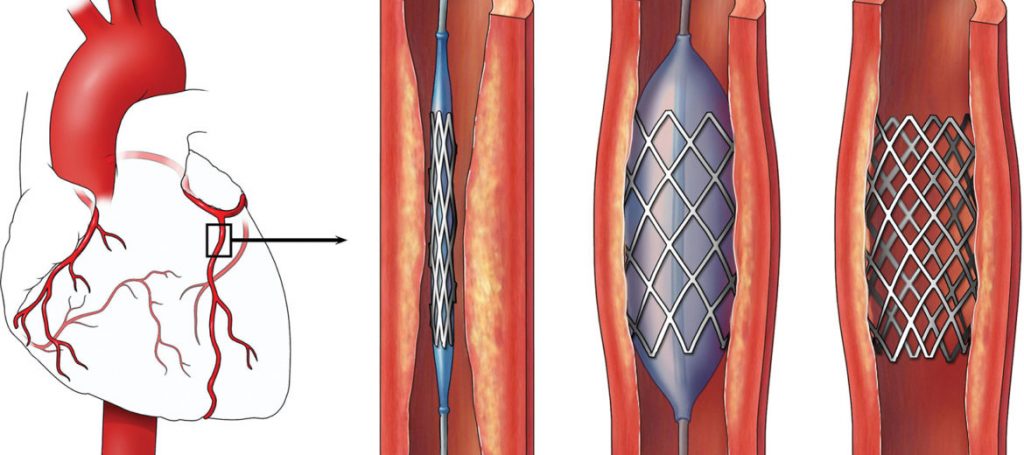

As shown in the diagram above, stents are used to open up arteries that have become thick or weakened through the build up of plaque caused by heart disease. In a typical installation of a stent, a balloon is used to expand the mesh material, and push apart the plaque build-up in the artery. Over time this stent is absorbed by cells to become part of the artery – a process essential to its success, as removal would cause further damage to the artery.

In place of this balloon system, the Eindhoven team proposed a stent that expands autonomously inside the artery. Eindhoven’s stents are also made from an absorbable polymer instead of typical nickel titanium (nitinol) metal, to promote comfort and acceptance in the body.

Putting plastic stents to the test

Using the design parameters of a typical nitinol stent, researchers create a computerized design of a plastic polymer stent. Through simulated crush tests, the design of the plastic stent is modified by degrees until it matches, or exceeds, the required response as achieved in nitinol.

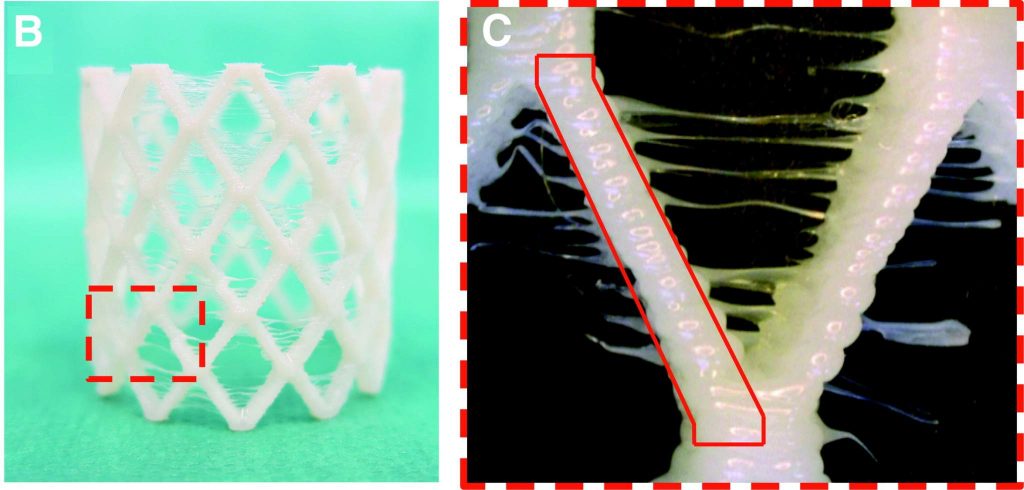

Experimental stents are then FDM 3D printed on a MakerBot Replicator 2X. The material used in the prototypes is FlexiFil, a TPC (Thermoplastic Co-Polyester) filament with flexible qualities comparable to rubber. FelixFil is made by Formfutura.

Prototypes undergo multiple tests to asses mechanical and biodegradable abilities. These results are also compared to the same tests for nitinol stents, ensuring an appropriate match.

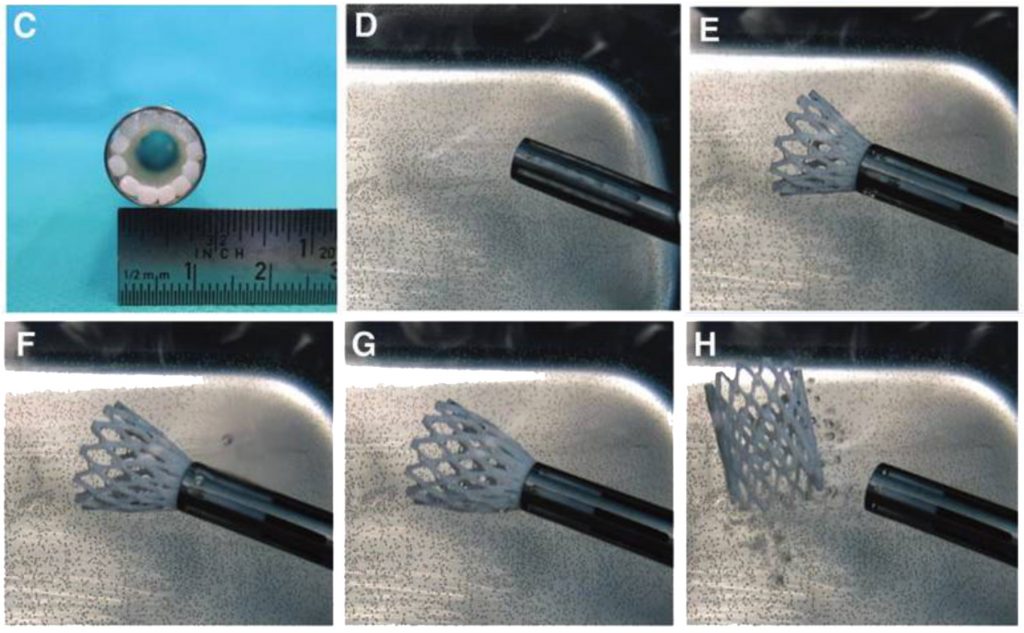

In crimping tests, FlexiFil stents are shown to be capable of fitting within the desired diameter of 10mm. Added to water, the stent displays its expanding capabilities by pushing its way out of a rigid tube.

To ensure the stents would biodegrade within the body, researchers conducted an accelerated hydrolysis test, keeping samples in a temperature-controlled water bath of 90°C. After two weeks of in vitro hydrolysis, the stents demonstrated enhanced porosity, which is encouraging to cell adoption.

Supramolecular materials and future in vivo testing

In the discussion, researchers propose further study into biocompatible, supramolecular, i.e. multimaterial, polymers that also match the requirements of 3D printing. They also hope to test flexible TPC in vivo in an animal model, and engineer the material to degrade only after 16 weeks in a bio-environment.

Other research into the improvement of heart stents has been undertaken at Northwestern University, Illinois, where researchers used a process termed “micro continuous liquid interface production” to make the devices. A collaboration between Toulouse University Hospital’s Pulmonology department and local start-up AnatomikModeling have also used 3D printing to make, and implant, a custom stent for a patient’s airways.

Computationally Designed 3D Printed Self-Expandable Polymer Stents with Biodegradation Capacity for Minimally Invasive Heart Valve Implantation: A Proof-of-Concept Study is published online in 3D Printing and Additive Manufacturing journal, Volume 4, Number 1, 2017. It is co-authored by María Sol Cabrera, Bart Sanders, Olga J.G.M. Goor, Anita Driessen-Mol, Cees W.J Oomens, and Frank P.T. Baaijens.

For more of the latest research applications of 3D printing, sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Freatured image: The 3D printed TU Eindhoven stents before (left) an after (right) experimentation. Photo via Mary Ann Liebert, Inc