German machine tool manufacturer TRUMPF has announced the takeover of its joint additive manufacturing venture with Italian 3D printer developer SISMA.

Expected to go through by the end of 2021, the deal will see TRUMPF take full control of ‘TRUMPF SISMA S.R.L,’ the Laser Metal Fusion (LMF) 3D printing business it founded alongside SISMA. As part of the agreement, TRUMPF is set to begin marketing LMF machines to users in the industrial, dental and medical sectors, while SISMA will now distribute them to clients operating in its core jewelry and fashion markets.

Ending a seven-year partnership

Based in the Northern Italian town of Schio, TRUMPF SISMA was founded in 2014 with the aim of developing a production system capable of 3D printing metal parts with industrial applications. At the time, SISMA was said to have been working on such a machine for several years, and the joint venture offered TRUMPF the chance to re-enter a sector it had initially broken into in 2000 with the TrumaForm.

Fast forward to 2021, and TRUMPF has gone on to establish a strong metal 3D printing portfolio with its TruPrint systems, while SISMA has begun to market LMF-driven machines of its own. Given that any parts produced via these 3D printers are melted rather than sintered, they tend to feature an extremely rough surface but also have very high (close to 100%) densities, lending them enhanced strength.

To enable such parts to be rapidly post-processed for end-use, SISMA has therefore integrated the technology into its MYSINT machines. Each of these features a unique tilted coating system that rapidly rotates parts upwards before returning them to their powder collection position, in a simple set up, that drives productivity and makes the 3D printers appealing to industrial manufacturers.

Following its takeover of TRUMPF SISMA, a venture in which it previously held a 55% stake, TRUMPF now stands to inherit SISMA’s LMF 3D printing business. However, once the deal has gone through, TRUMPF intends to trade the business as before, continuing to address SISMA’s industrial and medical clientele, leveraging its sixty-staff-strong Italian facility.

For its part, SISMA has revealed that it plans to refocus on the jewelry and fashion markets moving forwards, where it will now work with TRUMPF to distribute LMF machines. Having announced the sale of its 45% share in TRUMPF SISMA, the company stated that it “thanks TRUMPF for its collaboration that has lasted so far,” and it “looks forward to a productive commercial partnership” in future.

Re-entering the entry-level space?

With a projected turnover of €3.9 billion for the 2021/22 financial year, TRUMPF is one of the world’s largest machine tool and laser producers for industrial manufacturers. Although the firm’s offering is not restricted to 3D printing, as it markets everything from laser cutters to bending, punching and welding systems, it has built up a strong metal printing portfolio.

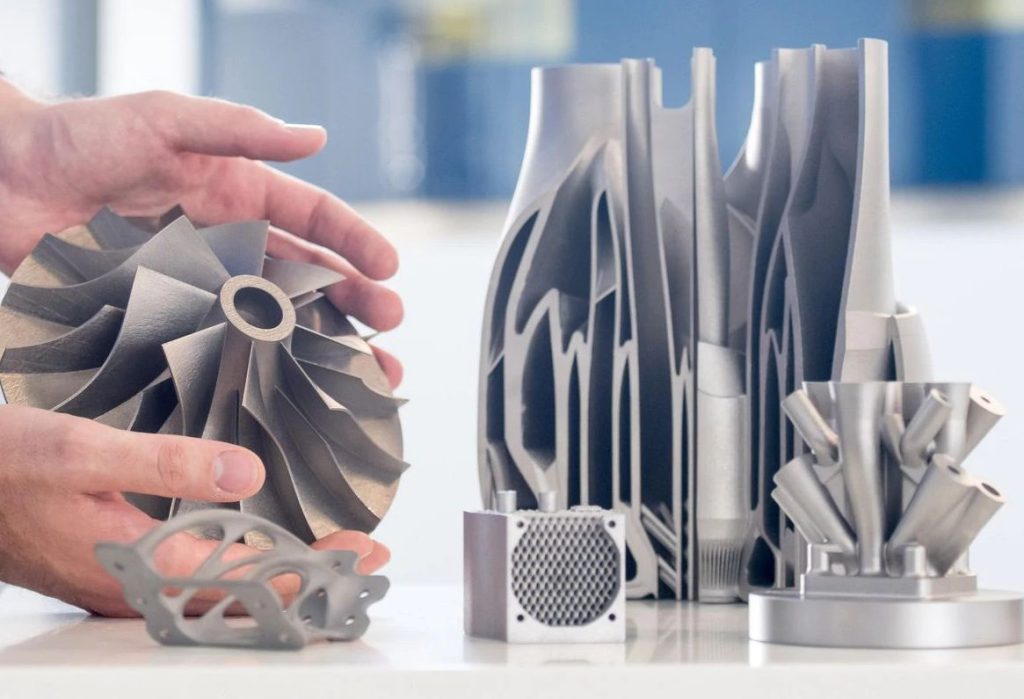

At present, TRUMPF’s additive manufacturing lineup comprises its own LMF-driven TruPrint 1000, 2000, 3000 and 5000 machines, as well as its Laser Metal Deposition (LMD)-powered TruLaser Cell 3000, 7040 and DepositionLine technology package.

While the former are designed to enable metal part manufacturers to enter serial production, and offer cylindrical build volumes from 100mm x 100mm up to 300 mm x 400 mm, the latter can be used for 3D cutting and welding in addition to LMD, making it an attractive option for those seeking to produce complex, medium-sized components in an automated way.

In the past, the company’s technologies have often been used within the aerospace and automotive sectors, with the likes of Porsche LMF 3D printing upgraded pistons for its 911 sports car in July 2020. TRUMPF has also worked with Heraeus AMLOY to improve the cost efficiency of additive manufacturing ultra-lightweight amorphous metal parts, as part of its drive to better infiltrate industrial environments.

Elsewhere, TRUMPF has toyed with the idea of offering entry-level metal 3D printers via its One Click Metal subsidiary, but it opted to sell the business to the INDEX Group earlier this year. Now, with its acquisition of TRUMPF SISMA and its MYSINT machines, the company appears to have bought back into the low-cost segment, although it remains to be seen if it will attempt to scale LMF moving forwards.

Making metal AM more accessible

With the likes of SLM Solutions, Farsoon and EOS continuing to launch ever-larger industrial-scale 3D printers, it can be difficult for those seeking to conduct metal additive R&D to find an affordable means of doing so. Luckily for them, the likes of Xact Metal aim to address this very application, and the company recently unveiled two new sub-$90,000 metal 3D printers ahead of the Formnext 2021 trade show.

Meltio also offers an affordable metal manufacturing alternative, in the shape of its modular Meltio Engine, a 3D printing cell that can be integrated with CNC machines and robotic arms to enable hybrid production. The firm unveiled an upgraded LMD module in December 2020, which is said to be capable of fabricating fully-dense parts from various metals such as steel, Inconel, titanium and more.

On the Electron Beam Melting (EBM) front, meanwhile, Freemelt has set out to develop a lower-cost, open-source approach to material development with its Freemelt ONE 3D printer. Reportedly requiring less powder during alloy qualification than other similar systems, the firm hopes that its machine can help accelerate the rate at which EBM printable alloys can be identified and deployed.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows TRUMPF’s headquarters in Hüttinger, Germany. Photo via TRUMPF.