3D printing service bureau Tronix3D has announced that it has completed a successful technology demonstration as part of the National Center for Defense Manufacturing and Machining’s (NCDMM) AMNOW Program.

The event took place last month, and officials from the U.S. Army Combat Capabilities Development Command (CCDC) and program partner LECS Energy LLC were in attendance. The program ultimately aims to support the adoption of 3D printing in the existing U.S. Army supply chain via the development and validation of a prototype digital AM supply chain. Tronix3D’s demonstration, specifically, involved showcasing the implementation of LECS Energy’s Learning Integrated Manufacturing System (LIMS), a new process data collection technology.

Ashley Totin, Senior Project Engineer at NCDMM, states: “As the lead of the AMNOW program, we are pleased with Tronix3D’s progress, as well as the outcome of the demonstration, and are excited about continuing our relationship. This visit was significant for us to identify the future benefits of the data being collected by Tronix3D, including perpetual updates to cybersecurity protocols, process optimization, and overall operational efficiency.”

Real-time data collection with LIMS

The demonstrated LIMS technology serves to form a secure digital connection through a supply chain via high-level cryptographic hardware – the likes of which are not usually deployed in run-of-the-mill manufacturing environments. NCDMM has also stated that it is a critical edge device within the cloud-based Advanced Manufacturing Intelligence Platform (AMIP). AMIP is employed by the U.S. Army to transfer manufacturing process information to and from its suppliers in a rapid manner, and has been used to build confidence in 3D printed critical parts since its launch.

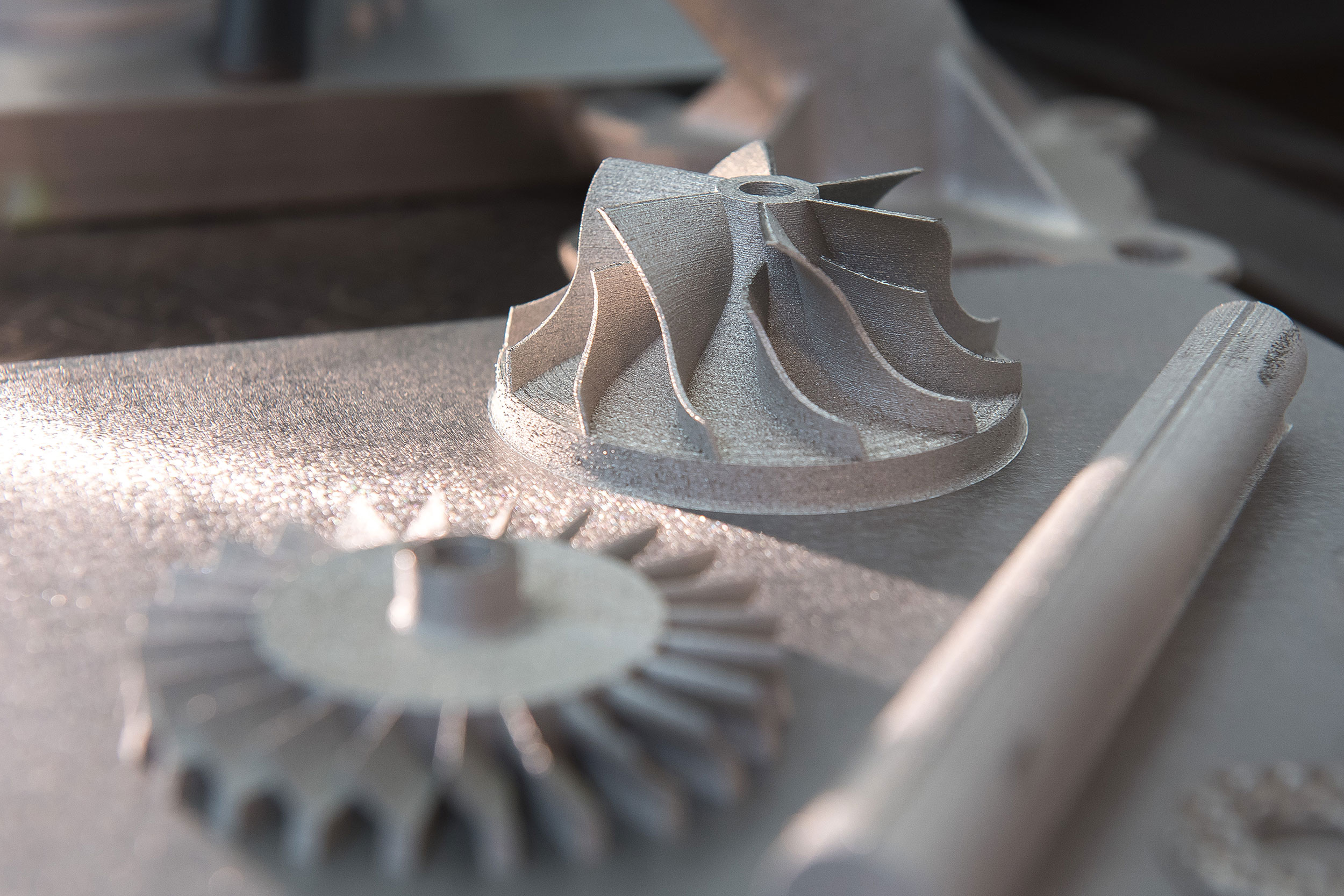

Over the course of its demonstration, Tronix3D showed the power of LIMS’ real-time data collection capabilities on a Trumpf industrial 3D printer via operations software, IoT sensors, and even embedded programmable nanoparticles. To aid with the showcase, industrial partner Trumpf also allowed access to the real-time machine data its metal 3D printers are inherently capable of collecting.

Buck Helfferich, President of Tronix3D, adds: “One of the goals Tronix3D has within the project is to improve data collection and transference during additive manufacturing to help maintain and control the 3D printing process. This monitoring is an important component of the manufacturing process to ensure a repeatable production process of high-quality parts.”

Additive manufacturing programs with the Armed Forces

Funded by the CCDC, AMNOW is a multi-year contract program with multiple phases and a whole host of program partners. However, this certainly isn’t the first instance of the U.S. Armed Forces organizing and funding additive manufacturing-related programs for the benefit of the country’s defense capabilities.

Just last month, the U.S. Air Force Rapid Sustainment Office announced the conclusion of its first Advanced Manufacturing Olympics, with five technical design challenge winners and a total of nearly $1M in prizes. The virtual event, which took place from October 20 – 23, brought together a plethora of industry experts, academics, and government officials to witness the potential of 3D printing in the defense sector.

Elsewhere, 3D printing innovation institute America Makes recently awarded $2.3M in funding across three project calls aimed at accelerating the adoption of additive manufacturing in defense and other sectors. Partly funded by the Air Force Research Laboratory, the Open Project Call was divided into three focused technical areas.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Tronix3D demonstrating the data collection capabilities of the LIMS technology. Photo via NCDMM.