Industrial 3D printer OEM Triditive has announced the completion of a $1.8M seed funding round.

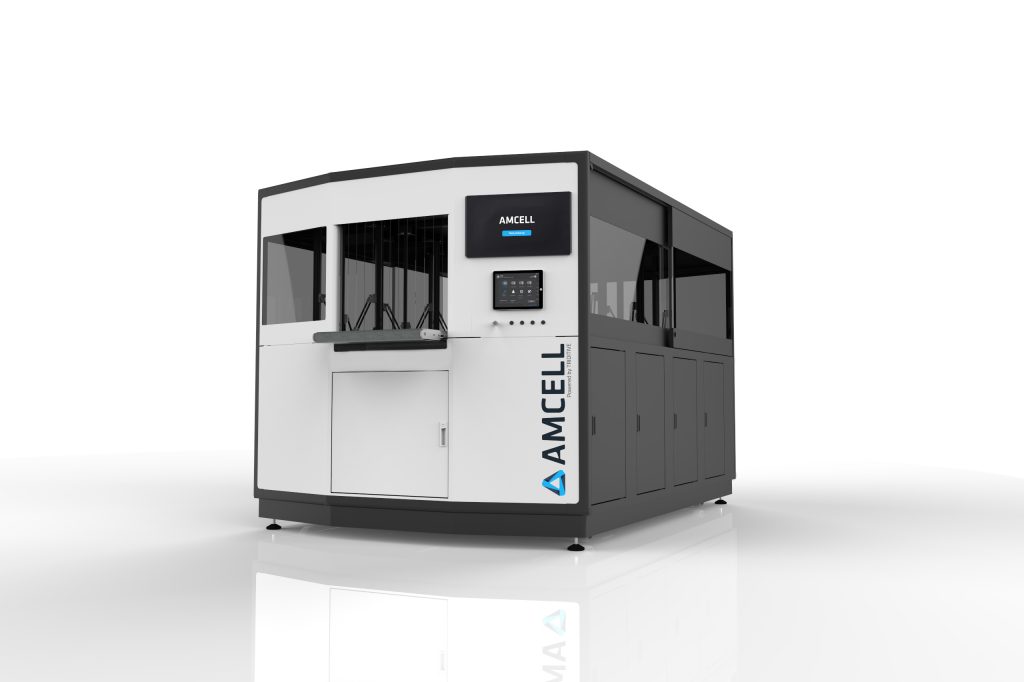

The company will use its capital injection to further develop its proprietary AMCELL system, a large-format modular 3D printing cell designed for high-throughput automated production. The machine utilizes both advanced robotics and machine learning-based software algorithms to facilitate the series 3D printing of metal and polymer parts on the shop floor.

Supported by new investors and existing shareholders alike, the seed round included industry leaders such as Stanley Ventures (Stanley Black & Decker), Techstars, Hunosa Empresas, Fourth Funding, IDEPA, and a number of business angels from Spain, France and Switzerland.

Mariel Diaz, CEO of Triditive, states, “We are delighted to welcome our new investors and thankful to our existing shareholders for their continued support. This funding validates our approach to industrialize additive manufacturing through automation and enables us to expand our market presence.”

Automated series production with the AMCELL

Dubbed a ‘Factory in a Cell’, the AMCELL is composed of eight individual robotic modules. With a build volume of 220mm diameter x 330mm each, they work independently but simultaneously for 24/7 end use component production. The system is based on the company’s own AMD (Automated Multimaterial Deposition) technology, which comprises both a binder jetting module and several delta FDM modules for compatibility with metals, polymers and fiber-reinforced composites.

The cell is integrated with automation subsystems that handle the loading and ejection of the various manufacturing platforms, as well as the auto-calibration for each 3D printing module. Once a part is complete, it is ejected onto a central conveyor belt where it is ready to be collected.

The production chamber is also fitted with temperature control, humidity control, and air filtering systems. As such, the machine is capable of maintaining the optimal 3D printing conditions for the parts being produced. The cartridge loading system also controls the environmental properties of the materials while they are in storage, with a capacity of up to 10kg of raw material per module.

Having recently opened a 20,000 square foot factory in Asturias, Spain, the company intends to operate the largest 3D printing facility in the country when it comes to production capacity. The factory will be lined with AMCELL systems connected via the company’s cloud-based EVAM software, which enables part tracking, traceability, manufacturing order optimization, and even quality control.

Sean Wright, Managing Director at Stanley Ventures, said, “We see tremendous growth potential in the Additive Manufacturing industry. Triditive demonstrated its ability to innovate and create a novel product. We look forward to working with the team to extend our impact in the Additive Manufacturing industry.”

Seven figure funding in the 3D printing industry

Despite only being a month in, 2021 has already yielded a number of multi-million dollar funding stories in additive manufacturing. The University of Maine recently secured $2.8M in funding from the U.S. Department of Energy to develop a more eco-friendly method of 3D printing wind turbine blade molds. The team will introduce a bio-based feedstock into their Cellulose Nanofiber (CNF) printing process in a bid to cut the costs of producing the large-format parts by 50%.

Elsewhere, geometric deep learning firm Physna recently raised $20M in Series B funding which it will use to grow its team and further develop its 3D printing software offering. The funding round brings the company’s total capital raised to $29M.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Triditive’s 3D printing factory in Spain. Image via Triditive.