3D Printing Industry is taking an in depth look at how additive manufacturing is moving to production. Over the coming weeks the results of interviews with industry leading practitioners will be published.

This article is part of a series examining Trends in Additive Manufacturing for End-Use Production.

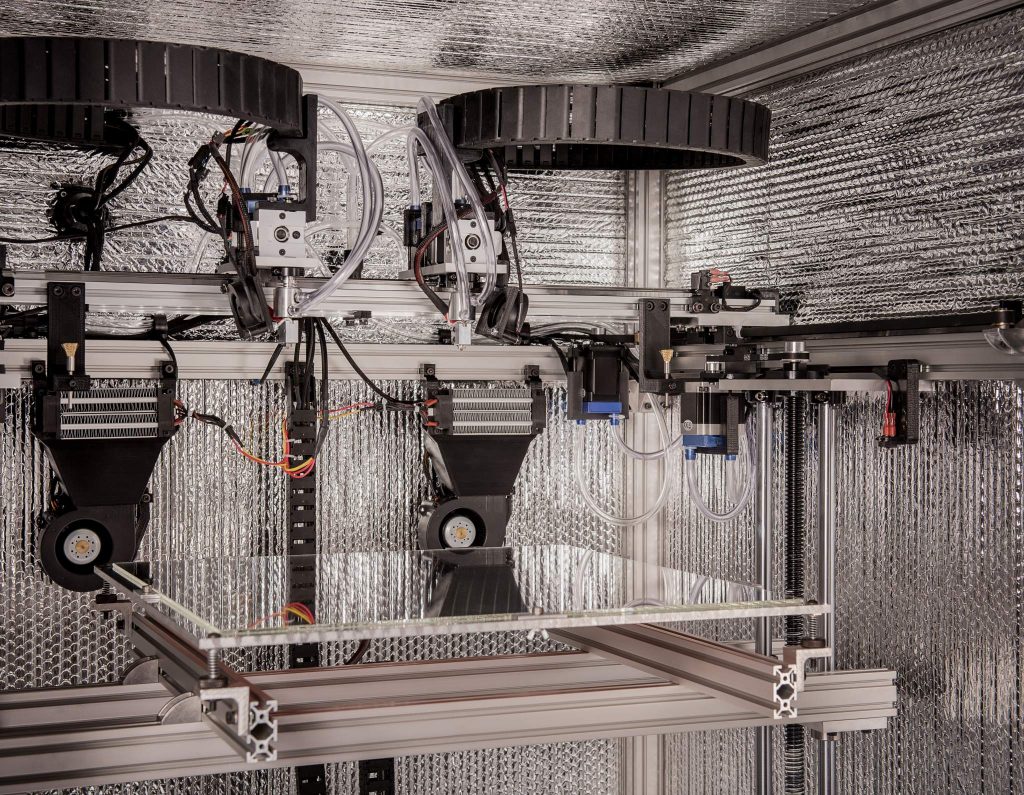

Randeep Singh is co-founder of AON3D. Based in Montreal, Canada the company’s AON-M industrial 3D printer uses high-end production grade thermoplastics such as PEEK™ and ULTEM™.

3DPI: What is your percentage estimate of how much your printers are used for production versus other applications?

Randeep Singh: Based on what we’re seeing, we estimate about 15% of our customers are using AM for end-use parts. If you include manufacturing tooling/jigging/fixtures that number rises dramatically (25%+). A lot of customers are currently evaluating AM internally, with the hope to move it to end-use in the future.

3DPI: Which industries/verticals are leading in the use of AM for production?

RS: Robotics is a huge one – many custom robotics systems don’t ever hit the production volumes for mass manufacturing techniques. Drones & aircraft are another one, where AM’s ability to work with complex geometries allows for significant weight savings — though qualification of parts is an issue.

Manufacturing is probably the biggest adopter, because AM produced tools/jigs/fixtures have such an immediate payback period (when compared to current solutions), that it’s almost a no-brainer.

3DPI: What barriers does AM face for production and how are these surmountable?

3DPI: What barriers does AM face for production and how are these surmountable?

RS: Part Strength – parts printed with low-quality materials aren’t fit for end use because they don’t have the requisite performance ability for a lot of use cases. The trend of higher-strength plastics becoming useful is changing users perspective of what’s possible with AM.

Reliability – for a lot of businesses, AM is a cost & lead-time play — meaning that it’s being used to either significantly speed up a manufacturing process or development process, or used to cut costs (via no requirement for initial tooling/outsourcing). If printers operate unreliably, than it wastes valuable human time, which greatly affects the overall ROI.

Cost – Traditional industrial AM systems are producing parts at close to or above to costs of outsourcing/other techniques. This was making AM a hard sell internally, but with the new generation of products that have a more useful cost-per-part, we’re seeing a lot more interest especially from smaller manufacturers/firms.

Certification matters more for aerospace, but there’s tons of non-aerospace applications that exist, so I think we’ll still see a lot of adoption

It’s not just the hardware – it’s the materials & process engineering too. Every material, and every part is different, and the result is that each combination (of the two) probably has different optimal process settings. This is something we’re working hard on because it’s the primary cause of print failure.

Process settings/variables matter a lot more in high-strength polymers than in low-strength ones, and can produce part strength variation as high as 2-300%.

Awareness.

3DPI: Are there any notable trends in AM for end use production?

RS: The fact that high-end materials are possible to work with is huge – it’s the primary driver opening up end-use markets. We’re seeing a trend of people obtaining an AM solution, and realizing how much more powerful it can be once they learn how to use it. As the AM solutions become more and more user friendly, we predict this trend to continue.

This article is part of a series examining Trends in Additive Manufacturing for End-Use Production.

You can read more about AON3D here and also on the company’s website.

If you found this insight useful, then subscribe to our newsletter and follow us on social media.

Featured image shows the AON3D team and AON-M 3D printer at RAPID 2017. Photo by Michael Petch.