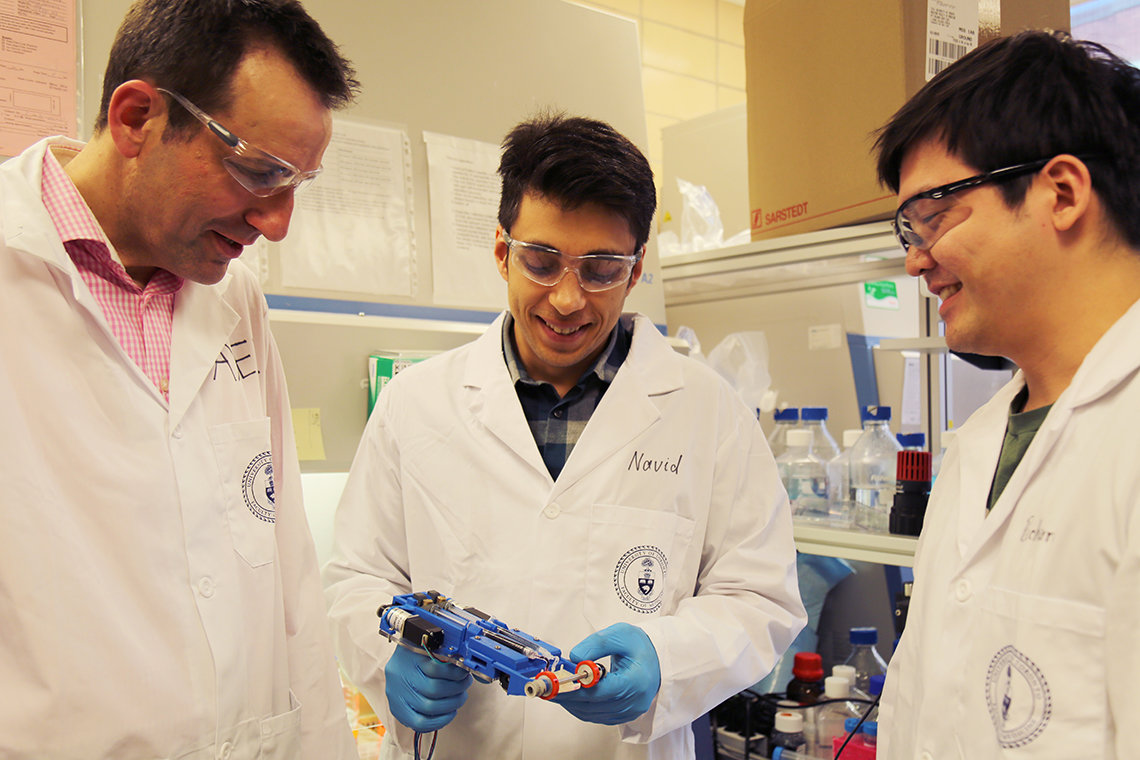

Scientists from the University of Toronto (UoT) and Sunnybrook Research Institute (SRI), have created a handheld 3D bioprinter capable of printing skin cells to treat deep-thickness wound on burn victims.

According to the research recently published in the Lab on a Chip journal, “When manually positioned above a target surface, the compact instrument [weighing 0.8 kg] conformally deposits a biomaterial or tissue sheet from a microfluidic cartridge.”

The ‘first’ handheld bioprinter

According to the World Health Organization (WHO), an estimated 180,000 deaths annually are caused by burns – the vast majority occur in low-and-middle-income countries. Seeking methods to treat burn victims remotely, Navid Hakimi Ph.D. student at UoT, and Dr. Marc G. Jeschke, a Professor of Immunology at UoT and Director of the Ross Tilley Burn Centre at Sunnybrook Hospital led the research of the portable 3D bioprinter.

“Most current 3D bioprinters are bulky, work at low speeds, are expensive and are incompatible with clinical application,” said Dr. Axel Guenther, Associate Professor at UoT’s Faculty of Applied Science & Engineering, who supervised the research project.

Bioprinting versus skin grafting

Skin grafting, the surgical transplantation of skin tissue, requires a significant amount of healthy donor skin to travel across the three layers of the skin on deep wounds – the epidermis, dermis, and hypodermis. Nevertheless, according to the research, large amounts of healthy donor skin is not always available.

With minimal operating training, the handheld bioprinter deposits epidermal and dermal cells as well as a mixture of bio-neutral polymers and proteins for even distribution of the cells layers. This process has the potential to replace skin grafting processes as the “skin” printed can be layered in multiple sessions to heal a deep-thickness wound.

The scientists have also incorporated hyaluronate, a protein found in human connective tissue into the printer model. This protein has the ability to promote healing and integrity among cells and collagen. A test was conducted on agarose (a linear polymer) substrates in in vitro conditions. This process validated the bioink’s ability to be extruded inconsistent narrow sheets with the desired content, width, and thickness.

Following these tests, the team conducted in vivo studies, which applied the entire 3D printer to deep skin wounds in experimental pig and mouse skin. The bioink stripes were able to cover the wounds in their entirety, using various angles. The technology is now being developed for human testing.

3D printing and wound care

Additive manufacturing has contributed to innovative solutions for medical skin treatments and wound care. Last year, scientists from the VTT Technical Centre of Finland, a state-owned research and development non-profit, have developed a nanostructured cellulose 3D printable smart-dressing and 3D printed circuit board that heals and monitors skin wounds.

Prior to this, a research team at Pohang University of Science and Technology (POSTECH) in Korea, developed a skin 3D bioprinting process which uses extrusion-based and inkjet printing depositing advanced bioink materials. This method accelerated the growth of tissues in the layers of human skin, demonstrating a substantial skin culture in 2 weeks.

The research paper, “Handheld skin printer: in situ formation of planar biomaterials and tissues” was co-authored by Navid Hakimi, Richard Cheng, Lian Leng, Mohammad Sotoudehfar, Phoenix Qing Ba, Nazihah Bakhtyar, Saeid Amini-Nik, Dr. Marc G. Jeschke, and Axel Guenther.

Stay updated with the latest scientific developments in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the handheld 3D bioprinter depositing skin cells onto a substrate.Clip via UoT.