Titomic, the Australia-based firm behind the Titomic Kinetic Fusion (TKF) 3D printing process, has acquired rival Netherlands-based cold spray technology company Dycomet Europe.

The transaction ultimately serves to bolster Titomic’s presence on the global stage as the firm now has a new base in Europe, along with its original Australian headquarters and the Titomic USA subsidiary. The deal will also provide an immediate source of revenue for Titomic, seeing as Dycomet Europe brings with it a healthy pipeline of customer orders across the continent.

Herbert Koeck, Chief Executive of Titomic, said, “The acquisition of Dycomet is a significant step in Titomic’s strategic pathway to being a global company. We are excited to welcome Dycomet onboard and look forward to working with the team on the many exciting opportunities that this acquisition presents.”

Titomic and Dycomet: experts in cold spray 3D printing

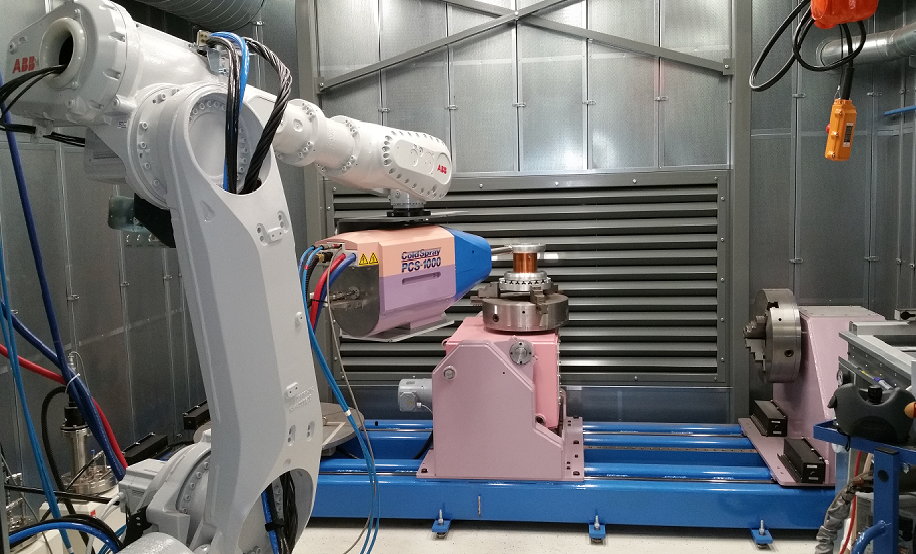

Titomic and Dycomet are both developers of metal cold spray 3D printing technologies. The cold spray process involves spraying a metal powder onto a substrate, much like you’d spray paint onto a graffiti wall. As the name might suggest, the technique doesn’t rely on lasers or any other heat-based energy sources and leverages kinetic energy instead. Metal powder is jetted out using a high-velocity compressed gas stream, which gives the material enough energy to deform and bond to the solid part below, forming additional layers.

Titomic’s proprietary TKF technology is a form of high-pressure cold spray, qualifying it for high-performance applications in industries such as aerospace and defense. Earlier this year, the company received a Purchase Order for a Statement of Work with international aerospace giant Airbus. The purchase order concerned near-net demonstrator parts for a targeted aerospace application 3D printed using the TKF process.

More recently, Titomic also signed a partnership with machine tool manufacturer Repkon to jointly build a new defense-focused 3D printing production facility in Australia. The factory will be used to fabricate Repkon-designed weapons system barrels using the company’s additive technology.

Dycomet, on the other hand, has been developing low and medium-pressure cold spray systems solutions since 2006. The company also offers research and development services via its in-house laboratory, software development services, and various spare parts and consumables for its manufacturing systems. Dycomet’s client list already includes several big-name brands such as Rolls-Royce, Mercedes, Airbus, Siemens, and Volkswagen.

Koeck adds, “While Titomic focuses on high-pressure applications, Dycomet services the soft-end low and medium-pressure market. With our complementary machinery and product portfolio, the combined expertise now available to the Company will further accelerate the Company’s growth into new markets and provide current customers with a broader product offering.”

Klaas Rozema to lead Titomic Europe

Following the acquisition, Klaas Rozema, Dycomet’s current Founder and CEO, will lead the newly-established Titomic Europe subsidiary as its General Manager. Having spent 13 years crafting Dycomet into the business it is today, Klaas brings with him a deep understanding of the cold spray market.

Rozema said, “I am delighted that Dycomet has been acquired by a new owner who understands our industry. Titomic is an excellent complementary fit with our current product set and expertise and can support the next phase of growth, offering a wealth of opportunities for our team.”

Titomic and Dycomet have already set out plans to roll out several business operations together, including adding to Titomic’s product portfolio, using complementary machinery sets from both sides, servicing and maintaining additional machinery in Europe, and providing technical and sales services in the region.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Dycomet’s own low-pressure cold spray 3D printing hardware. Photo via Dycomet.