Insiders and analysts predict the 3D printing trends to watch in our latest series of articles focused on the future of 3D printing.

Riskable, a hobbyist toymaker, and 3D printing enthusiast has developed an innovative new key switch mechanism for use in PC keyboards.

Named ‘Void Switch’, the design is completely open-source and can be fabricated at home with any run-of-the-mill FFF 3D printer. The novelty of the mechanism lies in its use of magnets, which makes it levitation-based and entirely contactless. In contrast, standard mechanical keyboard switches rely on springs and metallic contact plates to determine whether or not a key has been pressed.

Interestingly, the Void Switch mechanism is also fully customizable in its feel, allowing users to adjust both the tactility and return force of the keys based on personal preferences.

The world of mechanical keyboards

While the average person probably doesn’t give their computing peripherals much thought, those in the PC gaming and programming communities tend to have a special affinity for kitted-out mechanical keyboards.

Unlike the compact keys found on a laptop, mechanical keys feature more depth and provide a much more satisfying feel when pressed down. You can usually tell the difference between the two from the sounds they make: mechanical keyboards often deliver a louder ‘clack’ sound.

Beyond just the RGB lighting, mechanical keyboards can be modified and customized in almost every aspect from the casing and stabilizers to the keycaps and key switches. The key switches, in particular, are what determine the tactile response of the keyboard, whether it’s a click, bump, or smooth descent all the way down.

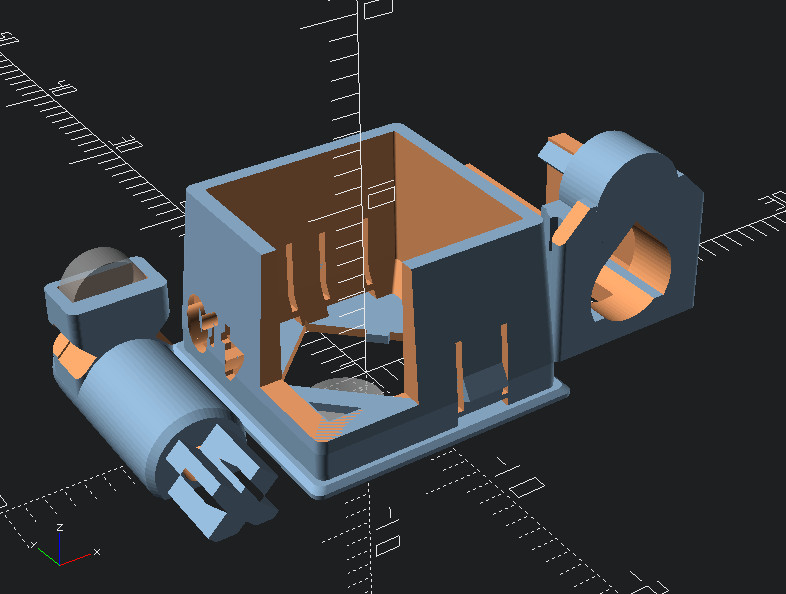

The 3D printed Void Switch

Riskable’s 3D printed Void Switch uses a Hall effect sensor to determine the pressing of the key, a type of sensor that detects the presence of a magnetic field. Each switch mechanism features three individual 4 x 2mm magnets, one central static magnet for the levitator, and two moving magnets embedded in the switch’s slider.

The two moving magnets are placed above and below the static one, and serve to maintain an equilibrium between attraction and repulsion. Specifically, the lower magnet is what provides tactility, while the upper one is what provides the repulsive force acting in the opposite direction. In a conventional key switch, a spring would be used to deliver this counter-force.

Furthermore, the OpenSCAD files for the mechanism are customizable, whereby the user can modify the separation of the magnets. This is what allows for full control of the tactility and the counter-force of the keys.

Riskable recommends 3D printing the Void Switches using PETG filament due to the material’s deep sound profile and comparatively low coefficient of friction, which makes key presses smoother. However, a material like PLA will also work just fine. For those that want a quieter experience, the switches can also be paired with 3D printed TPU keycaps (92A or harder). TPU is flexible enough to absorb much of the sound energy but won’t buckle or bend under the force of a finger.

All of the open-source 3D files needed for the project can be downloaded on Riskable’s GitHub.

The open-source community can undeniably be a fountain of ingenuity, offering novel 3D printing applications at low costs. Earlier this month, YouTuber Akaki Kuumeri created a 3D printed adapter for the PS5 DualSense controller that enables users to play games one-handed. The add-on can be applied non-destructively to game controllers in order to allow for non-standard hand positions and make playing video games more accessible to those with physical disabilities.

Elsewhere, content creator Lucas VRTech has previously designed and 3D printed a pair of low-cost finger tracking gloves for use in virtual reality. Named LucidVR, the open-source gloves grant users the ability to precisely track their fingers without the use of dedicated VR controllers. Tallying up all of the component and filament costs, the LucidVR project cost Lucas just $22 ($11 per hand).

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an assembled Void Switch. GIF via Riskable.