3D printing has turned another, previously theoretical, structure into a solid object, and this time it is capable of deflecting bullets.

Inspired by the structure of tubulanes, first predicted in 1993, a team of researchers at Rice University have managed to create lightweight materials with high ballistic impact resistance and load‐bearing capabilities “regarded as,” the paper states, “a holy grail in materials design.”

Rice graduate student Seyed Mohammad Sajadi is the lead author of a paper discussing the tubulane-like structures. “There are plenty of theoretical systems people cannot synthesize,” explains Sajadi, “They’ve remained impractical and elusive. But with 3D printing, we can still take advantage of the predicted mechanical properties because they’re the result of the topology, not the size.”

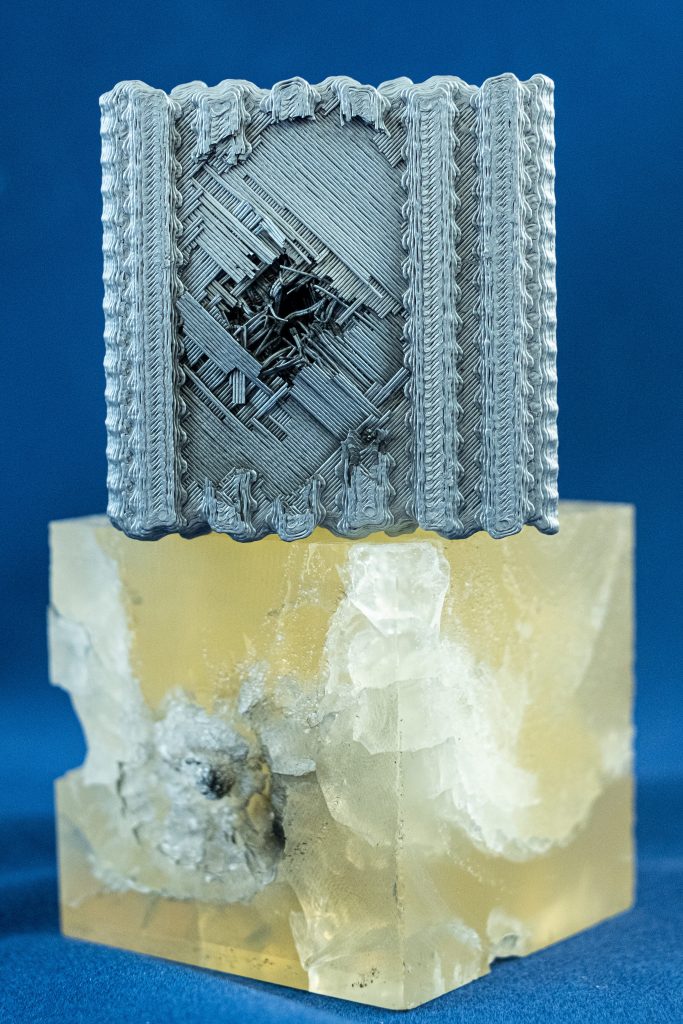

Objects designed based on the tubulanes were made from polymers, and proved to be ten times better at resisting a bullet than a solid block of the same material. The research paves the way for the development of materials with tunable mechanical responses.

3D printed materials in “a class of their own”

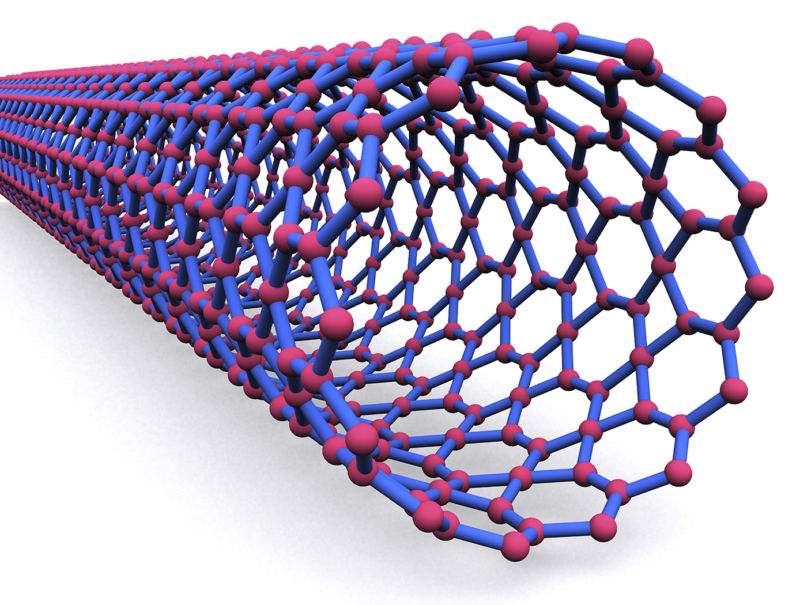

Tubulanes are complex structures based on fullerene tubules made from carbon. Fullerene tubules themselves, from the buckminsterfullerene or “buckyball“, consist of molecules that form a closed cylinder.

R.H.Baughmana and D.S.Galvão of Allied Signal Inc., New Jersey, and Instituto de Física, São Paulo were the first to predict the structure and properties of so-called tubulanes in 1993. Still, carbon tubulanes have yet to be created, but the new research from Rice is one of the first to use such structures as inspiration for physical objects.

In experimentation, Sajadi et al. created porous cubes using a 3D printed polymer, and tubulane-like designs. These cubes were then subjected to tests and compared to solid cubes made from the same base material.

When compressed, the tubulane pore structure allowed the cubes to collapse in upon themselves, instead of cracking as in the solid cube. A similar effect was observed when the blocks were hit with projectiles.

Firing at 5.8 kilometers per second, projectiles created cracks that propagated throughout the whole solid material block. In the tubulane cubes, the bullet stuck only within the second layer of the structure.

According to study co-author Peter Boul:

“The impact resistance of these 3D printed structures puts them in a class of their own.”

A new class of touch and durable materials?

As a preliminary study, the Rice team sees great potential for similar tubulane-like structures to be applied to the design of products made from different polymers, ceramics and metals. “The unique properties of such structures comes from their complex topology, which is scale-independent,” explains Rice alumnus and co-principal investigator Chandra Sekhar Tiwary. “Topology-controlled strengthening or improving load-bearing capability can be useful for other structural designs as well.”

“3D Printed Tubulanes as Lightweight Hypervelocity Impact Resistant Structures” is published in Small journal. The research is attributed to Seyed Mohammad Sajadi, Cristiano F. Woellner, Prathyush Ramesh, Shannon L. Eichmann, Qiushi Sun, Peter J. Boul, Carl J. Thaemlitz, Muhammad M. Rahman, Ray H. Baughman, Douglas S. Galvão, Chandra Sekhar Tiwary and Pulickel M. Ajayan.

Subscribe to the free 3D Printing Industry newsletter for the latest research developments. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows tubulane-like polymer structures created at Rice University (in grey) post-impact, compared to a solid block of the same material post projectile impact. Photo by Jeff Fitlow