Aaron Pratt is VP Marketing at Microboards Technology/Afinia. Here he shares his pragmatic views on 3D printing, how far this technology sector has come and where it can go. Coming from a 3D printer manufacturer, this feels like a breath of fresh air after being in a hot and steamy room for too long. A must read.

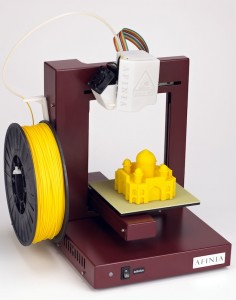

Almost exactly one year ago, we made the decision to enter the fray of 3D printing. What we saw then, and what we see now, was a disruptive technology, positioned to change business, that was beginning to make its way into the desktop market. Technologically speaking, we knew we were a late entrant. 3D printing, sometimes called Additive manufacturing, had been around for 30 years in one form or another. But marketwise, we saw a window of opportunity. Suddenly, garage tinkerers and back-room hobbyists were beginning to produce a product that met the economic requirements and piqued the interest of a much broader market than before. Given our expertise in commercializing new technology products in the B2B space, we decided to help the industry take a step past the tinker toy stage and offer a finished, supported device to users who were ready to try 3D printing but would need something that worked out of the box. And Afinia was born.

3D Printing Gains Media Prominence

The press’s annual pilgrimage to the Consumer Electronics Show gave 3D printing some good attention. While last year pundits were giving up on 3D TVs and yet another laptop, this year people got excited. Industry visionaries tried to imagine the new future. One drew a dotted line between 3D printers and the connected TV, another CES standout. CNET’s Rich Brown pointed out that while 3D Printing did not command the presence of a giant booth or a keynote, “every time I walked by a booth owned by a 3D printer manufacturer, the crowds were there in force. People are clearly excited by 3D printing…”

And hardly a day goes by without 3D printing landing in a local or national newspaper. 3D printing has been tied to practically every other pressing issue in the public’s mind – from the economy to gun control, and from medicine to outer space.

In medicine, 3D printing is being viewed as a potential game changer. Afinia’s 3D printer has already been used to make assistance devices for disabled children, and others have begun discussing the practicality of prosthetic limbs, custom hearing aids, and dental fixtures. But even further down the road, people are envisioning using the same concept – layering materials to produce a physical embodiment of a 3D design – to create biologically functional materials. Why not human tissue? And if human tissue, why not organs? To be sure, both the accuracy and the available materials have a long way to go before we are printing skin grafts or kidneys in the operating room. But all good things began with a vision.

On the more political side of the media feast are ethical questions. While recent tragedies prompt the population and congress to re-examine our relationship with guns, questions about the enforceability of legislation are challenged by the idea of at-home manufacturing. Already weapons parts have been made and even fired with limited success using prototyping equipment. One manufacturer quickly shied away from the debate by withdrawing their leased machine from an organization that had weapon production as their stated purpose. And one online community for sharing design files retired gun designs from their database, ostensibly for the same reasons. Here again, the technology has a long way to go before it can be used to fully manufacture a functional weapon. But the potential is there, and poses legal and ethical questions.

Even space has not been left untouched; people are dreaming of the possibilities of harvesting materials from asteroids or the moon and using them to print. Moving materials to space has long been a struggle for the exploratory visions of governments and science. Being able to utilize raw materials in space may solve one of the biggest obstacles to space access and eventual colonization.

The media is well-invested in the potentials of 3D printing. The prominent publication Wired Magazine has put some emphasis on it, even featuring industry spokesman and entrepreneur Bre Pettis on their cover. Chris Anderson, former editor-in-chief, has suggested possibilities and even written a book acknowledging the fledgling-industry-turned-cultural-movement. “Makers: The New Industrial Revolution” highlights the potential for custom fabrication and do-it-yourself creation highlights the potential for the next generation and the new economy.

The Public Reaction

But all of this seems so far-fetched! Is there a practical application for printing here and now? I’ve personally conducted almost a thousand demonstrations of a 3D printer, and watched the responses of people from all walks of life. The unified response is “Wow! That is cool”. Some have never heard of such a thing. Others have heard of it but had never seen it and shake their heads in amazement. A select few have already worked with the devices and are excited to see what comes next. But all of them wonder the same thing. “Can this do anything for me?”

The engineers, of course, are trying to figure out its limitations. I’ve talked to everyone from aerospace engineers to chemists. Some of them want to know how accurately it can print, what materials can be used, how big or small they can make a part, whether it can take water pressure, whether it will burn away if they use it for casting or a mold. Others just want to know where they can get the designs and how hard it is to design their own stuff.

There is the oft-suggested idea that replacement parts could be made with the machine. If you break a knob on your stove, lose a pull on a curtain, can you make a matching one? Sure! Of course, the manufacturer needs to provide the CAD file, the plastic needs to be strong enough, and the aesthetic won’t likely match in color or texture exactly, but hey! It’s a functional part! To be honest, I’ve seen very little of people replacing broken household parts with a 3D printer. The users are all either designers who want to print their own thing, or tinkerers who download other people’s files from Thingiverse to have one of their own.

So is this really a nascent industrial revolution? And how far off is it?

The Voices of Reason

A few pragmatic voices have suggested caution and a little bit of enthusiasm-curbing advice. Todd Grimm, one of the most well-known consultants covering the prototyping industry, has spoken out about the realities of 3D manufacturing in a few venues. A mechanical engineer by trade, Todd has been in rapid prototyping for 14 years and has even written a book (“User’s Guide to Rapid Prototyping”) on the subject.He has cautioned many in the field that 3D printing is overhyped and “not so rosy” as it has been declared. He refers to the “peak of inflated expectations” and criticizes the media for hyping Airbus’s 3D-printed aircraft (not until 2050 according to Airbus itself), or the animated film “ParaNorman”, which failed to save any money or time by using 3D prototyping.

Is it really worth it to quit your job and join the revolution? That may seem extreme, but not for Kai Backman, who quit Google to become the founder of Tinkercad. Or even the aforementioned Chris Anderson, who left Wired as Editor-in-Chief to join the movement. I have myself received inquiries from hundreds of people who would like to join on to Afinia. Some are sales people driven by the next big hit, others engineers who dream of being a part of the technology. All have stars in their eyes.

But part of the answer is, 3D Printing does have significant weaknesses.

Limitations in Today’s 3D Printers

Resolution has a similar issue. Most manufacturers are dealing in tolerances of a few thousandths; great for yesterday’s manufacturing, but nowhere near the precision requirements of say, a supplier of iPhone components.

The materials are limited to a few plastics. ABS plastic, by far the most popular, is relatively safe but not food safe (and the domestic kitchen is one place that seems to see the most constant customization and design. Boutique Kitchen stores and Saturday morning infomercials are littered with patent-pending devices that are sure to be a hit in your next garage sale.) PLA plastic, which is somewhat more food safe and biodegradable (it’s made from plant starches) is more finicky to work with. Of course, for printers that have no heated bed, PLA is the only option; ABS requires a slightly more sophisticated printer. (Product plug here: Afinia’s product does have a heated bed, so it works well with ABS). Every day I have someone ask about other materials. Nylon. Wax. Metal. The answer is, unfortunately, no. Nylon may be close, but it’s not likely you’ll see metal or wax in a desktop printer for a while yet. (People want wax for doing castings; a common request is to be able to create custom jewelry, for which a plastic mold or cast would not work.)

Tensile strength is another huge limitation of the technology. ABS, of course, is fairly strong as plastic goes. But most of the desktop additive technologies out there are extruding a plastic wire to create a layered object. The fusion between the layers of the model is a weak point. In two dimensions the product is reasonably strong, but in the vertical or z-axis of a printed model, you can generally break it with your hand. There are other technologies out there for 3D printing that are not fused by heat, but they are a ways off from becoming an affordable home desktop printer.

Speed is the last big frontier; Prototyping is a notoriously slow process, regardless of the technology used. It is economically efficient because you are creating only one part. When it is a test part, that is just fine. But as soon as you need a quantity, it is worth the investment in tooling to be able to mass produce parts and reach economies of scale. If, when you picture 3D printers in your mind, you are envisioning Captain Picard ordering his “Tea, Earl Grey, Hot” from his Star Trek Replicator, you may want to think ahead. Captain Picard would likely have to order his tea a day or two in advance using our current technology. And it can only print the tea cup and saucer, not the tea itself.

3D Printing as a Disruptive Technology

Now, with that little discouragement out of the way, 3D Printing does bear the signature of a disruptive technology. In fact, when assessing a new technology, the existence of one or more of these types of obstacles are actually indicators of a potential disruptive technology! One of the thought leaders in technological evolution, Harvard’s Clayton Christensen, has pointed out that there is a time to invest as a business in these types of technology. In his book, “The Innovator’s Dilemma”, he helps the innovator identify disruptive technologies and recognize the ways to avoid being beaten by it. As he points out, there is a time when it is not right to listen to customers, a time when the right choice is to develop lower-performance products that promise lower margins, and a time to pursue small markets at the expense of large, lucrative ones. 3D Printers could easily meet the parameters he establishes.

Proposing a similar point but from a different perspective, Geoffrey Moore has made a career out of helping companies bridge the product gap that often occurs in technology adoption. He helps point out the time cleft that exists between enthusiastic early-adopters and actual professional users of a technology. His consulting organization offers a rubric for assessing technologies and for establishing a strategy for bringing the technology to markets with reference accounts (“bowling pins”) that will serve as a beachhead for the technology to eventually become mainstream. And here’s the exciting part: By my calculation, 3D Printers are entering that phase!

Here are just four market-based evidences that 3D Printers are about to make the leap to the mainstream.

First, they are evolving away from being a hobbyist device. Many of the new users are vocal about their frustration with tinkering. And while the tinkerers are not happy about the departure that Afinia and others have made from being an open-source, modification-friendly platform, hundreds of others are buying it with gusto.

Second, the Education Market is buying. Across the country, high school programs are looking for ways to incorporate 3D printing in their curricula. I know one teacher who bought his own to put in the classroom, not a small sacrifice on a teacher’s salary. Another technical college just placed 12 of our H-Series printer in the classroom. And we’ve placed units at many, many more schools. 3D printing is practical for them, not because the output is practical, but because it is enabling their programs. While schools struggle to find creative ways to re-engage students and make our country competitive in our STEM programs (Science-Technology-Engineering-Math), a 3D printer does it almost singlehandedly. It opens imaginations.

Third, the prototyping industry is buying. We’ve had many discussions with organizations who own a larger, more highly featured form of prototyping technology (bigger envelope, better resolution, and so on). In almost every case, the idea of offloading the machine was attractive to them. The machine is either utilized so constantly that they need a quick fix for a first-proof part or a test-fit part, or the cost of operating it is so high that they haven’t been utilizing it for some types of work. The desktop 3D printer gives output that is “good enough” for what they need. To be sure, a 3D printed part isn’t a production part, and in some applications falls short of even being a prototype. But it’s useful and paying for itself with a few people. And those few are growing.

Fourth, an ancillary economy is emerging. Design software is coming down in price. More varieties of design software are emerging at entry-level price points. Other 3D devices (scanners and cameras) are enabling the possibilities. Online consortia of content providers are mobilizing around the “.stl” and “.dxf” file formats, providing libraries of free content to customize or print. People are discussing different business models for monetizing designs and design services. Even the recycling economy is getting going; one company has designed a device that recycles used plastic into filament again.

The Real Promise of 3D Printing

So there it is. While I don’t know if there will ever be a 3D printer in every home, or even sitting next to the 1-hour photo developing counter at your corner drugstore or hardware store, I do know it is growing. The trajectory is good. The right users are playing with it. Schools are starting to teach about it. The Consumer Electronics Association identified it as one of the five technology trends to watch, while Wohlers Associates projects it going from $1.7 billion dollars in 2011 to $3.7 billion dollars in 2015.

All in all, that’s pretty promising.

This article was originally published on Afinia’s website. Reproduced here with permission.