3D printed robots have been around for a while but the latest generation of robots brings something new to the table. The most recent advances have been labelled ‘Soft Robotics’ and the purpose of these developments is to enable robots to more closely mimic the physical behaviour of humans. Previously, this has been limited by material characteristics and manufacturing methods, however 3D printing, more specifically the Polyjet process from Objet in combination with Digital materials, has seen a major breakthrough on this front.

Traditionally even the most sophisticated robots have been limited in terms of movement due to the stiff materials necessary to construct them — usually hard plastics or metals. However, two researchers from the University of West England (UWE) have been working with a range of new technologies to overcome this limitation. As a result, Peter Walters and David McGoran of the 3D Printing Lab at the university’s Center for Fine Print Research, have been able to create an ‘artificial muscle’ that more closely resembles the movement and function of more organic creatures such as an octopus. The ‘artificial muscles’ are constructed from a Shape Memory Alloy material or Biometal, which contracts when heated by an electric current. The biometal material is in the form of a wire, which can then be embedded within a larger, flexible part that can move in multiple directions when stimulated.

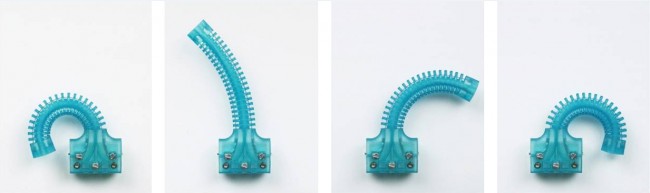

3D printing has been a key enabler for developing the external flexible part to house the Biometal wires, in the shape of tentacles. These tentacles are, of necessity, a complex shape, incorporating cavities for the wires and no traditional manufacturing methods were suitable for production. The tentacles were 3D printed on an Objet 3D printer — the only process commercially available that is able to 3D print both rigid and rubber-like materials together within the same structure. The Objet-printed parts are the blue sections, which were printed using the TangoPlus material, and then subsequently dyed blue after 3D printing and cleaning.

More information on the 3D printed tentacle work by Peter Walters’ and David McGoran’s can be found here.